Device for producing ammonium sulfate from dye sulfuric acid wastewater

A technology of ammonium sulfate and ammonium sulfate solution, applied in the direction of ammonia compounds, inorganic chemistry, chemical instruments and methods, etc., can solve the problems of easy clogging of precision filters, difficulty in evaporation, concentration and crystallization, etc., to improve processing efficiency and excellent indicators , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

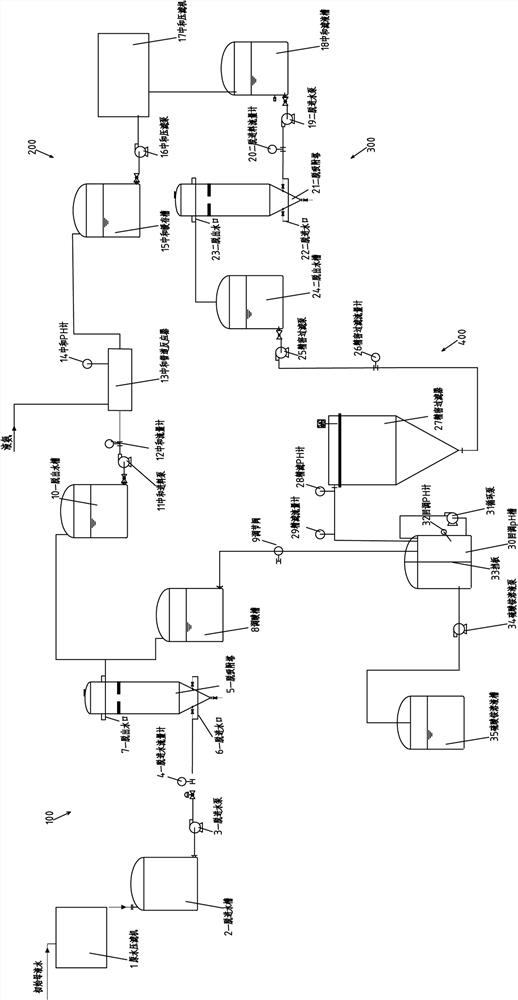

[0021] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

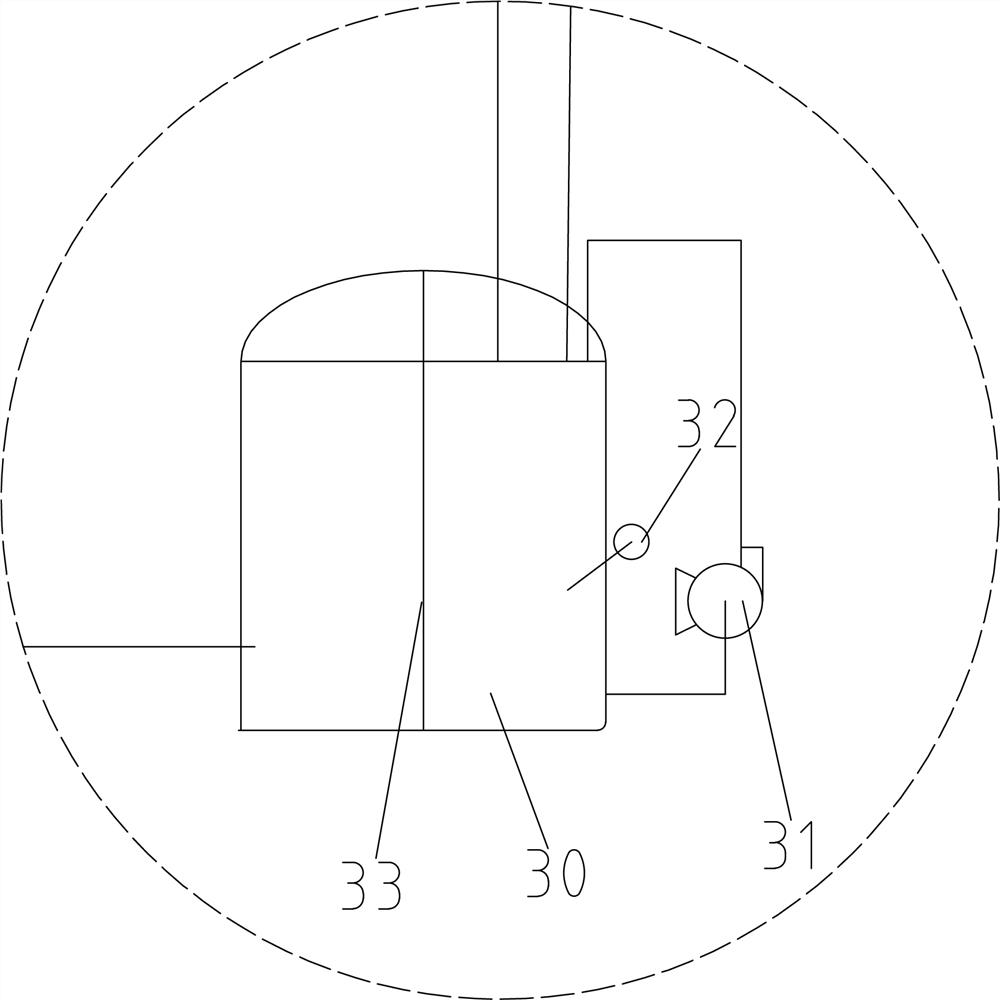

[0022] see Figure 1-Figure 2 .

[0023] The invention discloses a device for producing ammonium sulfate from dye sulfuric acid wastewater, which includes a first decolorization system 100, a neutralization system 200, a second decolorization system 300, and a fine filtration system 400. The neutralization system 200 includes sequentially connected neutralization Material pump 11, neutralization pipeline reactor 13, neutralization buffer tank 15, neutralization filter press pump 16, neutralization filter press 17 and neutralization filtrate tank 18, after the initial mother liquor water is decolorized through the first decolorization system 100 Transported into the neutralization pipeline reactor 13 by the neutralization feed pump 11, and neutralized with the liquefied ammonia inside it, the neutralization pipeline reactor 13 is provided with a neutralization pH ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com