Titanium-based alloy powder and preparation method thereof, and preparation method of titanium-based alloy parts

A technology of titanium-based alloy and powder, which is applied in the field of metal materials and its preparation, can solve the problems of insufficient fluidity and high cost of titanium-based alloy powder, and achieve the effects of short preparation cycle, strong repeatability and simple process method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] At the same time, the invention also discloses a method for preparing interstitial atom-strengthened titanium-based alloy powder, which specifically includes the following steps:

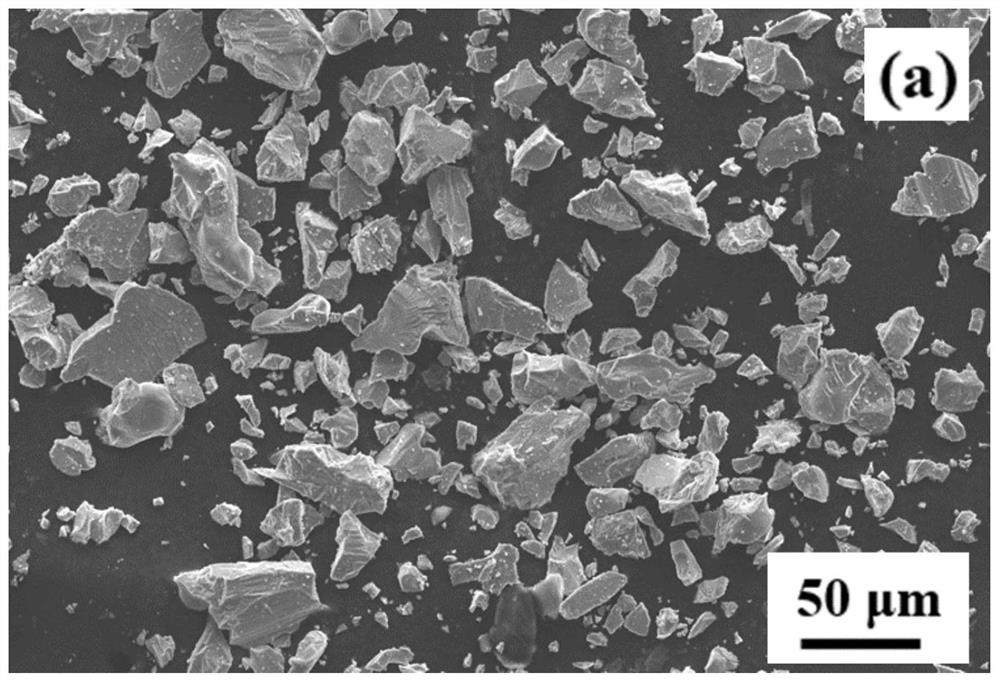

[0046] S100: Weigh non-spherical hydrogenated dehydrogenation titanium powder and grinding balls, and put them into a rotary tube furnace, and the tube furnace rotates at a speed of 10~60rad / min. Among them: the particle size of hydrogenated dehydrogenated titanium powder is -325 mesh; the mass ratio of grinding balls to hydrogenated dehydrogenated titanium powder is 0.5~2:1.

[0047] S200: Introduce a mixture of argon gas and gas containing interstitial atoms into the above-mentioned rotary tube furnace, raise the temperature of the tube furnace to 140-200°C at a heating rate of 5-10°C / min, and keep it warm for 30min-3h, so that the gap Atoms fully and uniformly react with the non-spherical hydrodehydrogenated titanium-based alloy powder.

[0048] S300: Introduce argon gas into the above-me...

Embodiment 1

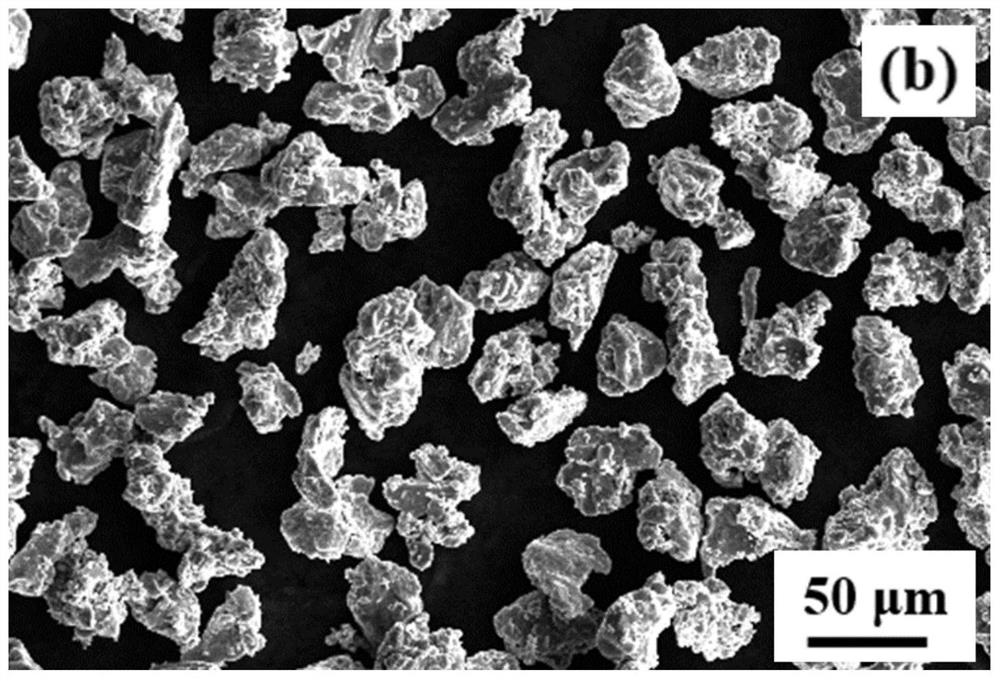

[0060] The hydrogenated dehydrogenated titanium powder is used as the raw material, and the particle size of the hydrogenated dehydrogenated titanium powder is -325 mesh. Put titanium powder and zirconia grinding balls into a tubular quartz boat with a mass ratio of 1:1, put them into a rotary sintering furnace, raise the temperature to 160°C at 5°C / min, and keep it warm for 30min. The whole process is under argon and oxygen (oxygen volume fraction 10vol%) in a mixed atmosphere. After the heat preservation is over, replace the atmosphere with a pure argon protective atmosphere, raise the temperature to 450°C at a rate of 5°C / min, and hold the temperature for 60 minutes to promote the full solid solution of O in the powder. At the same time, under the combined action of mechanical force and high temperature, hydrogenation The irregular shape of the dehydrogenation powder is spheroidized, the particle size is uniform, and the alloyed titanium-based alloy powder is obtained after...

Embodiment 2

[0063] The hydrogenated dehydrogenated titanium powder is used as the raw material, and the particle size of the hydrogenated dehydrogenated titanium powder is -325 mesh. Put titanium powder and zirconia grinding balls into a tubular quartz boat with a mass ratio of 0.5:1, put them into a rotary sintering furnace, raise the temperature to 200°C at 10°C / min, and keep it warm for 3 hours. The whole process is under argon and nitrogen (Nitrogen gas fraction 10vol%) in a mixed atmosphere. After the heat preservation is over, replace the atmosphere with a pure argon protective atmosphere, raise the temperature to 600°C at a rate of 10°C / min, and hold the heat for 3 hours to promote the full solid solution of N in the powder. At the same time, under the combined action of mechanical force and high temperature, hydrogenation The irregular shape of the dehydrogenation powder is spheroidized, the particle size is uniform, and the alloyed titanium-based alloy powder is obtained after co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com