Manufacturing method of self-aligned double-groove gallium arsenide field effect transistor

A technology of gallium arsenide field and fabrication method, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as overlay offset, affecting device performance, etc., to ensure alignment, reduce process, The effect of stable device performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

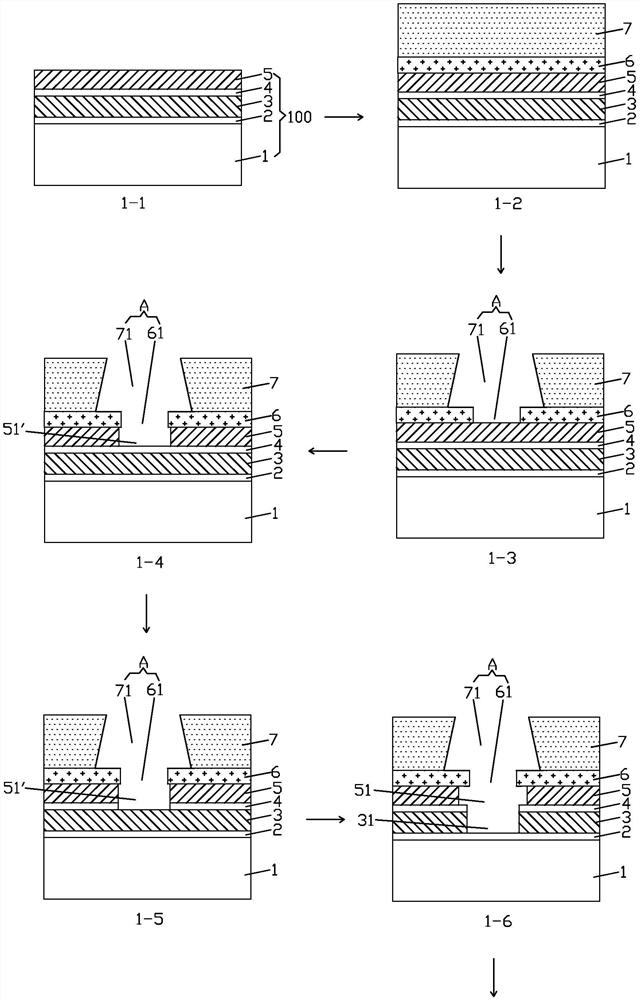

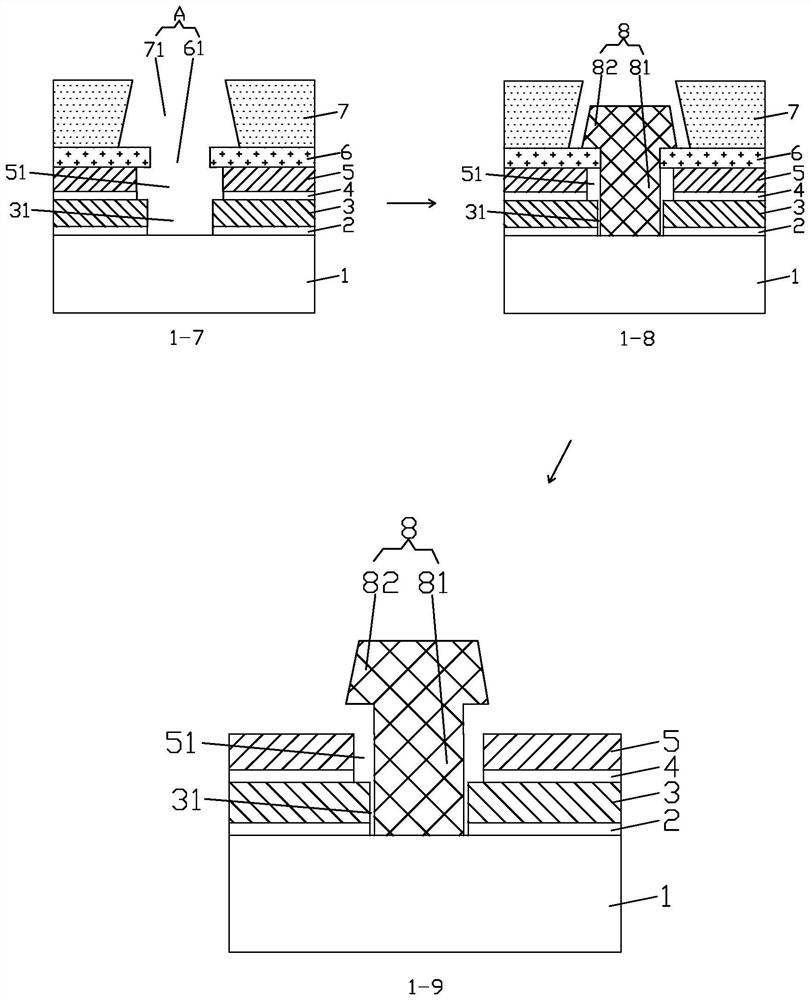

[0034] by figure 1 As an example, a method for fabricating a self-aligned double-groove GaAs field effect transistor of the present invention will be described in detail.

[0035] refer to Picture 1-1 , providing an epitaxial substrate 100 for a field effect transistor, the epitaxial substrate 100 includes an underlying structure 1, a first termination layer 2, an N-type doped GaAs layer 3, a second termination layer 4, and an N-type heavily doped GaAs layer from bottom to top 5. The underlying structure 1 includes known structures such as a substrate, a buffer layer, a channel layer, and a barrier layer, and is formed by using epitaxial materials of conventional GaAs-based field effect transistors. The N-type doped GaAs layer 3 is to increase the device breakdown voltage, and the doping concentration of the N-type doped GaAs layer 3 is 2×10 12 ~5×10 12 cm -3 , the thickness range is less than 15nm. N-type heavily doped GaAs layer 5 is used to make source and drain elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Doping concentration | aaaaa | aaaaa |

| Doping concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com