Double-layer sediment remediation capsule and application thereof

A bottom sludge, double-layer technology, applied in biological sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of microbial loss, large amount of engineering, high investment demand, and prolong the action time. , the effect of improving the ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

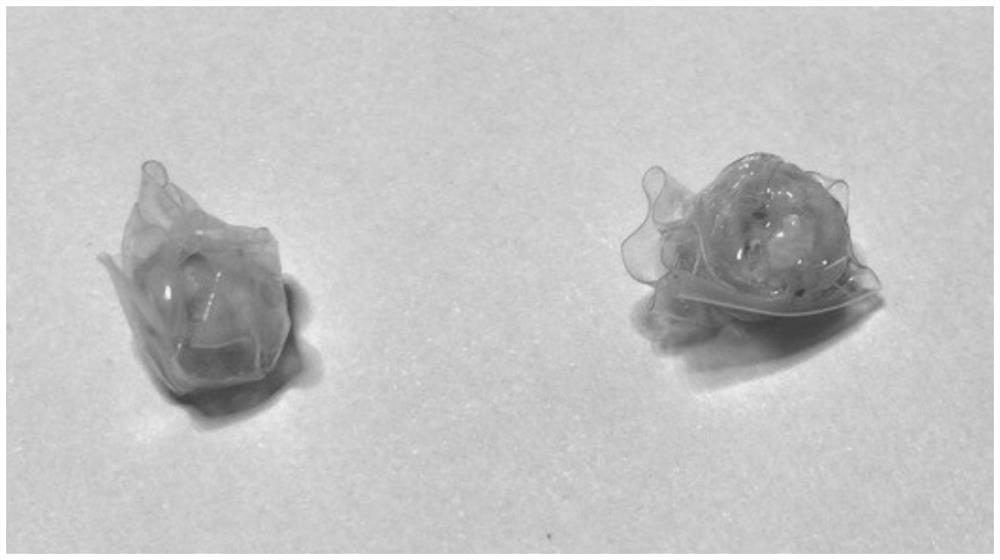

[0052] The parts by mass of the components of the double-layer bottom mud restoration capsule in this embodiment are: the components in the coating layer of the outer bacterial solution are: 1 part of sodium alginate, 4 parts of polyacrylamide, 25 parts of EM bacterial solution, 60 parts of water; each component in the inner adsorption material layer is: 1 part of sodium alginate, 6 parts of calcium peroxide, 6 parts of diatomaceous earth, 8 parts of fine sand, and 75 parts of water.

[0053] The preparation method of the above-mentioned double-layer bottom mud restoration capsule comprises the following steps:

[0054] (1) Sodium alginate is completely dissolved into floc colloid with water, mixed with calcium peroxide, diatomaceous earth and fine sand, stirred and mixed to form floc, and cross-linking reagent (calcium chloride solution) is added to carry out cross-linking React for 15 minutes to obtain the inner layer of adsorption material layer;

[0055] (2) Dissolve sodi...

Embodiment 2

[0057] The mass parts of the components of the double-layer bottom mud restoration capsule in this embodiment are: the components in the outer bacterial liquid coating layer are: 4 parts of sodium alginate, 8 parts of polyacrylamide, 30 parts of EM bacterial liquid, 80 parts of water; the components in the inner adsorption material layer are: 4 parts of sodium alginate, 15 parts of calcium peroxide, 15 parts of diatomaceous earth, 15 parts of fine sand, and 90 parts of water.

[0058] The preparation method of the above-mentioned double-layer sediment restoration capsule is as described in Example 1.

Embodiment 3

[0060] The mass parts of the components of the double-layer bottom mud restoration capsule in this embodiment are: the components in the outer bacterial liquid coating layer are: 1 part of sodium alginate, 2 parts of polyacrylamide, 20 parts of EM bacterial liquid, 60 parts of water; each component in the inner adsorption material layer is: 1 part of sodium alginate, 6 parts of calcium peroxide, 6 parts of diatomaceous earth, 8 parts of fine sand, and 75 parts of water.

[0061] The preparation method of the above-mentioned double-layer sediment restoration capsule is as described in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com