NiCo<2>O<4>(at)Ni-B negative electrode material for lithium battery and preparation method thereof

A negative electrode material, lithium battery technology, applied in battery electrodes, nanotechnology for materials and surface science, secondary batteries, etc., can solve volume change, low conductivity and other problems, and achieve improved specific capacity and good rate capability , the effect of good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

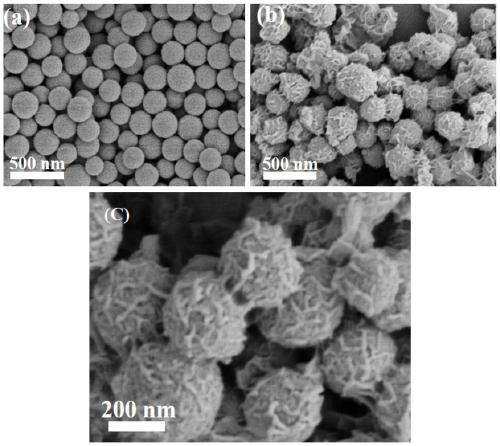

[0029] Example 1: NiCo 2 o 4 material preparation

[0030] A NiCo 2 o 4 As the preparation method of lithium ion battery negative electrode material, comprise the steps:

[0031] Step (1), dissolving polyvinylpyrrolidone and 8mL glycerin in 40mL isopropanol solution, stirring and dissolving evenly at a rate of 250r / min on a magnetic stirrer, to obtain a transparent polyvinylpyrrolidone mass fraction of 0.8%-0.9%. pink solution;

[0032] Step (2), adding nickel nitrate hexahydrate and cobalt nitrate hexahydrate to the resulting mixed solution, continuing to stir on a magnetic stirrer until dissolving to obtain a homogeneous solution, wherein the mass fraction of nickel nitrate hexahydrate is 0.3%-0.4%, The mass fraction of cobalt nitrate hexahydrate is 1.0%-2.0%;

[0033] In step (3), the obtained homogeneous solution is transferred to a reaction kettle, sealed at 180° C. for 6 hours, and the obtained product is centrifuged with absolute ethanol and then dried to collect ...

Embodiment 2

[0035] Example 2: NiCo 2 o 4 Preparation of @Ni-B anode material

[0036] A kind of NiCo 2 o 4 A method for preparing @Ni-B as a lithium-ion battery negative electrode material, including the following steps:

[0037] Step (1), the NiCo that above-mentioned embodiment 1 obtains 2 o 4 The material and nickel nitrate hexahydrate were dissolved in 100mL deionized water, stirred and dissolved evenly at a rate of 500r / min on a magnetic stirrer, and a mixed salt solution was obtained;

[0038]In step (2), the obtained mixed salt solution is degassed under an argon atmosphere for 0.5 h, and then an aqueous sodium borohydride solution with a mass fraction of 0.2%-0.3% is added, and the obtained product is stirred and centrifuged;

[0039] Step (3), the obtained product is freeze-dried overnight in a vacuum oven to obtain NiCo 2 o 4 @Ni-B Composite.

[0040] Among them, NiCo 2 o 4 The mass ratio of the material to nickel nitrate hexahydrate is 1:3.

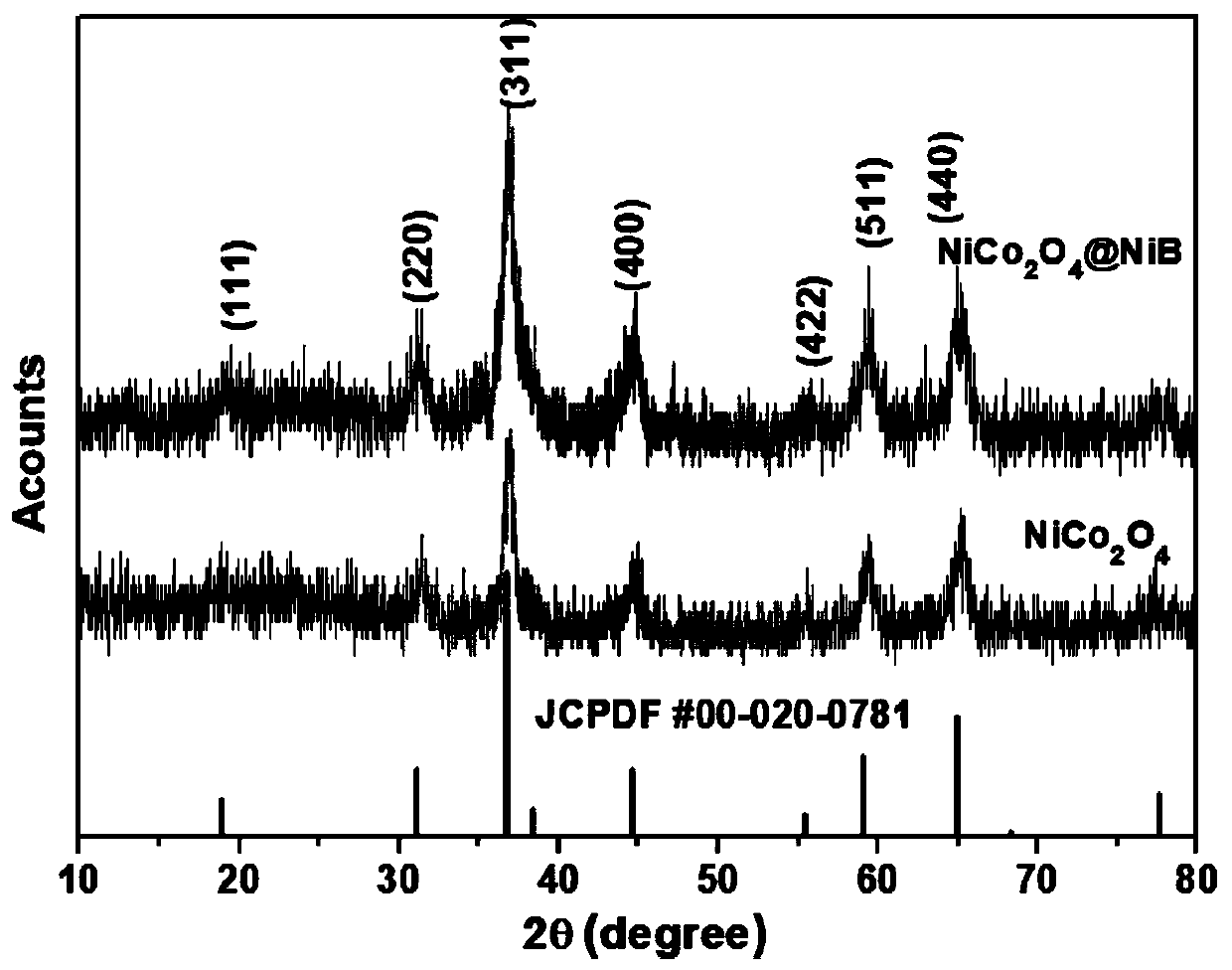

[0041] The material obt...

Embodiment 3

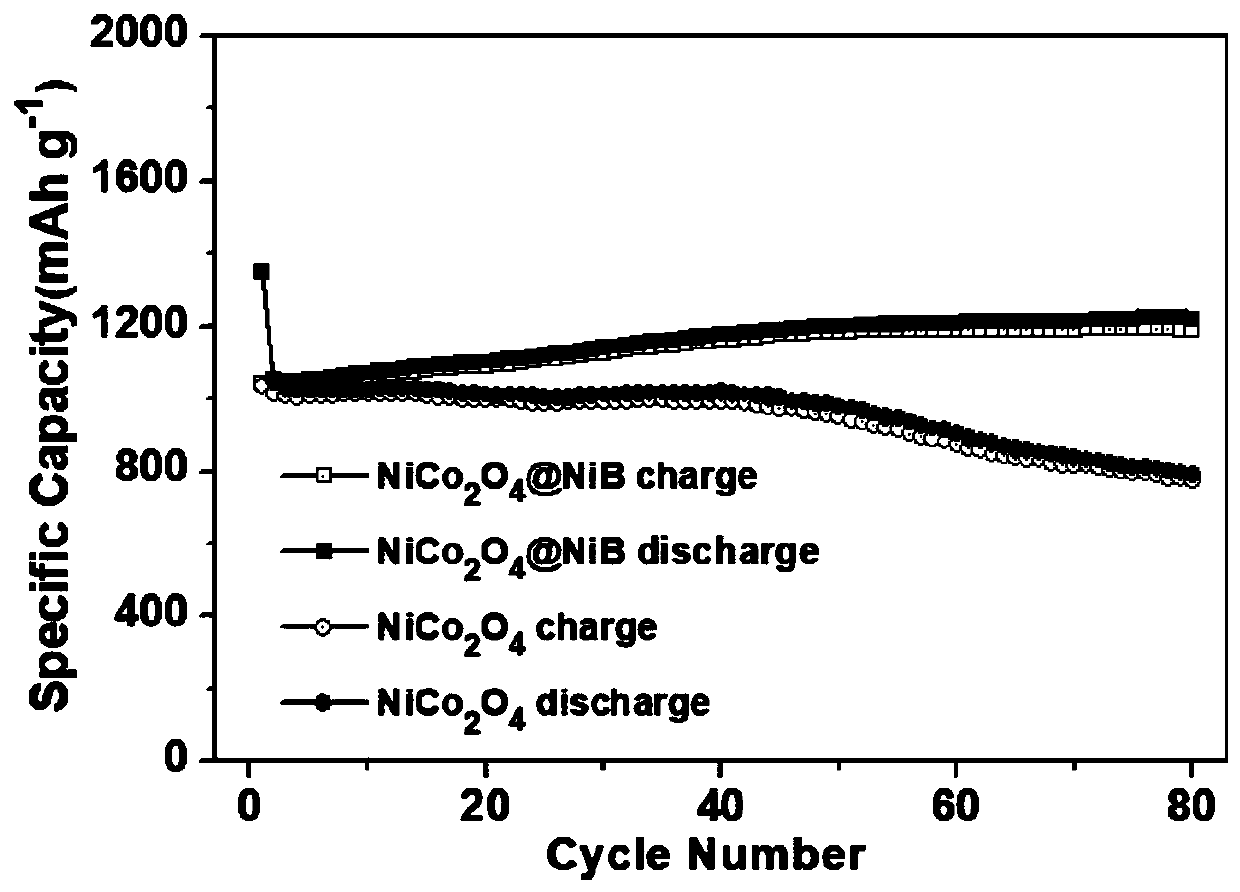

[0042] Embodiment 3: performance measurement

[0043] The materials obtained in the above-mentioned Example 1 and Example 2 were subjected to a battery performance test, and the specific steps were as follows:

[0044] NiCo 2 o 4 or NiCo 2 o 4 @Ni-B powder is the active material, carbon black (Super P) is the conductive agent, sodium carboxymethylcellulose (CMC) is the binder, the mass ratio of the three is 7:2:1, add deionized water and a small amount Ethanol was ball-milled on a ball mill for 2 hours to make a uniform slurry, which was coated on an aluminum foil current collector to make a pole piece of the battery. Lithium sheet as the negative electrode, polyethylene diaphragm, using 1M LiPF 6 / EC+EMC (volume ratio 1:1) is the electrolyte, and it is assembled into a button-type battery in a glove box filled with argon. Tested at 0.2A·g -1 Under the current density, after 80 cycles, NiCo 2 o 4 Discharge specific capacity maintains 709mAh·g -1 ,NiCo 2 o 4 @Ni-B e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Reversible capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com