Method for visualizing complex magnetic field

A magnetic field and complex technology, applied in the field of visualization of complex magnetic fields, can solve the problems of easy agglomeration, non-uniform size of colloidal nanocrystal clusters, and inability to reuse, and achieve the effect of low cost, high sensitivity and high resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The present invention also provides a method for preparing the above-mentioned magnetic monodisperse particles, comprising the following steps:

[0046] A) In the presence of a catalyst, add tetraethyl orthosilicate dropwise to the dispersion of the modified nanoparticles to react, and the iron-containing nanoparticles are non-spherical;

[0047] B) Calcining the reaction product obtained in step B) under a reducing atmosphere to obtain a magnetic substance;

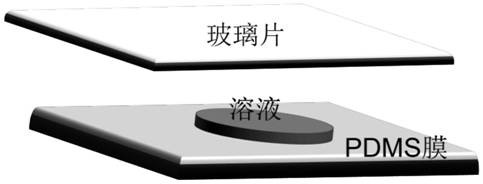

[0048] C) Dispersing the magnetic substance in a solvent to obtain a colloidal crystal solution.

[0049]Wherein, the nanoparticles are selected from α-Fe 2 o 3 Nanoparticles or FeOOH nanoparticles, Ni(OH) 2 nanoparticles.

[0050] The α-Fe 2 o 3 Nanoparticles are prepared as follows:

[0051] Dissolve the water-soluble iron source compound and sodium dihydrogen phosphate in water, and conduct a heating reaction to obtain α-Fe 2 o 3 nanoparticles. The water-soluble iron source compound is selected from f...

Embodiment 1

[0103] 1. Fe 3 o 4 @SiO 2Synthesis of nanorods

[0104] 1.623g FeCl 3 ·6H 2 O was dissolved in 120 mL of deionized water, and the solution was heated to 90 °C for 4 h with magnetic stirring. Afterwards, the solution was centrifuged and washed three times, and the precipitate obtained by centrifugation, ie, FeOOH nanorods, was redispersed in water. A solution containing 270 mg of FeOOH nanorods was added to a polyacrylic acid sodium salt solution (prepared by mixing 64.8 mg of polyacrylic acid, 36 mg of sodium hydroxide, and 9 mL of deionized water), and stirred for twelve hours. After centrifugal washing, the modified FeOOH nanorods were redispersed in 30 mL of water. Then 180 mL of deionized water and 9 mL of 28% ammonia were added to the solution under sonication. Thereafter, 900 μL of tetraethyl orthosilicate (TEOS) was added every 30 minutes under magnetic stirring until the total amount of TEOS reached 9 mL. After continuing the reaction for 30 min, FeOOH@SiO was ...

Embodiment 2

[0110] 1. Ellipsoid Fe 3 o 4 @SiO 2 Synthesis

[0111] 0.85g FeCl 3 ·6H 2 O and 3.1 mg NaH 2 PO 4 It was sonicated in 120 mL of deionized water at room temperature, and then placed in an oven at 100°C for 48 hours. During this process, the solution gradually became cloudy, changing color from light yellow to dark red. Afterwards, the solution was centrifuged and washed three times, and the precipitate obtained by centrifugation, that is, the ellipsoidal α-Fe 2 o 3 Redisperse in water. Containing 50mgα-Fe under ultrasound 2 o 3 0.2 g of PVP was added to the aqueous solution (20 mL). After sonicating for 1 hour, it was stirred for over 2 hours, and centrifuged at 11000 rpm for 30 minutes to remove excess PVP in the solution. The centrifuged precipitate was redispersed in 6 mL of deionized water, and 40 mL of ethanol and 2 mL of ammonia water were added thereto under ultrasonication. Afterwards, 200 μL TEOS was added every half hour under magnetic stirring until the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Long axis size | aaaaa | aaaaa |

| Minor axis size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com