A kind of immobilized algae ball and its preparation method and application

A technology of algae balls and algae, which is applied in the field of immobilized algae balls and its preparation, can solve the problems of high mechanical strength of immobilized algae balls, easy decomposition of immobilized algae balls, and inability to store for a long time, so as to facilitate large-scale production, Good stability and activity, high stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

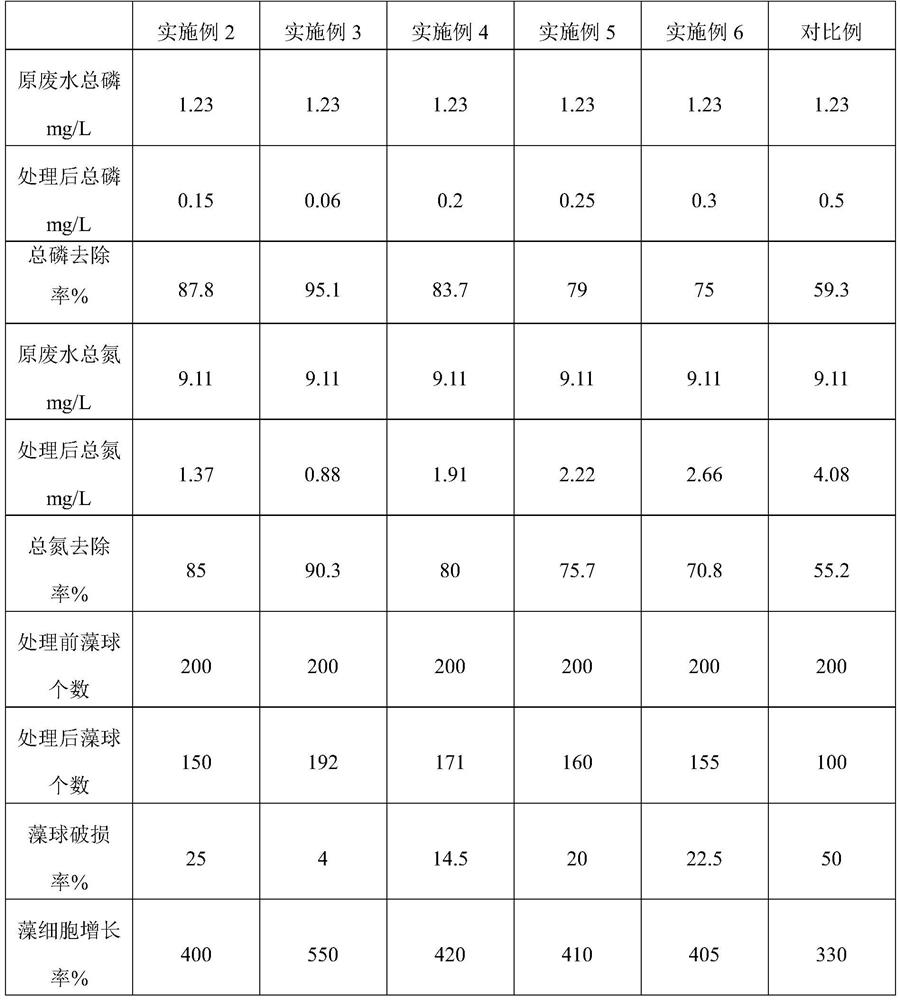

Examples

Embodiment 1

[0031] Cultivation of microbial algae liquid: inoculate Sclerophytum in BG11 medium, and cultivate for 8 days under the conditions of temperature 25-28°C, light intensity 5000±500Lx, and pH 6-7 to prepare microbial algae liquid.

Embodiment 2

[0033] Preparation of algae mixture: heat 8ml of acetyl tri-n-butyl citrate (ATBC) to 100°C and then cool down to 70-80°C for later use;

[0034] Add 2g of sodium alginate into 100ml of water, stir evenly at 60 to 70°C (sodium alginate is added in four times, 0.5g each time), sterilize with high temperature steam at 121°C for 20min, add chitosan 2g, stir well and then ultrasonically After ultrasonic treatment in the crusher for 1 min, add the cooled acetyl tri-n-butyl citrate, mix thoroughly and the temperature drops below 25°C.

[0035] Preparation of algae cross-linking agent: Add 25g of boric acid into 500ml of water, stir well to dissolve, add 5g of calcium chloride and continue to stir evenly, and adjust the pH to 7.0-7.4 with 2mol / L NAOH solution, and use it after high-temperature steam sterilization at 121°C.

[0036] Add the microbial algae solution prepared in Example 1 into the algae mixture at a volume ratio of 0.9:1, and stir evenly to obtain the embedding solution...

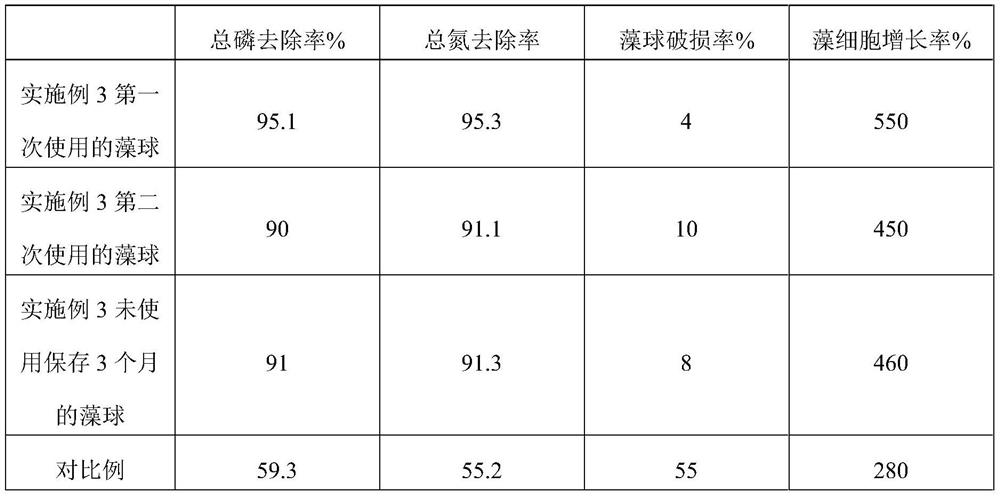

Embodiment 3

[0038] Preparation of algae mixture: heat 10ml of acetyl tri-n-butyl citrate (ATBC) to 100°C and then cool down to 70-80°C for later use;

[0039] Add 2.5g of sodium alginate into 100ml of water, stir evenly at 60 to 70°C (sodium alginate is added in four times), sterilize with high-temperature steam at 121°C for 20 minutes, add chitosan 3.5g, stir evenly, and place in an ultrasonic breaker After ultrasonic treatment for 1 min, add the cooled acetyl tri-n-butyl citrate, mix thoroughly and the temperature drops below 25°C.

[0040] Preparation of algae cross-linking agent: Add 25g of boric acid to 500ml of water, fully stir to dissolve, add 7.5g of calcium chloride and continue to stir evenly, and adjust the pH to 7.0-7.4 with 2mol / L NAOH solution, and use it after high-temperature steam sterilization at 121°C .

[0041] Add the microbial algae solution prepared in Example 1 into the algae mixture at a volume ratio of 1:1, and stir evenly to obtain the embedding solution; use ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com