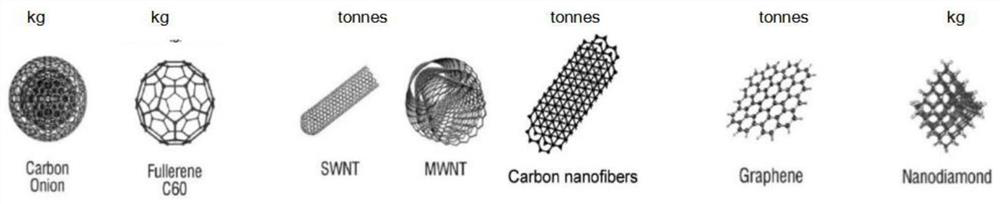

Intelligent green manufacturing system for coal-based nanocarbon polycrystalline formula product

A green manufacturing, nano-carbon technology, applied in manufacturing computing systems, nanotechnology, nanotechnology, etc., can solve the problems of not paying attention to intelligent industrial automation, production revenue management, not considering manufacturing engineering, logistics engineering and distribution engineering, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

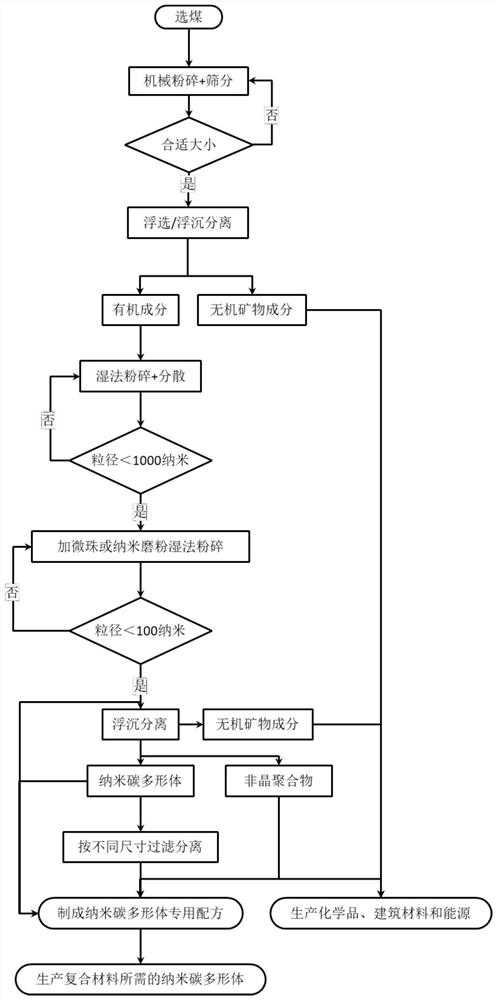

Method used

Image

Examples

example 1

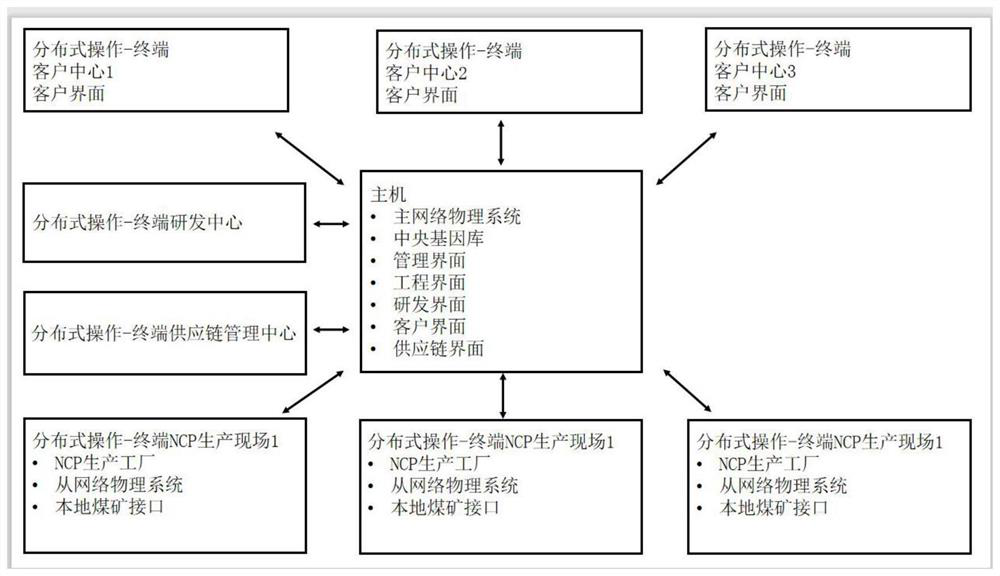

[0137] In this embodiment, the configuration and operation of the intelligent manufacturing system are shown to illustrate the practicability of the present invention. This exemplary smart manufacturing system is located in China and is producing products with coal-based nanocarbon polymorph formulations. The main station of this system is located in Foshan, Guangdong. This system has two distributed operation terminals, one in Beijing and one in Handan City, Hebei Province. Figure 5 A map of the facility's location is shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com