High-quality non-polar AlGaN micro-nano composite structure and processing method thereof

A technology of micro-nano composite structure and processing method, applied in the field of electronic information engineering, can solve problems such as restricting non-polar AlGaN-based ultraviolet rays, and achieve the effects of solving in-plane stress anisotropy, improving crystal quality, and reducing dislocation density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The specific steps of the first processing method based on the above-mentioned high-quality non-polar AlGaN micro-nano composite structure of the present invention are as follows:

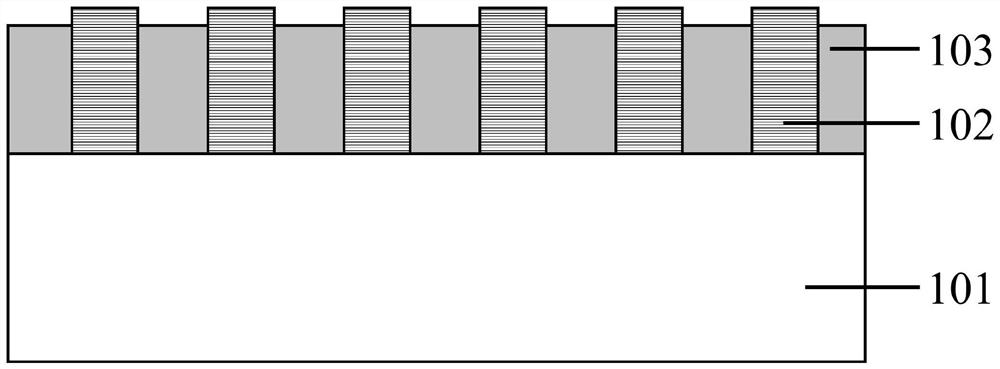

[0039] (1) Firstly, a layer of solid dielectric thin film is prepared on the substrate 101, the thickness of the solid dielectric thin film is the height of the columnar solid dielectric array structure 102;

[0040] (2) Perform an etching process on the columnar dielectric film, and etch the solid dielectric film prepared in step (1) into a columnar solid dielectric array structure 102 of a specified shape;

[0041] (3) Based on the epitaxial growth technology, the columnar solid medium array structure 102 on the substrate 101 gaps grows hole-shaped non-polar Al x Ga 1-x N layer 103;

[0042] (4) To complete the growth hole-shaped non-polar Al x Ga 1-x The non-polar AlGaN micro-nano composite structure of the N layer 103 is subjected to heat treatment at a temperature greater than 800°C...

Embodiment 2

[0044] The specific steps of the second processing method based on the above-mentioned high-quality non-polar AlGaN micro-nano composite structure of the present invention are as follows:

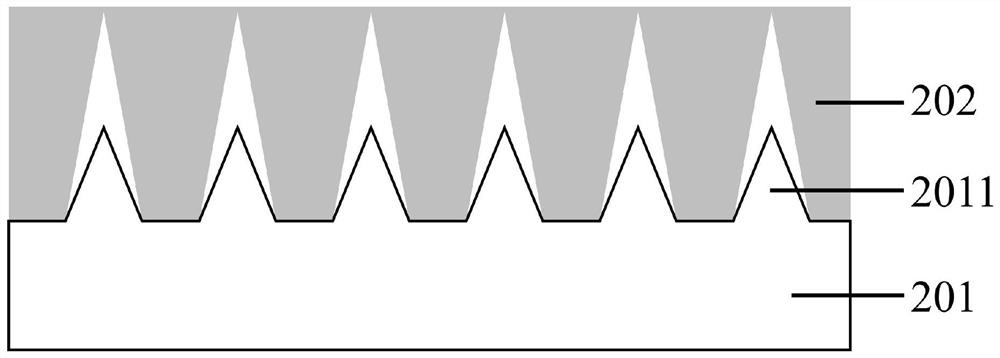

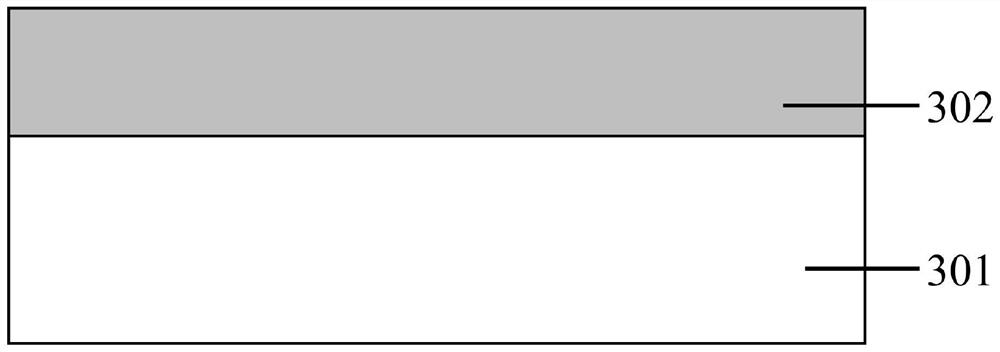

[0045] (1) First prepare a layer of non-polar AlGaN film on the substrate 101, the thickness of which is greater than or equal to the hole-shaped non-polar Al x Ga 1-x the thickness of the N layer 103;

[0046] (2) Perform an etching process on the prepared non-polar AlGaN film, and etch it to form holes with a specified shape inside and distributed in an array;

[0047] (3) On the basis of a non-polar AlGaN film containing holes of a specific shape, fill the holes with a solid medium by coating technology to form a precursor of the columnar solid medium array structure 102; on this basis, sequentially perform etching, grinding and polishing processes , to ensure leakage of the non-polar AlGaN thin film, and to prepare the porous non-polar Al containing the columnar solid dielectric array...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com