Variable-frequency signal injection embedded permanent magnet synchronous motor maximum torque current ratio control method

A technology of maximum torque current, permanent magnet synchronous motor, applied in the field of maximum torque to current ratio control of multi-phase motors, can solve problems such as interference, signal frequency limitation, occupying large storage space, etc., to achieve the effect of simplifying the system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

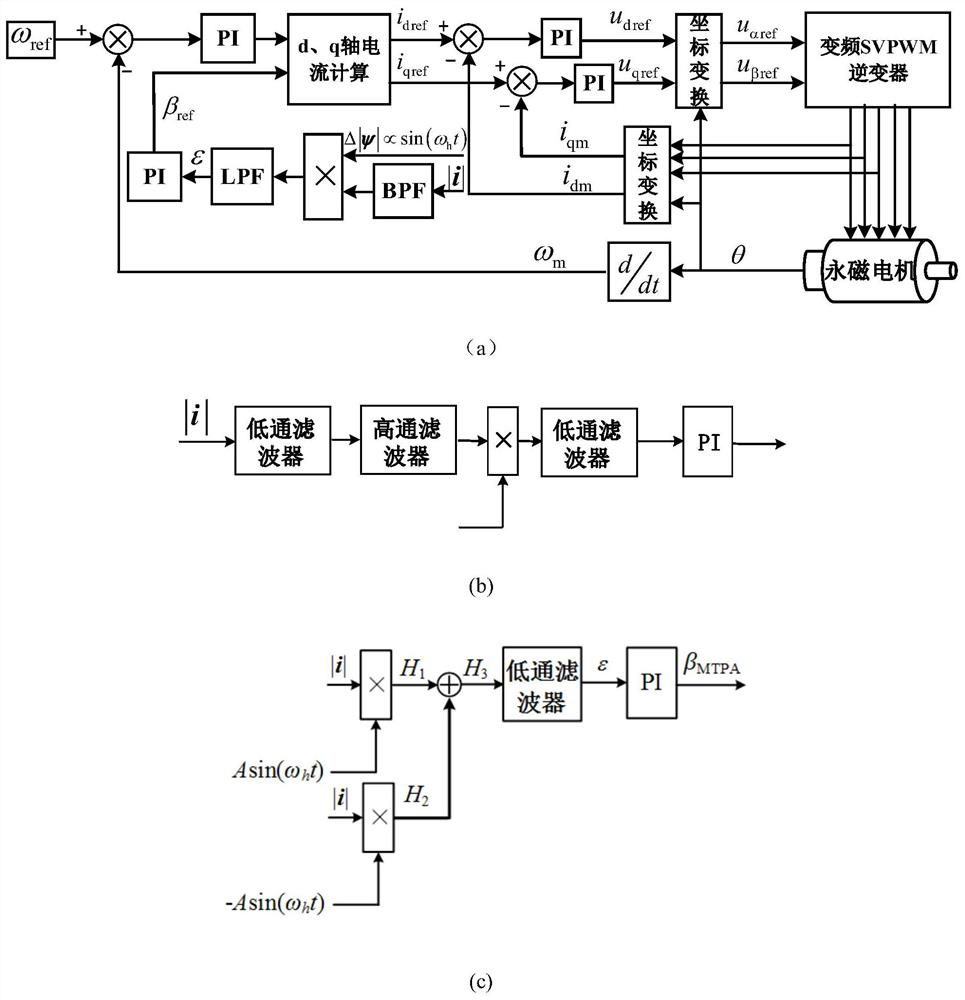

[0047] A method for controlling the maximum torque-to-current ratio of an embedded permanent magnet synchronous motor with variable frequency signal injection, comprising the following steps:

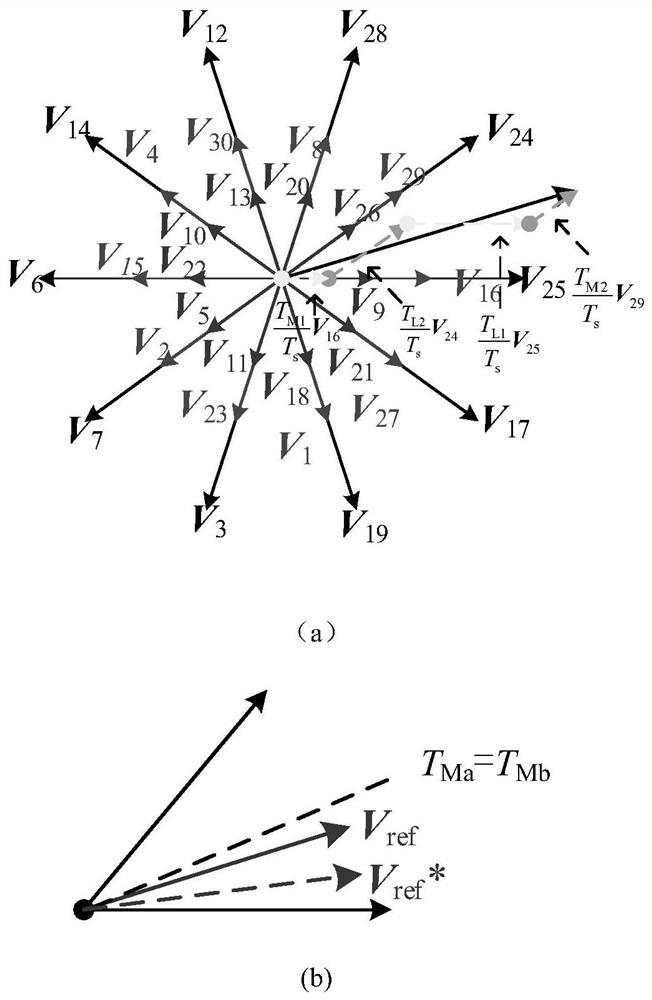

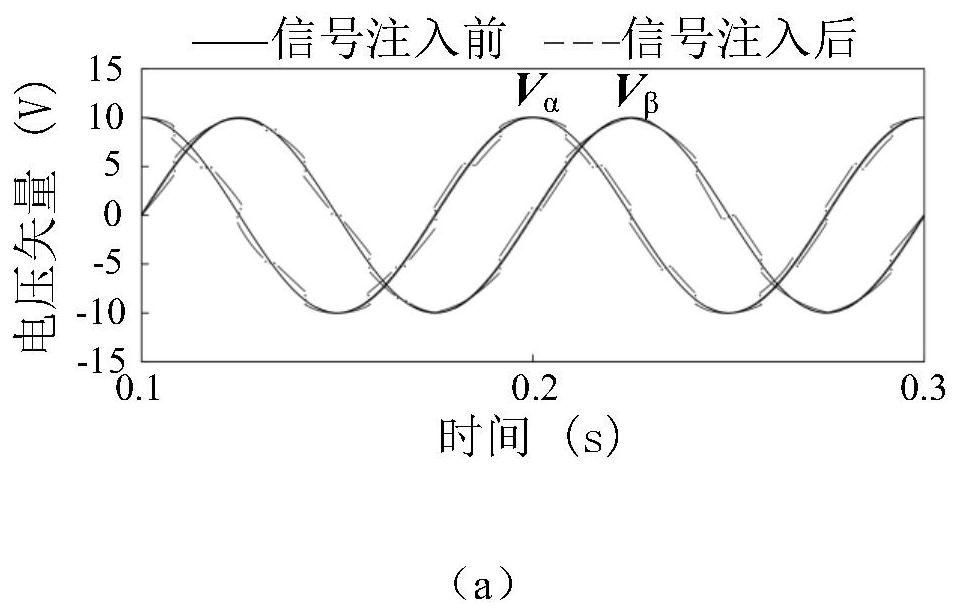

[0048] Step 1, when the reference voltage vector enters the space vector pulse width modulation algorithm to start vector synthesis, first judge the speed, adjust the action time of different vectors at different speeds, and generate the fundamental frequency of the motor in one electrical cycle a disturbance signal, which is injected directly into the motor;

[0049] Step 2, judge the sector, and adjust the vector action time of different sectors at different speeds. When the motor speed is less than 800r / min, it is necessary to adjust the two adjacent vectors in each of the ten sector...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com