Formula and preparation method of autoclaved fly ash brick

An autoclaved fly ash brick and fly ash technology, applied in the field of building materials, can solve the problems of difficult transportation and environmental protection management and control, high cost of solid waste treatment, single treatment method, etc., so as to solve the problem of environmental pollution and realize the utilization of solid waste. , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The present embodiment provides a kind of formula of autoclaved fly ash brick, comprises according to mass percentage:

[0039] Coarse slag mixture, including: 10% to 30% of the first coarse slag, produced by the single-nozzle gasifier; 10% to 30% of the second coarse slag; 35% to 45% of fly ash; and

[0040] The balance of carbide slag;

[0041] Wherein, the particle size distribution of the particles in the coarse slag mixture, according to mass percentage, includes:

[0042] 57% to 66% below 1.2mm;

[0043] 29% to 36% between 1.2mm and 5mm.

[0044] The first coarse slag in the present invention is the hydrated slag discharged from the slag discharge lock hopper at the bottom of the gasifier after the pulped coal particles are melted, chilled and condensed under high temperature and high pressure conditions in the single nozzle gasifier , the main component is SiO 2 、Al 2 o 3 and Fe 2 o 3 , wherein, according to the mass percentage, the particles with a parti...

Embodiment 2

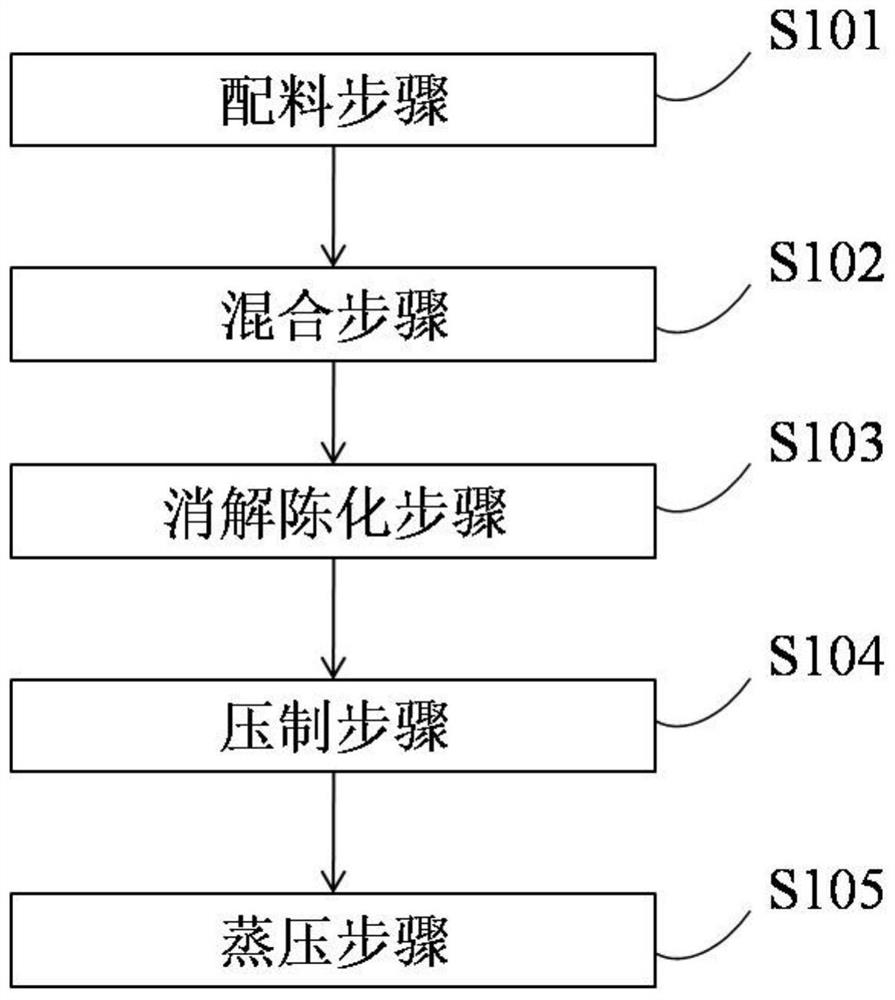

[0050] The present embodiment provides a kind of preparation method of autoclaved fly ash brick, such as figure 1 shown, including steps:

[0051] S101 batching step: weighing the first coarse slag, the second coarse slag, fly ash and carbide slag according to the formula of the present invention;

[0052] S102 mixing step: mixing the first coarse slag, the second coarse slag, fly ash and carbide slag, adding water and stirring to obtain a mixed material. In some embodiments, the moisture content of the mixed material is controlled between 13% and 16%;

[0053] S103 digestion and aging step: digest and age the mixed material in a digestion bin with a larger volume. In some embodiments, the digestion aging time is between 30min and 60min;

[0054] S104 Pressing step: press the digested and aged mixed material, and form brick adobe after several times of pressurization and exhaust, wherein the pressurization pressure is between 140bar and 160bar, and the pressing time is betw...

Embodiment 3

[0076] This embodiment provides a kind of embodiment of the preparation method of the autoclaved fly ash brick, comprising steps:

[0077] 1) batching step: weighing 20% of the first coarse slag, 20% of the second coarse slag, 40% of fly ash and 20% of calcium carbide slag according to the mass percentage;

[0078] 2) Mixing step: mix the first coarse slag, the second coarse slag, fly ash and carbide slag and add water and stir to obtain the mixed material; during specific implementation, the first coarse slag, the second coarse slag and the calcium carbide slag are passed through the The bucket conveyor is transported to the batching silo, and the siliceous material fly ash stored in the ash silo is transported to the fly ash metering hopper through the screw conveyor at the bottom of the ash silo, and the material is accurately discharged and measured according to the established ratio. After the metering is completed, the material is transported to the mixer by a belt con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com