Thermal insulation mortar taking magnesium phosphate cement layer-EPS and phosphate-expanded perlite as aggregate and preparation method

A technology of magnesium phosphate cement and expanded perlite, which is applied in the field of thermal insulation materials to achieve the effects of not easy to agglomerate, easy to store, and to save adhesives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] A thermal insulation mortar with magnesium cement layer-EPS particles and magnesium salt-expanded perlite as aggregates, including the following components in parts by mass: 35 parts of dead-burned magnesium oxide, 15 parts of fly ash, magnesium cement layer-EPS 9 parts of granules, 40 parts of salt-filled expanded perlite, and 1 part of glass fiber;

[0060] Prepared by:

[0061] Step 1, the NH 4 h 2 PO 4 Grind to less than 0.125mm NH 4 h 2 PO 4 powder;

[0062] Step 2, the NH 4 h 2 PO 4 The powder is mixed with expanded perlite, and then passed through a 1mm sieve to screen out the rich NH 4 h 2 PO 4 Powdered expanded perlite;

[0063] Step 3, the NH 4 h 2 PO 4 Add water to dissolve to form a saturated solution, put the EPS particles into the saturated solution and soak for 0.5h-4h, then remove the EPS particles and roll them in inactive magnesia to make the surface contaminated solution react with the re-burned magnesia to form a coating layer of magn...

Embodiment 2

[0067] A thermal insulation mortar with magnesium cement layer-EPS particles and magnesium salt-expanded perlite as aggregates, including the following components in parts by mass: 60 parts of dead-burned magnesium oxide, 20 parts of fly ash, magnesium cement layer-EPS 2 parts of granules, 10 parts of salt-filled expanded perlite, 8 parts of glass fiber;

[0068] Prepared by:

[0069] Step 1, the KH 2 PO 4 Grind to less than 0.125mm NH 4 h 2 PO 4 powder;

[0070] Step 2, the KH 2 PO 4 The powder is mixed with expanded perlite, and then passed through a 1mm sieve to screen out the rich KH 2 PO 4 Powdered expanded perlite;

[0071] Step 3, add EPS particles to water to fully wet, NH 4 h 2 PO 4 Add water to dissolve to form a saturated solution, put the granules into the saturated solution and soak for 0.5h-4h, then remove the EPS granules and roll them in the inactive magnesia to make the surface stained solution react with the reburned magnesia to form a coating la...

Embodiment 3

[0075] Others are consistent with Example 1, except that the magnesium cement layer-EPS particles in step 3 are prepared by using the coating system through the following method:

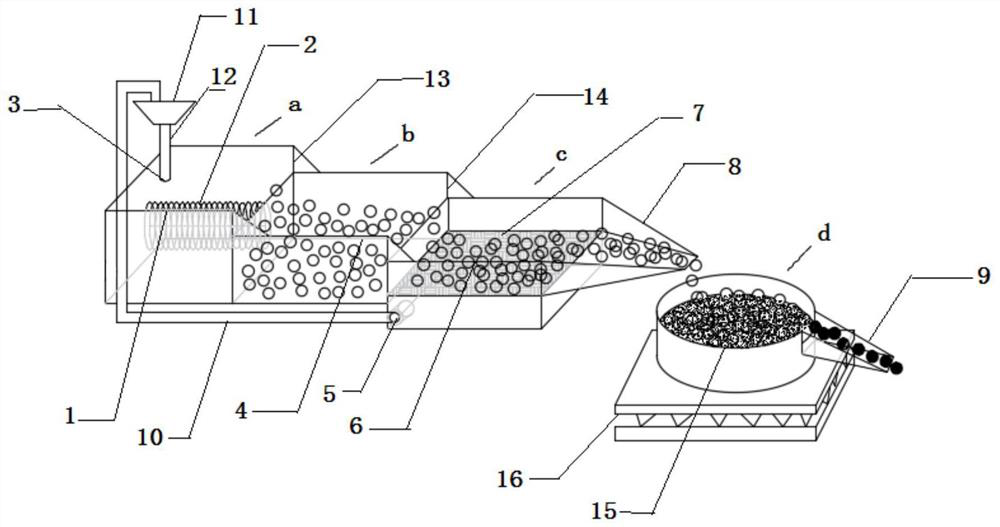

[0076] The coating system includes a stirring device a, an immersion device b, a water removal device c, and a coating device d connected in sequence, wherein:

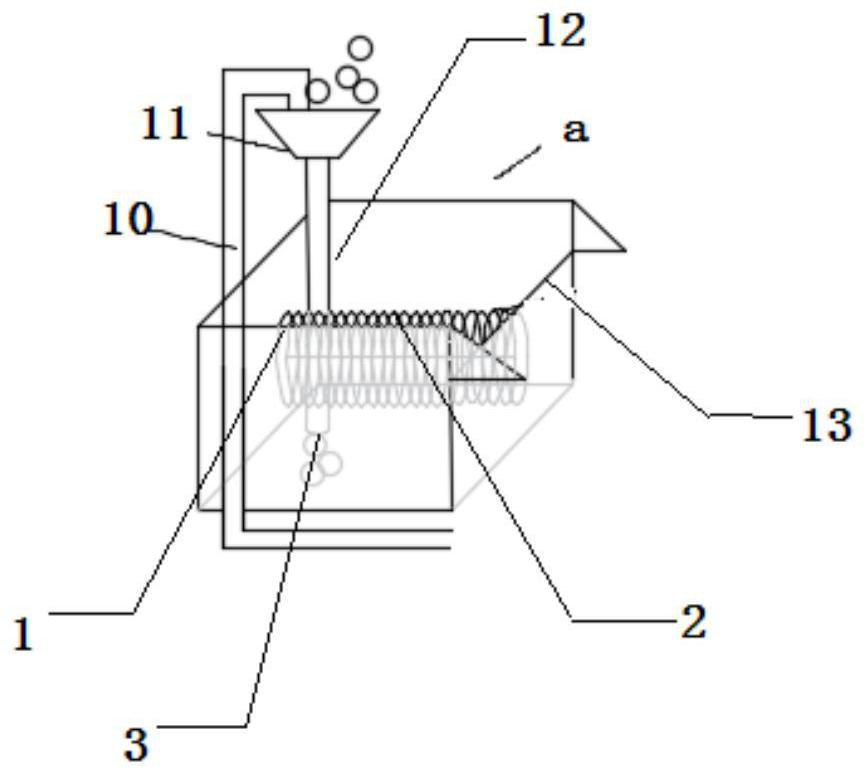

[0077] The stirring device a includes a stirring tank 1 and a stirring mechanism 2 arranged in the stirring tank 1, the top of the stirring tank 1 is provided with a feeding mechanism, and the discharge port 3 of the charging mechanism is located in the stirring tank 1 Close to the bottom position, the top of the stirring tank 1 is provided with a discharge port 13;

[0078] The immersion device b includes a immersion pool 4, the inlet of the immersion pool 4 communicates with the discharge port 13, and the immersion pool 4 is also provided with a discharge port 14;

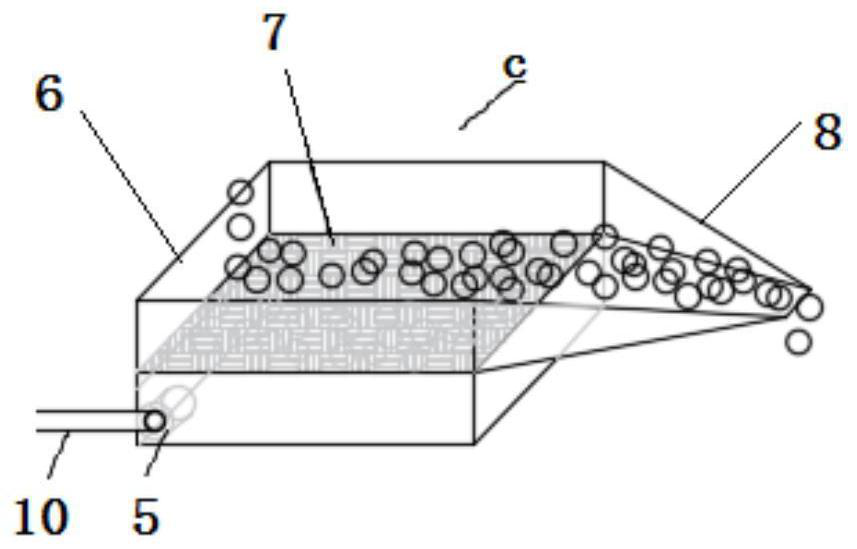

[0079] The water removal device c includes a water removal tank 6 and a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com