Fabric softening finishing agent and preparation method thereof

A technology for fabric softening and finishing agent, applied in fiber treatment, textile and papermaking, improved hand-feeling fibers, etc., can solve the problems of poor dispersion uniformity, yellowing, sticking of nano-diatomite, etc., and achieve the effect of soft finishing Good, avoid yellowing, soft effect good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

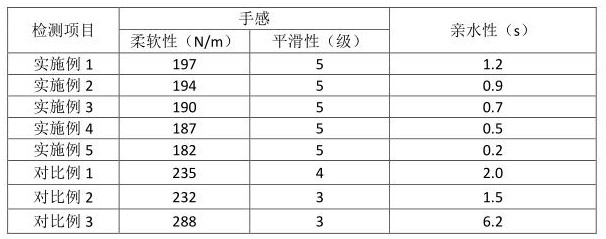

Examples

Embodiment 1

[0033] Embodiment 1 provides a kind of preparation method of fabric softening finishing agent, is characterized in that, comprises the steps:

[0034] Step S1, epoxy-modified bis(2-hydroxyethyl)amino(trimethylol)methane: adding bis(2-hydroxyethyl)amino(trimethylol)methane and epichlorohydrin to the organic solvent , stirred and reacted at 30°C for 4 hours, and then the solvent was removed by rotary evaporation to obtain an intermediate product;

[0035] Step S2, preparation of modified amino silicone oil: add amino silicone oil, the intermediate product prepared through step S1, and the basic catalyst to isopropanol, reflux and stir at 70°C for 3 hours, and then spin evaporate to remove isopropanol , and adding water therein, separating the liquids, taking the oil phase, and removing the water by rotary evaporation to obtain the modified amino silicone oil;

[0036] Step S3, ion exchange: add the modified amino silicone oil and polyoxyethylene lauryl ether carboxylic acid pre...

Embodiment 2

[0044] Embodiment 2 provides a kind of preparation method of fabric softening and finishing agent, is characterized in that, comprises the steps:

[0045] Step S1, epoxy-modified bis(2-hydroxyethyl)amino(trimethylol)methane: adding bis(2-hydroxyethyl)amino(trimethylol)methane and epichlorohydrin to the organic solvent , stirred and reacted at 33°C for 4.5 hours, and then the solvent was removed by rotary evaporation to obtain an intermediate product;

[0046] Step S2, preparation of modified amino silicone oil: add amino silicone oil, the intermediate product produced through step S1, and the basic catalyst to isopropanol, reflux and stir at 73°C for 4 hours, and then spin evaporate to remove isopropanol , and adding water therein, separating the liquids, taking the oil phase, and removing the water by rotary evaporation to obtain the modified amino silicone oil;

[0047] Step S3, ion exchange: Add the modified amino silicone oil and polyoxyethylene lauryl ether carboxylic ac...

Embodiment 3

[0055] Embodiment 3 provides a kind of preparation method of fabric softening finishing agent, is characterized in that, comprises the steps:

[0056] Step S1, epoxy-modified bis(2-hydroxyethyl)amino(trimethylol)methane: adding bis(2-hydroxyethyl)amino(trimethylol)methane and epichlorohydrin to the organic solvent , stirred and reacted at 35°C for 5 hours, and then the solvent was removed by rotary evaporation to obtain an intermediate product;

[0057] Step S2, preparation of modified amino silicone oil: add amino silicone oil, the intermediate product prepared through step S1, and the basic catalyst to isopropanol, reflux and stir at 75°C for 4.5 hours, and then spin evaporate to remove isopropanol , and adding water therein, separating the liquids, taking the oil phase, and removing the water by rotary evaporation to obtain the modified amino silicone oil;

[0058] Step S3, ion exchange: add the modified amino silicone oil and polyoxyethylene lauryl ether carboxylic acid p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com