Nitrogen-doped carbon polymer/TiO2 photoelectrode, as well as preparation method and application thereof

A nitrogen-doped carbon and polymer technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of difficult recycling and low catalytic efficiency, and achieve convenient operation and light response Wide range and the effect of overcoming the difficulty of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Pretreatment of titanium sheets: Ultrasonic cleaning of titanium sheets (length×width×thickness=100mm×15mm×0.16mm) in acetone, isopropanol and methanol for 15 minutes respectively, and finally dried at 80°C to obtain clean Titanium sheet.

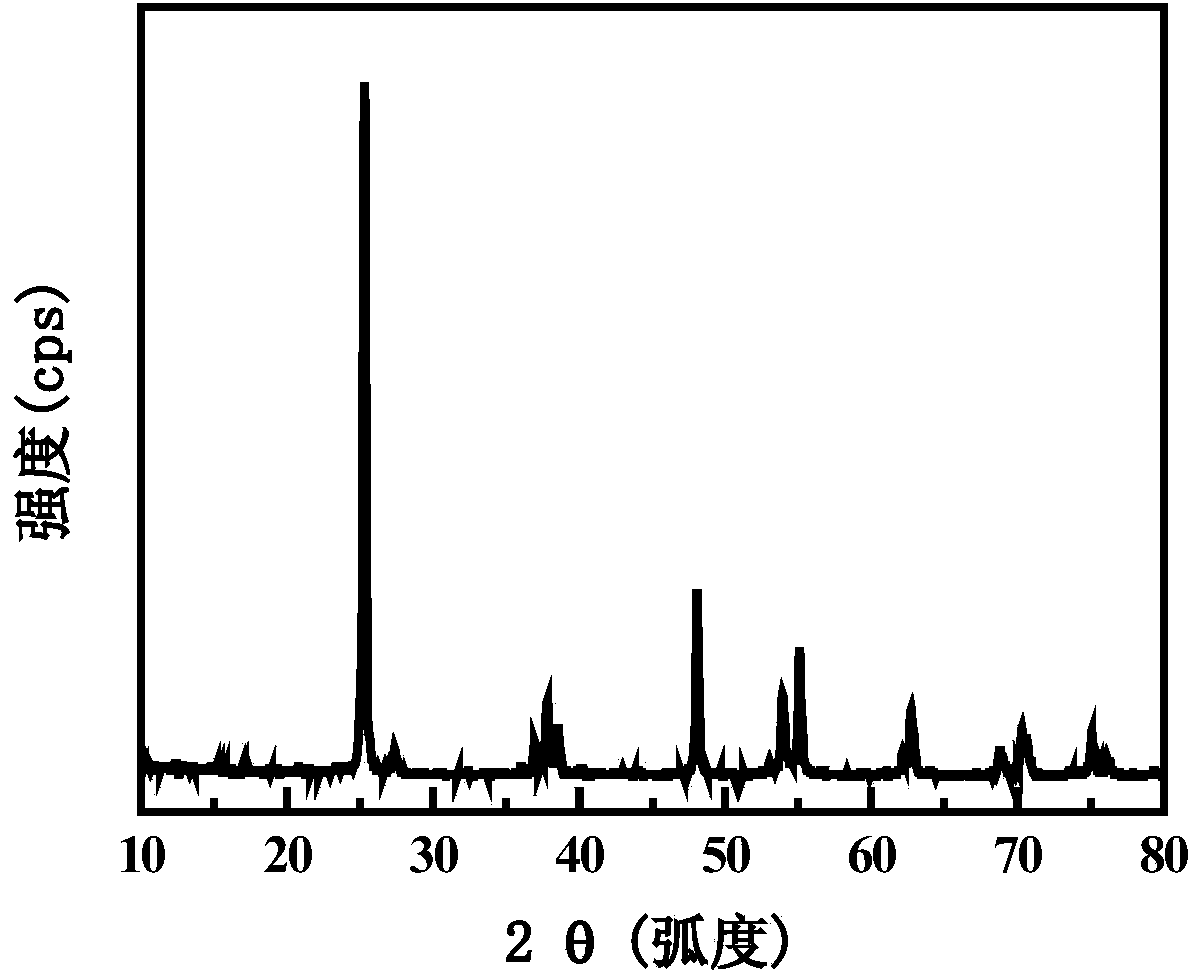

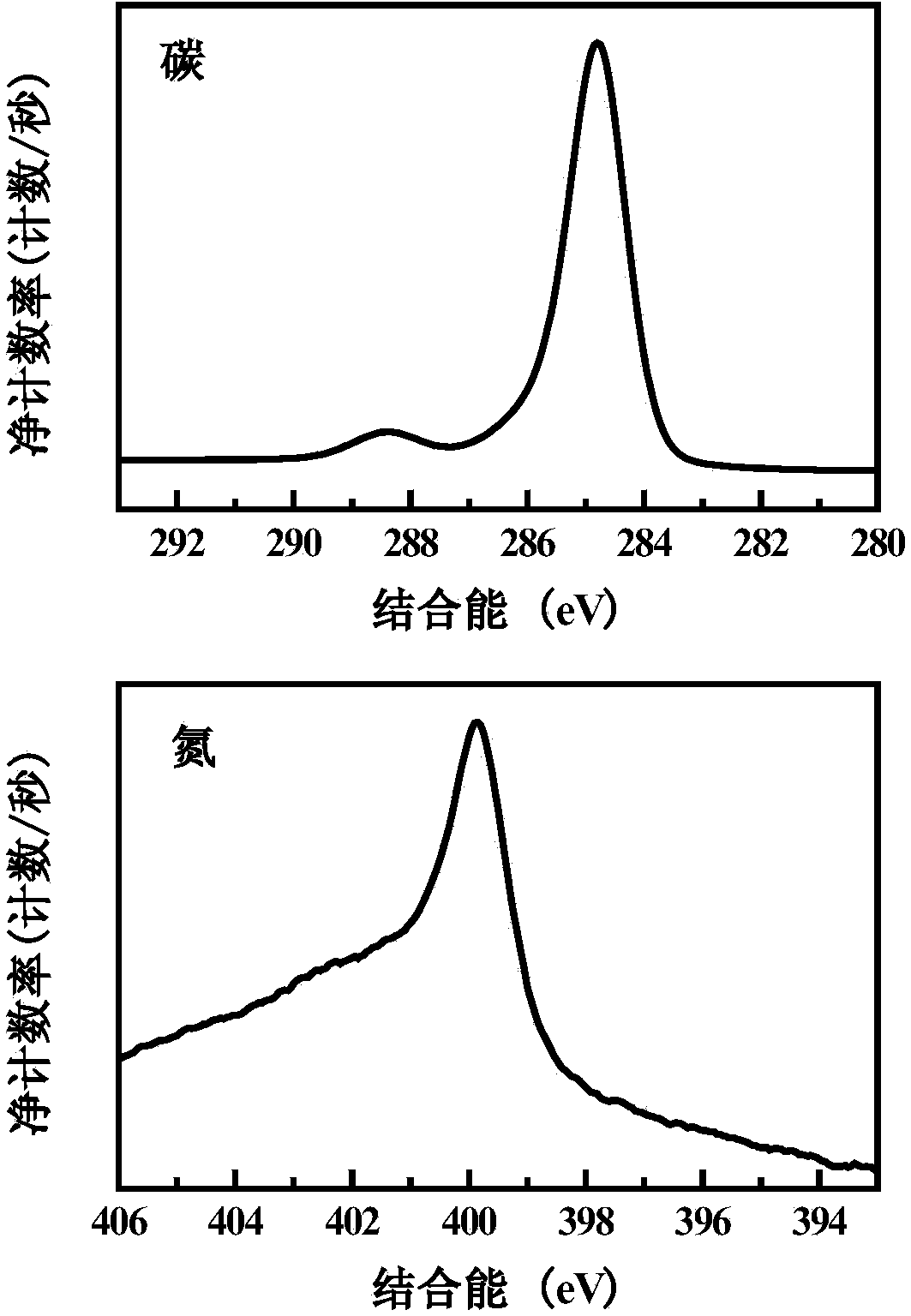

[0038] (2) Electrode preparation: add 1.0g melamine and 1.0g NH to 40mL deionized water 4 F. Ultrasound the mixed system for 30 minutes to obtain a milky white suspension mixed system, then transfer it to a 70mL autoclave, and add a clean titanium sheet. After sealing it, it is hydrothermally reacted at 150°C for 72h. The reacted titanium sheet is deionized with 100mL Rinse with water and dry at 80°C for 2h, then put into a crucible, heat up to 550°C at a rate of 20°C / min and keep for 4h, then cool down to room temperature naturally to obtain a photoelectrode. figure 1 The given scanning electron microscope pictures show that the obtained electrode surface is composed of rough micron blocks, and these blocks are interlaced. pas...

Embodiment 2

[0041] (1) Pretreatment of titanium sheet: same as in Example 1, the only difference is that the size of the selected titanium sheet is length×width×thickness=10mm×10mm×0.05mm.

[0042] (2) Electrode preparation: add 2.0g melamine and 1.0g NH to 40mL deionized water 4 F. Ultrasound the mixed system for 30 minutes to obtain a milky white suspension mixed system, then transfer it to a 70mL autoclave, and add a clean titanium sheet, seal it and perform a hydrothermal reaction at 120°C for 72h, and remove the reacted titanium sheet with 100mL. Rinse with deionized water and dry at 50°C for 2h, then put into a crucible, heat up to 450°C at a rate of 20°C / min and keep for 4h, then cool naturally to room temperature to obtain a photoelectrode.

[0043] (3) Characterization of electrode activity: same as Example 1. The experimental results show that 107 cfu / ml of E. coli k-12 can be inactivated by 7-log after 30 minutes of light irradiation.

Embodiment 3

[0045] (1) Pretreatment of titanium sheet: same as in Example 1, the only difference is that the size of the selected titanium sheet is length×width×thickness=50mm×10mm×0.3mm.

[0046] (2) Electrode preparation: add 1.5g melamine and 1.0g NH to 40mL deionized water 4 F. Ultrasound the mixed system for 30 minutes to obtain a milky white suspension mixed system, then transfer it to a 70mL autoclave, and add a clean titanium sheet, seal it and perform a hydrothermal reaction at 180°C for 72h, and remove the reacted titanium sheet with 100mL Rinse with deionized water and dry at 150°C for 2h, then put into a crucible, heat up to 550°C at a rate of 20°C / min and keep for 2h, then cool down to room temperature naturally to obtain a photoelectrode.

[0047] (3) Characterization of electrode activity: same as Example 1. The experimental results show that 107 cfu / ml of E. coli k-12 can be inactivated by 7-log after 50 minutes of light irradiation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com