Emulsifying method of ethylene-vinyl acetate copolymer

A vinyl acetate and copolymer technology, which is applied in the emulsification field of ethylene-vinyl acetate copolymer, can solve the problems of demand, large particle size of EVA emulsion, low heat sealing temperature, etc., and achieves good emulsion stability and high practicality. The effect of applying meaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

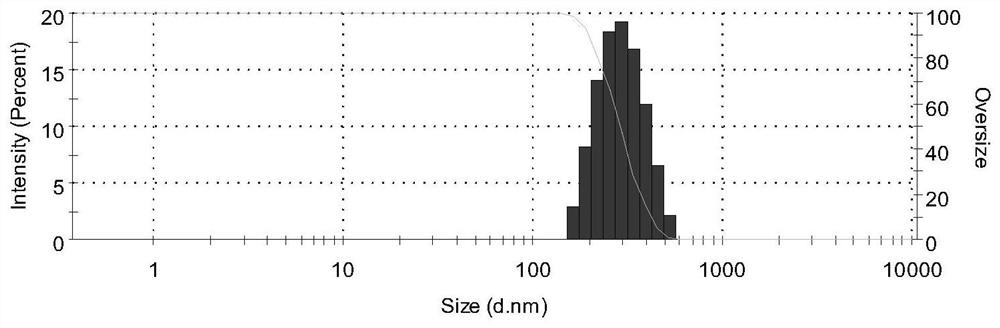

Embodiment 1

[0024] (1) 100g of vinyl acetate content is 28% EVA resin, 10g of cyclohexane, 10g of polyvinyl alcohol and 5g of non-ionic emulsifier op-10 placed in the reactor, 80 ℃ 50rpm rotating speed mechanical stirring Melting under action to form EVA resin in a melt state;

[0025] (2) When the temperature of the EVA resin in the molten state of the reactor is reduced to 70°C, slowly add 5 g of potassium oleate and 20 g of deionized water to the reactor, and stir at a speed of 300 rpm so that the EVA resin in the molten state and water are fully mixed. mix. During the rapid stirring at 800rpm, the viscosity of the EVA melt increases rapidly and turns into a water-in-oil state, that is, the EVA resin in the melt state is the continuous phase, and water is the dispersed phase;

[0026] (3) Continue to add 150g of deionized water in the reactor, and stir at a speed of 200rpm at the same time, the EVA resin in the melt state in the reactor will change into an oil-in-water state because o...

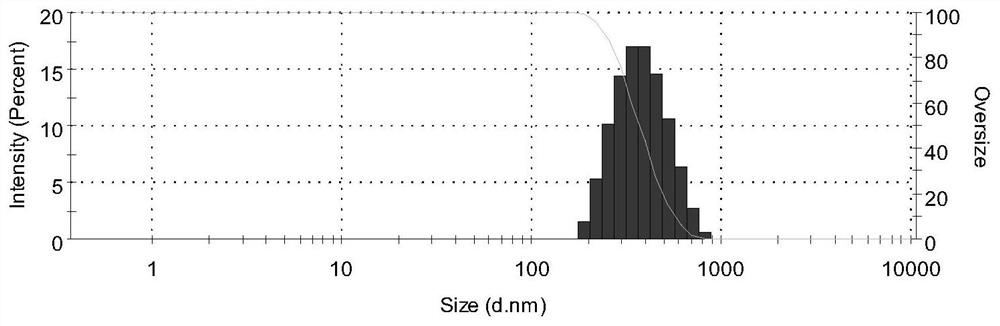

Embodiment 2

[0028] (1) the vinyl acetate content of 100g is 15% EVA resin, the alkyl spirit of 10g, the polyvinyl alcohol of 10g and the nonionic emulsifier Tween 80 of 5g are placed in reactor, 110 ℃ 150rpm mechanical stirring Melting under action to form EVA resin in a melt state;

[0029] (2) When the temperature of the EVA resin in the molten state of the reactor is reduced to 70° C., slowly add 10 g of disproportionated potassium abietate and 30 g of deionized water to the reactor, and stir at 200 rpm so that the EVA resin in the molten state is fully mixed with water. mix. During the rapid stirring process at 1500rpm, the viscosity of EVA melt increases rapidly and turns into a water-in-oil state, that is, the EVA resin in the melt state is the continuous phase, and water is the dispersed phase;

[0030] (3) Continue to add 140g of deionized water to the reactor, and stir rapidly at the same time. The EVA resin in the melt state in the reactor will change to an oil-in-water state d...

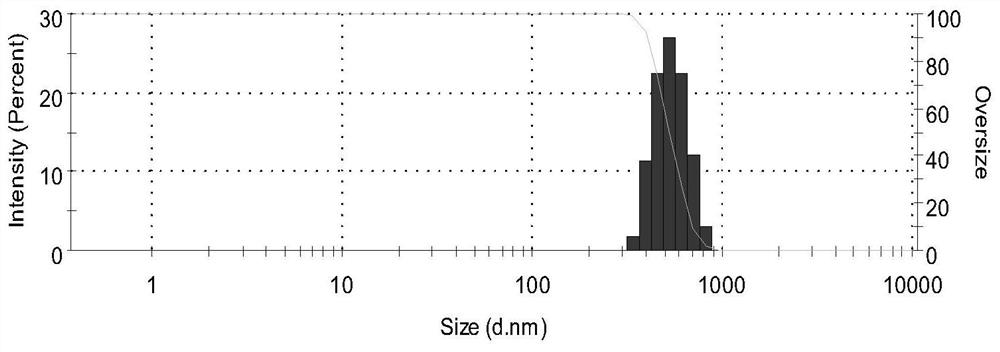

Embodiment 3

[0032] (1) the vinyl acetate content of 100g is the EVA resin of 33%, the alkyl solvent naphtha of 5g and 5g cyclohexane, the polyvinyl alcohol of 10g and the nonionic emulsifier castor oil polyoxyethylene ether 5g and polyoxyethylene ether of 5g 5g of ethylene glycol is placed in the reaction kettle, and melted under the action of mechanical stirring at 90°C and 200rpm to form a molten EVA resin;

[0033] (2) When the temperature of the EVA resin in the melt state of the reactor is reduced to 75°C, slowly add 10 g of potassium ricinoleate and 20 g of deionized water to the reactor, and stir at 100 rpm to make the EVA resin in the melt state and water Mix well. During the stirring process at 1800rpm, the viscosity of the EVA melt increases rapidly and turns into a water-in-oil state, that is, the EVA resin in the melt state is the continuous phase, and water is the dispersed phase;

[0034] (3) Continue to add 180g of deionized water to the reactor, and stir at 200rpm. The EV...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com