Carbon nanotube phthalocyanine nano composite material and preparation method and application thereof

A technology of nanocomposite materials and carbon nanotubes, applied in the direction of carbon compounds, chemical instruments and methods, fibrous fillers, etc., can solve the problems of poor solubility and limited application of phthalocyanine, achieve good dispersion stability, improve rapid transfer, The effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Take 1 g of multi-walled carbon nanotubes and disperse them in 150 mL of concentrated nitric acid. After ultrasonication for 15 minutes, heat the mixture to 100°C-120°C for 8 hours. Wash with ionized water until neutral, and dry in vacuum at 70° C. for 24 hours to obtain 900 mg of carboxylated carbon nanotubes.

Embodiment 2

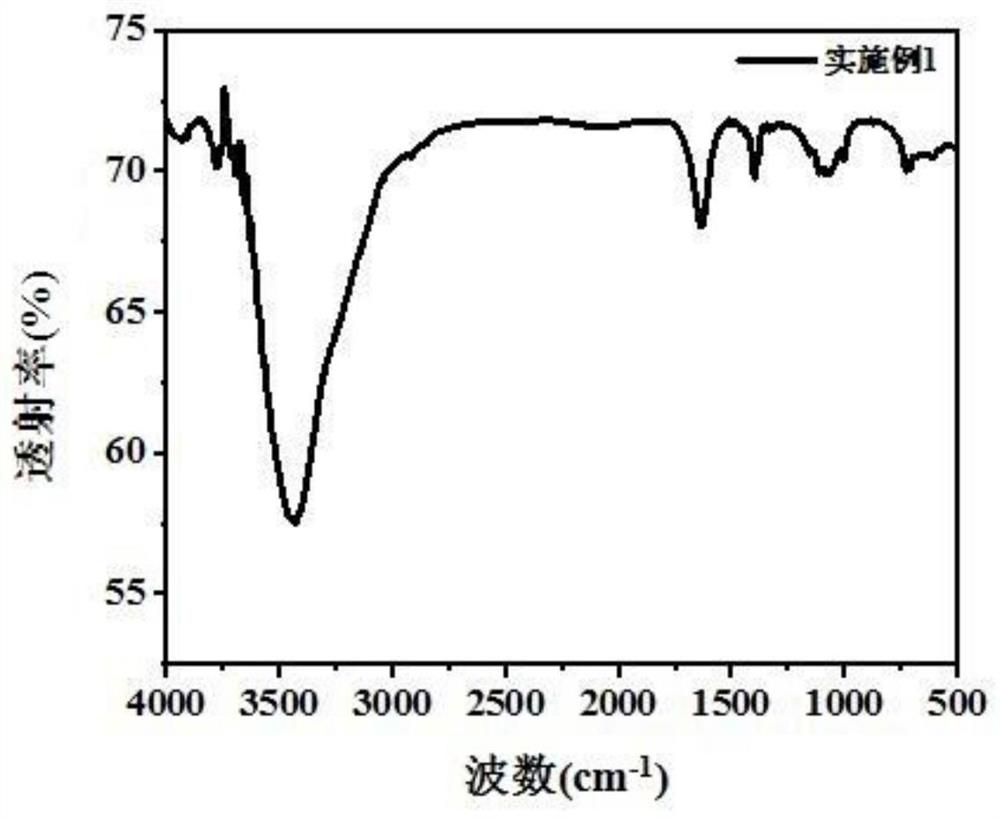

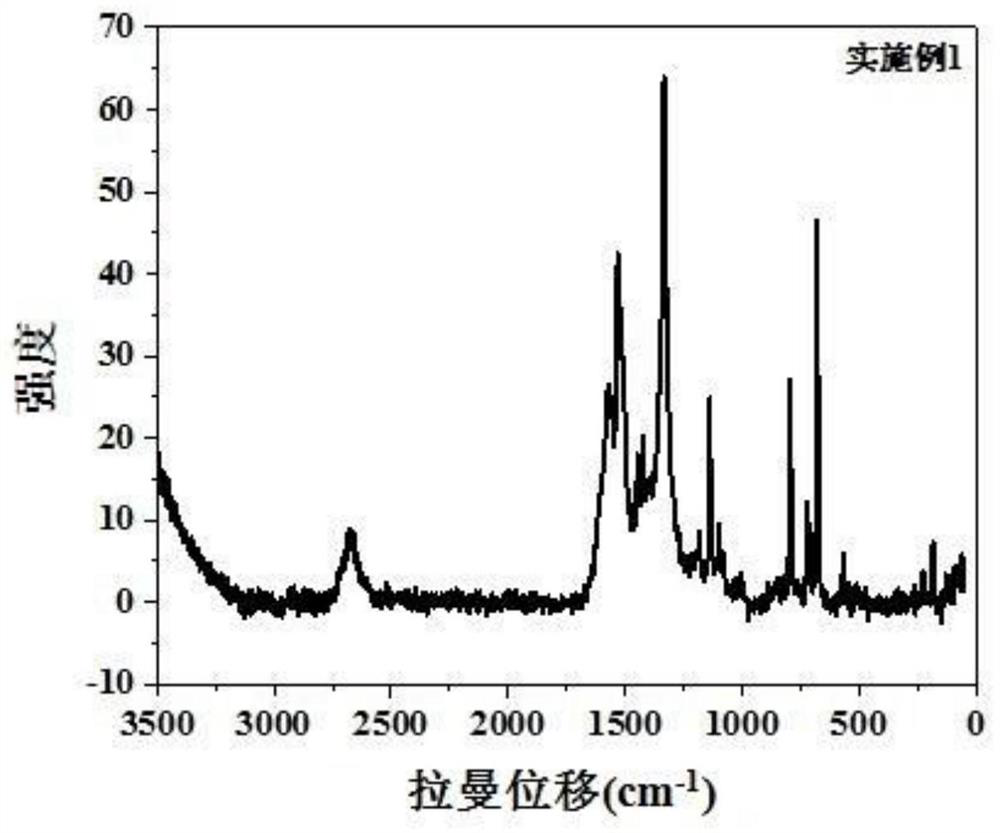

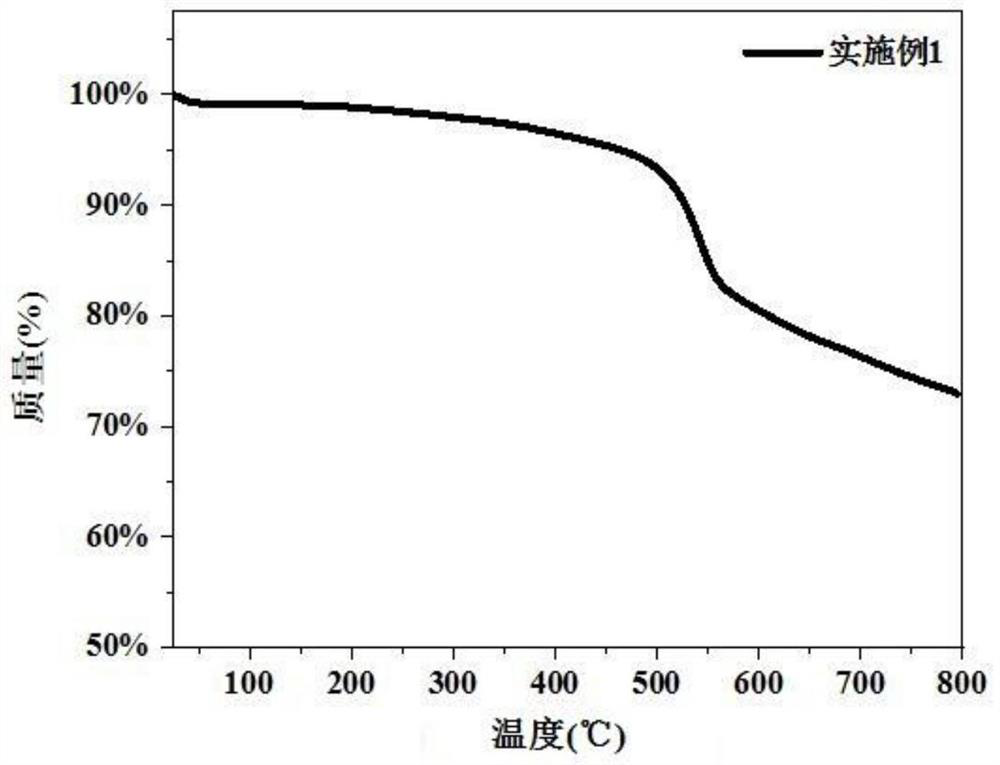

[0040] Dissolve 500 mg of metal-free phthalocyanine in 100 mL of concentrated sulfuric acid, add 100 mL of deionized water after the dissolution is complete, add 300 mg of carboxylated carbon nanotubes under stirring, heat the above mixture to 60°C for 24 hours, and cool to room temperature after the reaction. Filter with a 0.22 μm filter membrane, wash the product with deionized water until neutral, and dry it in vacuum at 70°C for 24 hours to obtain 400 mg of carbon nanotube phthalocyanine nanocomposite material I. Carry out infrared test to the carbon nanotube phthalocyanine nanocomposite material I that embodiment 2 prepares, test result is as follows figure 1 . 3440cm -1 The nearby peak with stronger intensity is the stretching vibration peak of the carboxyl O-H bond of carbon nanotubes; 1638cm -1 The nearby peak is the carbonyl characteristic peak of carboxyl; 1404cm -1 The nearby peaks are characteristic peaks of C-N bonds, indicating that nitrogen has been introduce...

Embodiment 3

[0042] Take 500 mg of carboxylated carbon nanotubes and disperse 500 mg of carboxylated carbon nanotubes in 30 mL of thionyl chloride, seal the tube and heat to 70 ° C for 24 hours. The product is washed with dichloromethane to remove excess thionyl chloride, and vacuum-dried to obtain the acid chloride product . Disperse the above acyl chloride carbon nanotubes in 200 mL of dichloromethane, add 5 g of polyetheramine D2000, react at room temperature for 24 hours, filter the product, wash off excess polyetheramine with dichloromethane, and vacuum dry to obtain aminated carbon nanotubes; Dissolve 600 mg of metal-free phthalocyanine in 100 mL of concentrated sulfuric acid, add 400 mL of deionized water after the dissolution is complete, add 360 mg of aminated carbon nanotubes under stirring, heat the above mixture to 60°C for 24 hours, and cool to room temperature after the reaction , filtered through a 0.22 μm filter membrane, the product was washed with deionized water until ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com