An environmentally friendly plastic with controllable transparency and multi-color patterns and its preparation method

An environmentally friendly plastic and transparent technology, applied in the field of plastic alloy preparation, can solve the problems of limited use range, environmental pollution, long production cycle, etc., and achieve the effects of low requirements for injection molding conditions, cost reduction, and good results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

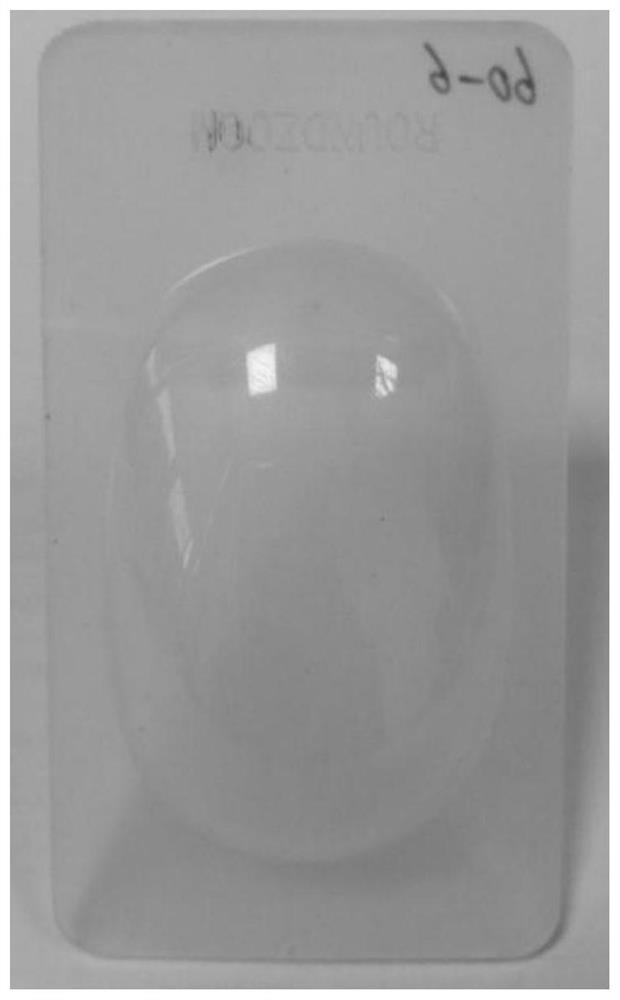

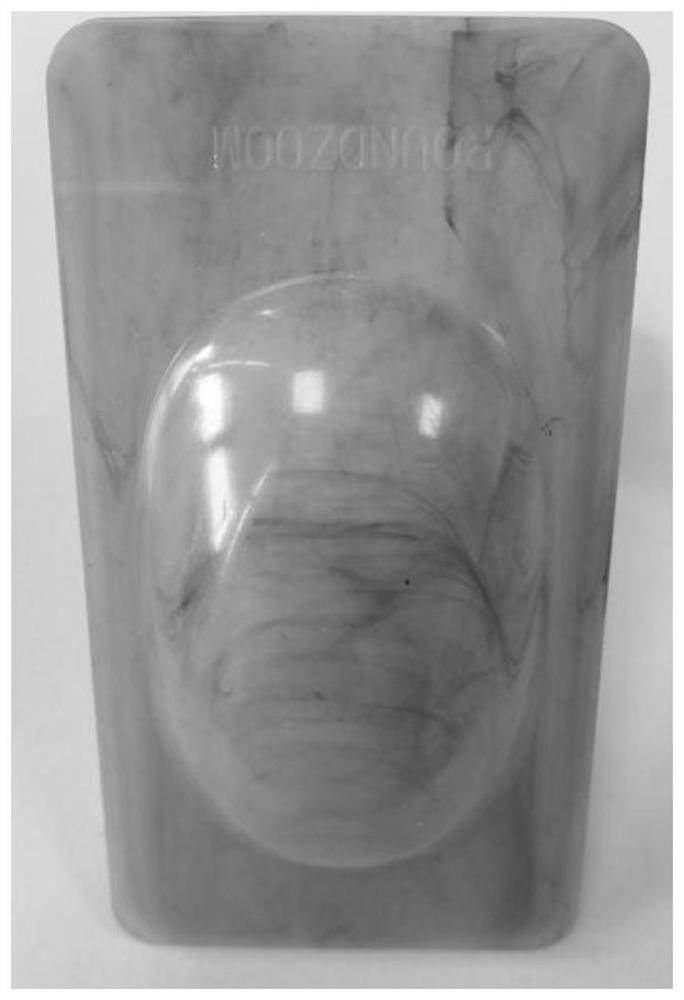

Image

Examples

Embodiment 1

[0053] The components and proportions of Example 1 are shown in the table below. The specific preparation process is the same as that of the comparative example, the difference is that the stirring speed is 2000 rpm, and samples are taken for observation after 3 minutes and 6 minutes of initial mixing. The final temperature of initial mixing is 65°C. The screw speed of the unit was adjusted to 200rpm.

[0054] Table 2: Component composition and proportioning ratio of embodiment 1

[0055]

Embodiment 2

[0057] The components and proportioning ratio of Example 2 are shown in Table 3. Its concrete preparation process is identical with embodiment 1.

[0058] Table 3: Component composition and proportioning ratio of embodiment 2

[0059] name parts by weight name parts by weight SL-803G 400 1010 1 GPPS 600 1076 2 HIPS 5 168 2 SAN 100 DSTDP 1 MS 5 UV-531 1 SIS 10 HSt 1 EBS 5 cast 1 Interacid amide 2 Microcrystalline Wax 1 Transparent organic color masterbatch 1-3

Embodiment 3

[0061] The components and proportioning ratio of Example 3 are shown in Table 4, and its specific preparation process is the same as that of Example 1.

[0062] Table 4: Component composition and proportioning ratio of embodiment 3

[0063]

[0064]

[0065] Table 5: performance comparison table of each embodiment

[0066] comparative example Example 1 Example 2 Example 3 Yield strength (Mpa) 38.8 43.2 46.0 26.5 Yield elongation (%) 9.0 7.2 2.4 0.9 Fracture stress (Mpa) 42.0 46.2 54.0 31.0 Elongation at break (%) 60.0 56.7 20.5 72.4 Maximum bending strain (%) 4.5 3.7 2.0 1.4 Flexural modulus (Mpa) 1300 1600 1850 1190 Bending strength (Mpa) 32.2 28.5 22.0 13.5 Cantilever impact strength (KJ / ㎡) 7.8 6.9 5.6 4.8 Vicat softening point (℃) 89.4 91.4 86.4 86 Hardness (Shore D) 79 81 83 73 Melt index (200℃, 5kg) 7.8 9.3 10.2 7.8 Transmittance (%) 90 89 34 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com