Converter pure dry dedusting system integrating high-temperature constant-temperature treatment, high-temperature purification and waste heat recovery

A technology of waste heat recovery and dry dust removal, which is applied in the direction of furnace, waste heat treatment, furnace components, etc., can solve the problem of high alternating thermal stress of vaporization cooling flue and waste heat recovery device, secondary pollution of electrostatic precipitator operating posts, and daily maintenance , maintenance workload and other problems, to improve the reliability and stability of work operation, water saving, electricity saving and environmental protection, and the effect of improving energy utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

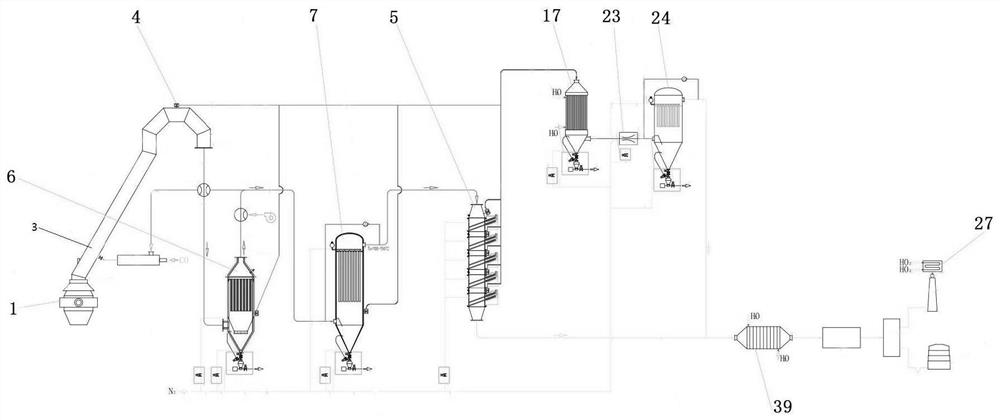

[0105] Such as figure 1 As shown, the converter pure dry dedusting system integrating high temperature constant temperature, high temperature purification and waste heat recovery of the present invention includes vaporization cooling flue 1, high temperature phase change heat storage device 6, high temperature resistant pulse jet ceramic filter tube dedusting system Device 7, waste heat recovery system, explosion venting fume collection and treatment system.

[0106] Before the converter 1 carries out oxygen blowing smelting, the water-cooled three-way high-temperature reversing valve in the system acts to connect the high-temperature flue gas outlet of the vaporization cooling flue 3 to the high-temperature phase-change heat storage device 6, and at the same time, the water-cooled two The high-temperature reversing valve acts to connect the high-temperature flue gas outlet of the high-temperature phase-change heat storage device 6 to the high-temperature-resistant pulse-jet c...

Embodiment 2

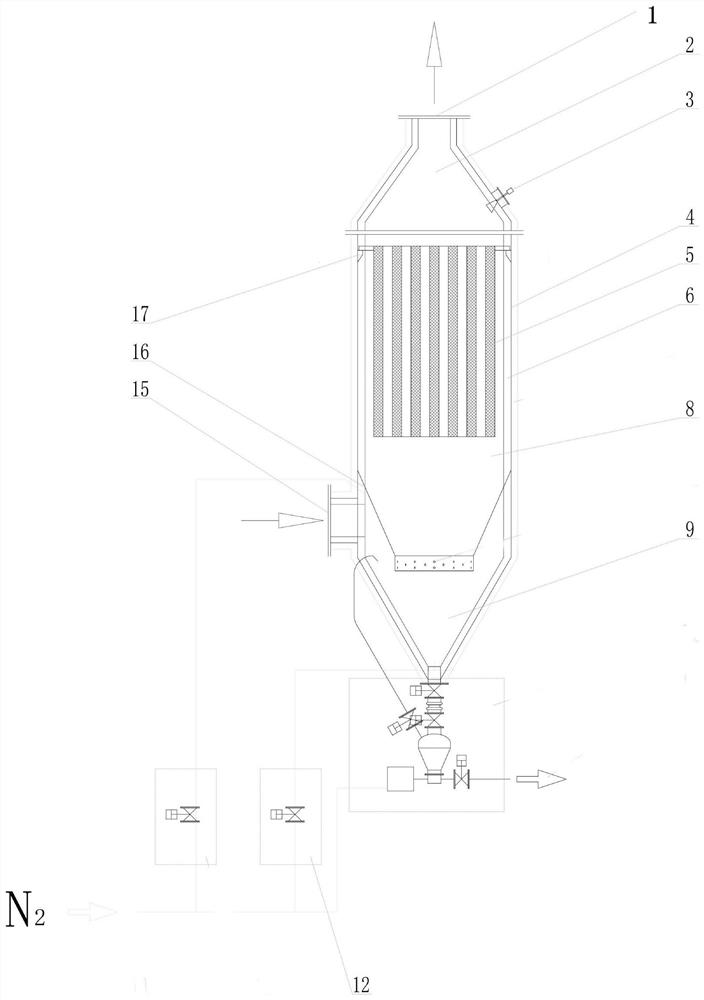

[0113] Such as figure 2 As shown, the high-temperature phase-change heat storage device includes a circular shell 2-4 and an ash hopper 2-9, wherein the shell includes an upper box 2-2 and a middle box 2-8, and the The middle box 2-8 is provided with a high-temperature phase-change heat storage core 2-5, and the upper box 2-2 is located on the upper part of the middle box 2-8 with the high-temperature phase-change heat storage core 2-5 ; The middle box 2-8 and the upper box 2-2 can be opened, so as to install, replace, maintain and repair the high temperature phase change heat storage core 2-5 arranged in the middle box; The bucket 2-9 is located below the middle box 2-8;

[0114] The upper box 2-2 is provided with a high-temperature flue gas outlet 2-1, the middle box 2-8 or the ash hopper 2-9 is provided with a high-temperature flue gas inlet 2-15, and the high-temperature flue gas The entrance 2-15 is connected along the tangential direction of the circular shell, and is...

Embodiment 3

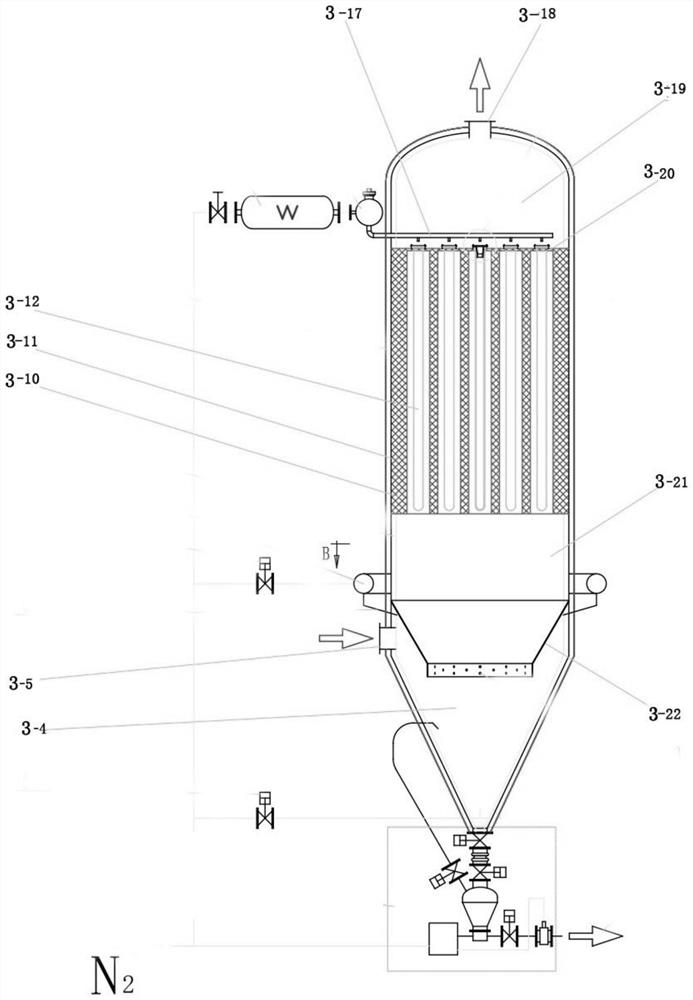

[0126] Such as image 3 As shown, the high-temperature constant temperature pulse-jet ceramic filter tube dust removal device includes a circular shell 2-11 and an ash hopper 2-4, wherein the shell 2-11 includes a middle box 2-21 and a An upper box 2-19 above the middle box 2-21 and separated by a partition 2-20; the ash hopper 2-4 is located below the middle box; the upper box is provided with a net high temperature The flue gas outlet 2-18; the middle box 2-21 or the ash hopper 2-4 is provided with a dust-laden high-temperature flue gas inlet 2-5; the dust-laden high-temperature flue gas inlet 2-5 adopts a circular The casing is connected in the tangential direction, and together with the primary cyclone separation / air distribution device 2-22 for dust-laden flue gas installed in the middle box or ash hopper, the high-temperature dust-laden flue gas entering the dust collector is initially separated. , Settling treatment; The described dust-laden flue gas primary cyclone se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com