Cathode tool for machining reducing round hole in conductor material and machining method

A technology of conductor materials and cathodes, applied in the supply of processing working media, manufacturing tools, metal processing equipment, etc., can solve the problems of poor hole wall surface quality and processing difficulties, and achieve simple structure, high surface quality, and easy processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1, see figure 2 A method for processing a circular hole in a conductor material using the above-mentioned cathode tool, comprising the following steps:

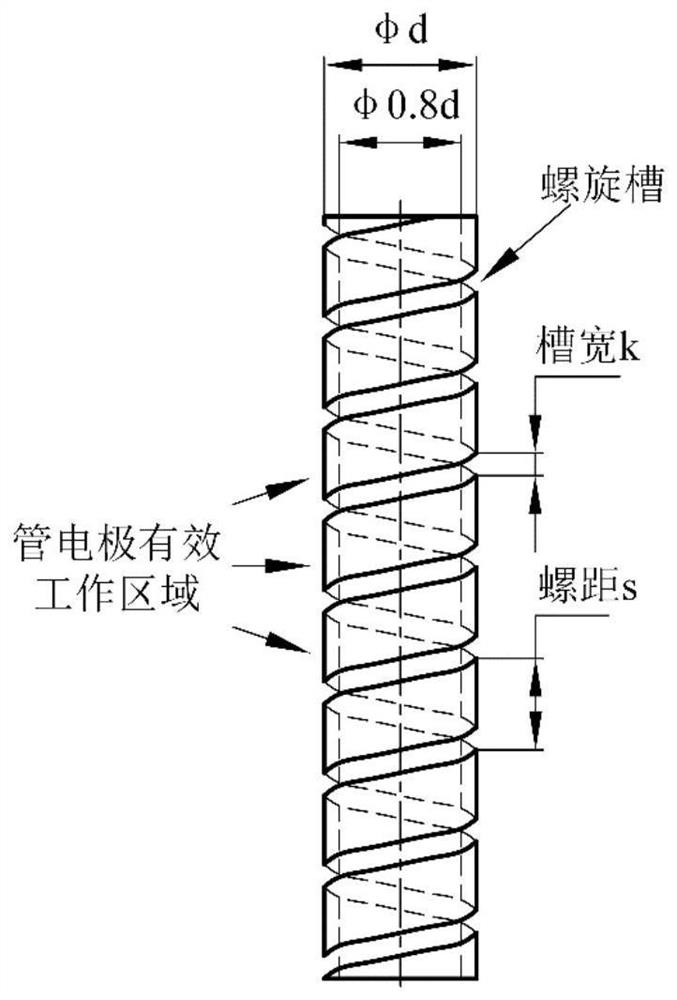

[0029] 1. The outer diameter of the tube electrode is d, and the inner diameter of the tube electrode is 0.8d. On the surface of the tube electrode, a spiral groove is processed. The pitch of the spiral groove is s, and the groove width is k. In this embodiment, the spiral groove on the cathode tool The pitch s and slot width k are the same;

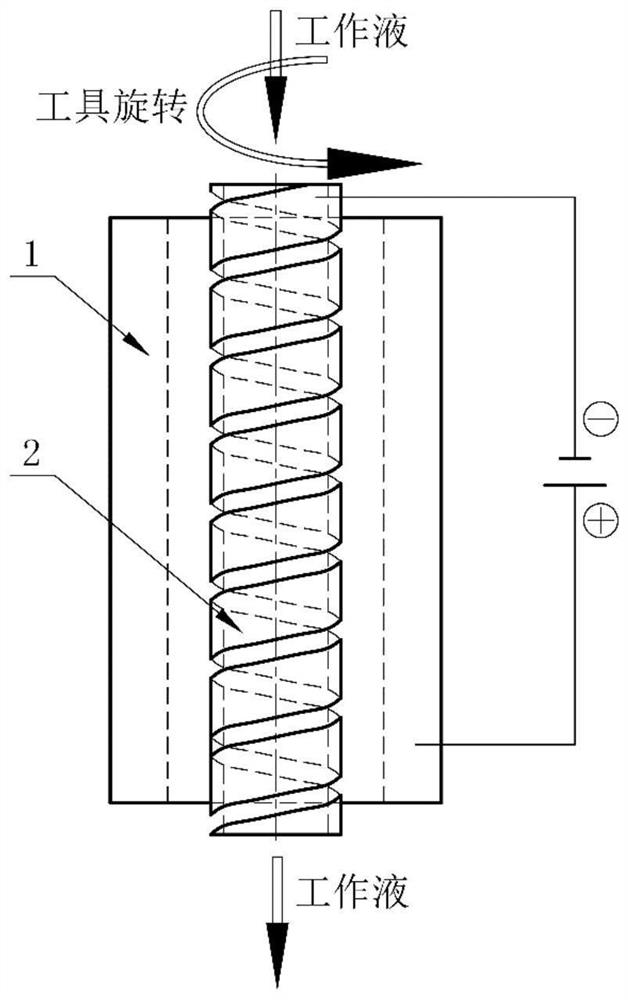

[0030] 2. The conductor workpiece processed with a cylindrical hole with an inner diameter of D is fixed in the machine tool workbench. The height of the selected tube electrode is greater than the height of the cylindrical hole. Under the action of the machine tool fixture, the cathode tool is placed in the cylindrical hole of the conductor workpiece. middle;

[0031] 3. The voltage of the DC power supply is 10V-20V, the tube electrode is connected to the cathode of t...

Embodiment 2

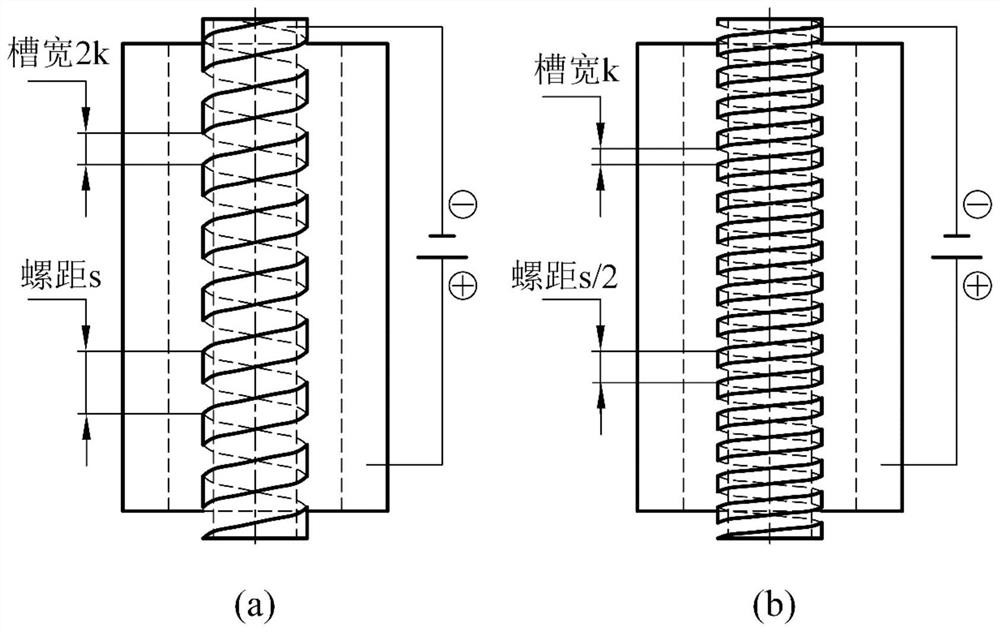

[0033] Embodiment 2, described method is the same as embodiment 1, and difference is that increased groove width k, as image 3 As shown in (a); or reduce the pitch s, such as image 3 As shown in (b), the effective working area of the tube electrode can be reduced. If the effective working area of the tube electrode is reduced, the material removed from the workpiece will be reduced under the same conditions, so when such a tube electrode is used to process a cylindrical hole, the obtained hole diameter will also be reduced.

Embodiment 3

[0034] Embodiment 3, reducing the groove width of the helical groove or increasing the pitch of the helical groove can increase the effective working area of the tube electrode. When the effective working area of the tube electrode increases, the material removed from the workpiece will also increase under the same conditions, so when such a tube electrode is used to process a cylindrical hole, the obtained hole diameter will also become larger.

[0035] Through Examples 2 and 3, it can be found that if the aperture to be processed is larger, a spiral groove with a large pitch and a small groove width can be processed on the surface of the tube electrode; on the contrary, if the aperture to be processed is smaller, it can be processed in The surface of the tube electrode adopts a spiral groove with a small pitch and a large groove width. Therefore, by changing the pitch s and groove width k of the spiral groove, the effective working area of the tube electrode can be cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com