Preparation technology of mesh plug type patch

A preparation process and patch technology, which is applied in the field of net plug-type patch preparation, can solve the problems of high labor intensity, cumbersome process, high scrap rate, etc., achieve good supporting capacity and filling capacity, simple process, and low labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Step 1. Cutting the petal-shaped polypropylene mesh: Use a laser engraving machine to cut the polypropylene mesh. The cutting speed of the laser engraving machine is 5mm / s-20mm / s, and cut the polypropylene mesh into a petal shape of D8cm Polypropylene mesh4.

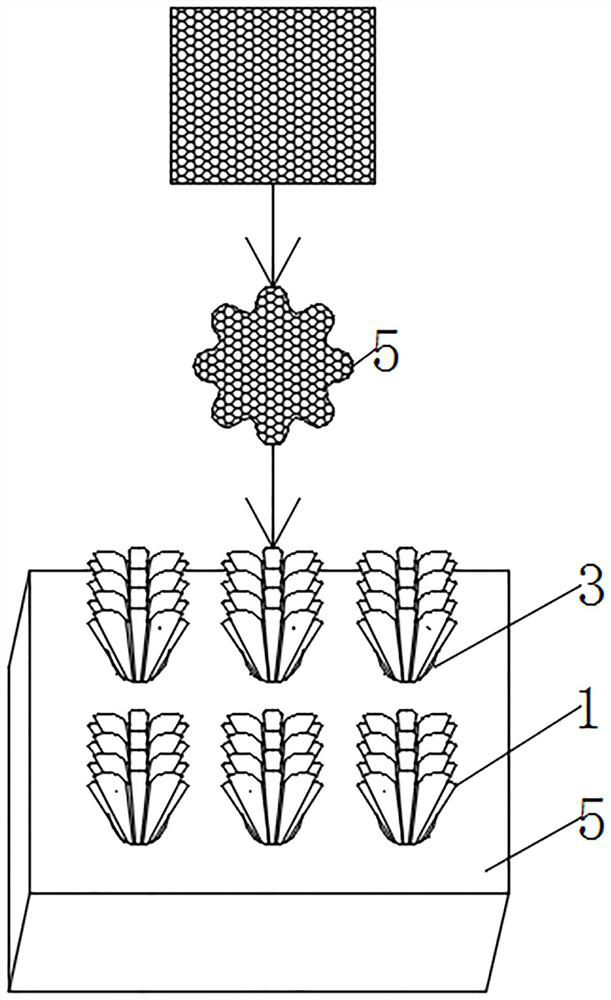

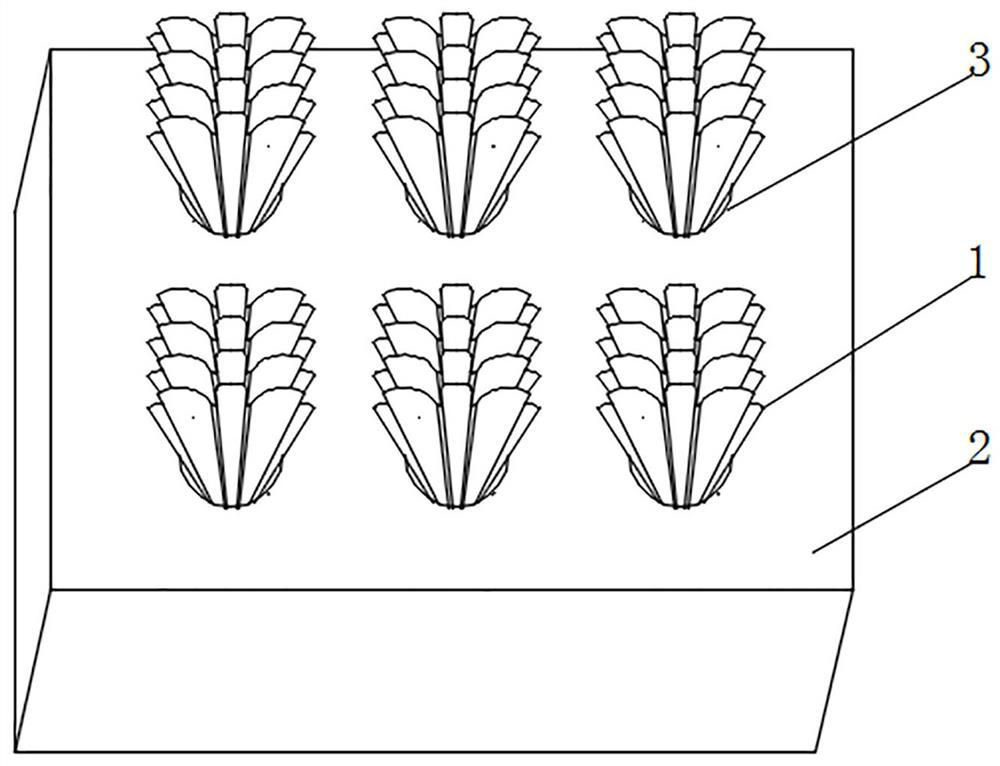

[0048] Step 2, processing the hot-press forming device 5: the hot-press forming device 5 includes a base 2, and several fixing holes 3 are arranged on the base 2; A sizing device 1 is movable; multiple sizing devices 1 are stacked and inserted in the same fixing hole 3 in sequence, and the sizing device 1 is adapted to the petal-shaped polypropylene mesh. Select the sizing device 1 corresponding to the specifications of the petal-shaped polypropylene mesh, if the petal-shaped polypropylene mesh is D8cm, then select the sizing device 1 of D8cm.

[0049]Step 3, heating and shaping: place the petal-shaped polypropylene mesh 4 in the thermoforming device 5, place the first shaping device 1 in the fixing hole 3 of the...

Embodiment 2

[0053] Step 1, cut the petal-shaped polypropylene mesh: use the BCL0406N standard laser engraving machine to cut the polypropylene mesh, the cutting speed of the laser engraving machine is 6mm / s-11mm / s, and cut the polypropylene mesh into D11cm specification Petal-shaped polypropylene mesh 4.

[0054] Step 2, processing thermocompression molding device 5: as figure 2 As shown, the thermoforming device 5 includes a base 2 on which 30 fixing holes 3 are arranged horizontally and 20 fixing holes 3 are arranged vertically, totaling 600 fixing holes. Each fixing hole 3 is provided with 60 sizing devices 1 movably, a total of 3600 sizing devices 1 are stacked and inserted in the 600 fixing holes 3 in sequence, and the sizing devices 1 are compatible with the petal-shaped polypropylene mesh. Select the sizing device 1 corresponding to the specifications of the petal-shaped polypropylene mesh. If the petal-shaped polypropylene mesh is D11cm, select the sizing device 1 of D11cm. The...

Embodiment 3

[0063] Step 1. Cutting the petal-shaped polypropylene mesh: Use a laser engraving machine to cut the polypropylene mesh. The cutting speed of the laser engraving machine is 12mm / s-16mm / s, and cut the polypropylene mesh into a petal shape of D12cm Polypropylene mesh4.

[0064] Step 2, processing thermocompression molding device 5: as figure 2 As shown, the thermoforming device 5 includes a base 2 on which 40 fixing holes 3 are arranged horizontally and 20 fixing holes 3 are arranged vertically, totaling 800 fixing holes. Each fixing hole 3 is provided with 51 sizing devices 1 movably, a total of 4100 sizing devices 1 are stacked and inserted in 800 fixing holes 3 in sequence, and the sizing devices 1 are compatible with the petal-shaped polypropylene mesh. Select the sizing device 1 corresponding to the specifications of the petal-shaped polypropylene mesh. If the petal-shaped polypropylene mesh is D12cm, then select the sizing device 1 of D12cm.

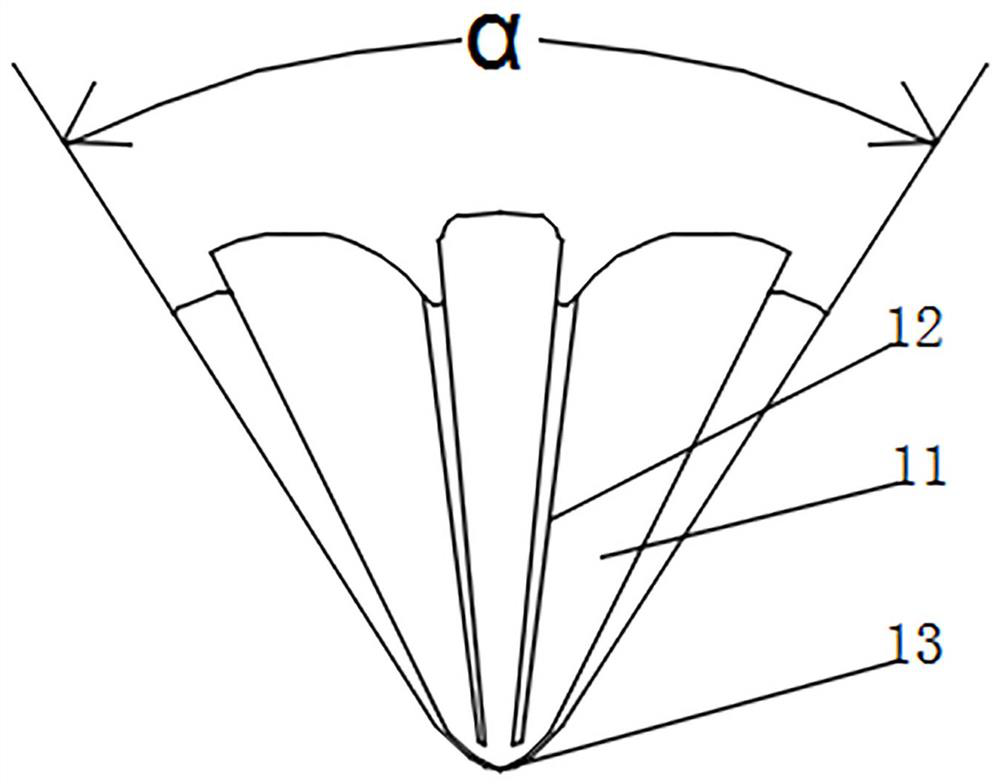

[0065] The angle α between...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com