Manufacturing method of oil supplementing pump rotor based on powder metallurgy

A powder metallurgy and manufacturing method technology, applied in other manufacturing equipment/tools, engine components, mechanical equipment, etc., can solve the problems of easy damage to the inner and outer rotors, large heat treatment deformation, rapid speed changes, etc., to ensure consistency and improve hardness and accuracy, the effect of meeting the life expectancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0050] Based on the manufacturing method of the powder metallurgy charging pump rotor, the specific steps are as follows:

[0051] 1. Modulate the rotor material composition

[0052] 1.1) Modulate the material composition of the inner rotor

[0053] Based on the speed of the charge pump, the rated working pressure and the material requirements of the working conditions, the mass fraction of the inner rotor material is: C is 0.3-0.5%, Ni is 0.6-2.0%, Cu is 1.0-3.0%, and the rest is Fe;

[0054] 1.2) Modulate the material composition of the outer rotor

[0055] The mass fraction of the material composition of the outer rotor is: C is 0.25-0.5%, Ni is 0.6-1.5%, Mo is 0.2-0.4%, Cu is 0.6-2%, and the rest is Fe;

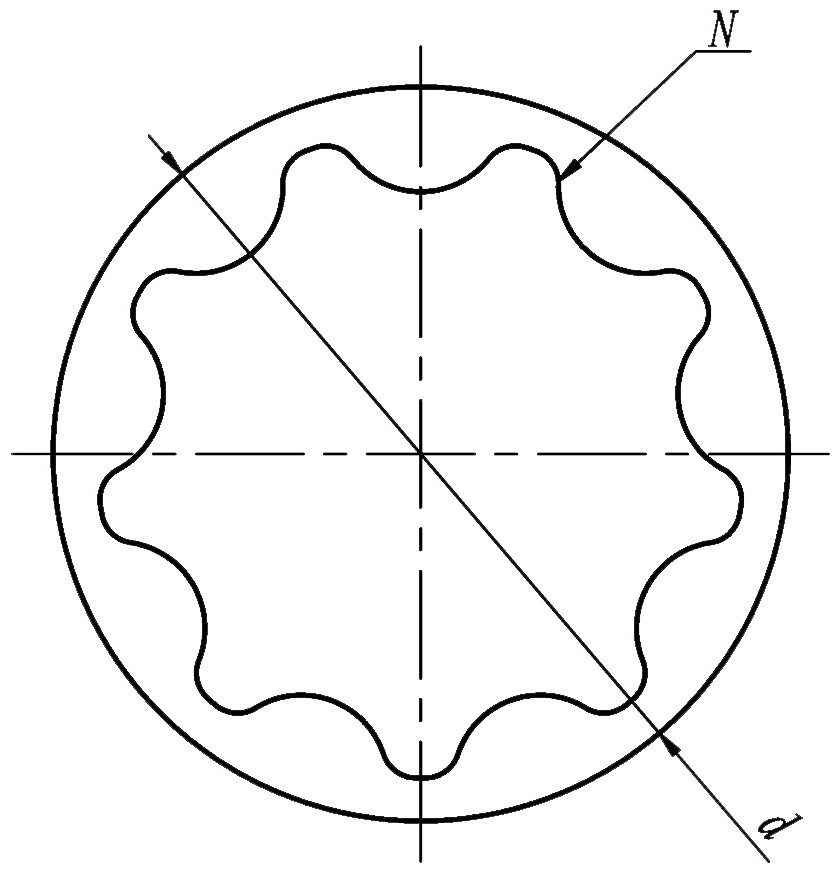

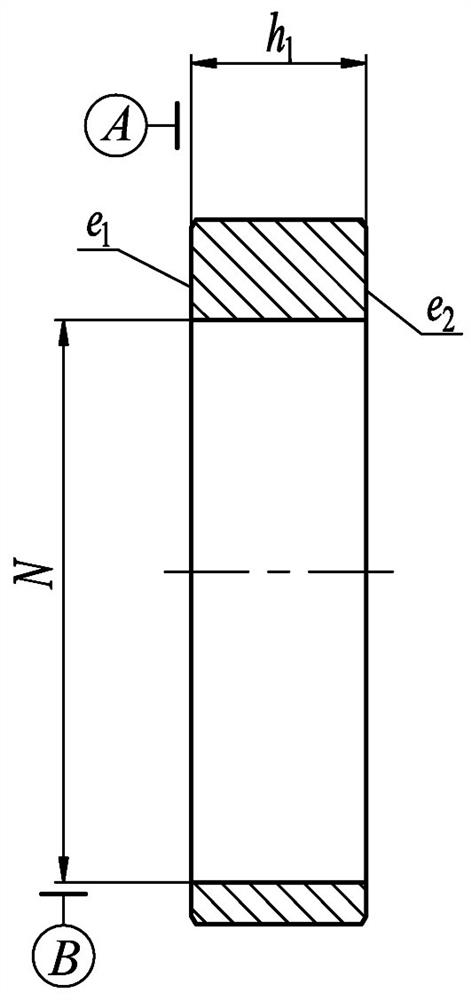

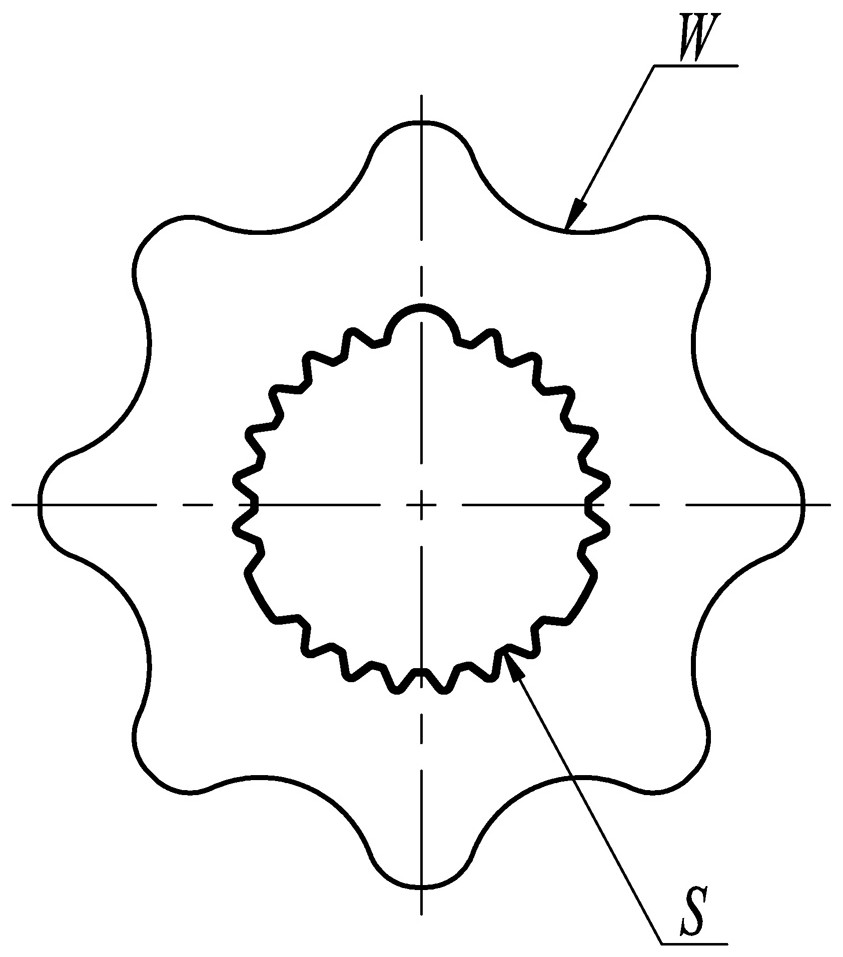

[0056] 2. Design the rotor struct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| verticality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com