Waste residue field reclamation soil matrix as well as preparation method and application

A technology for waste slag field and soil, which is applied in the fields of botanical equipment and methods, application, substrate fertilizer, etc., can solve the problems of difficult reclamation of waste slag field, difficult disposal of large amount of engineering waste slag, and long time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

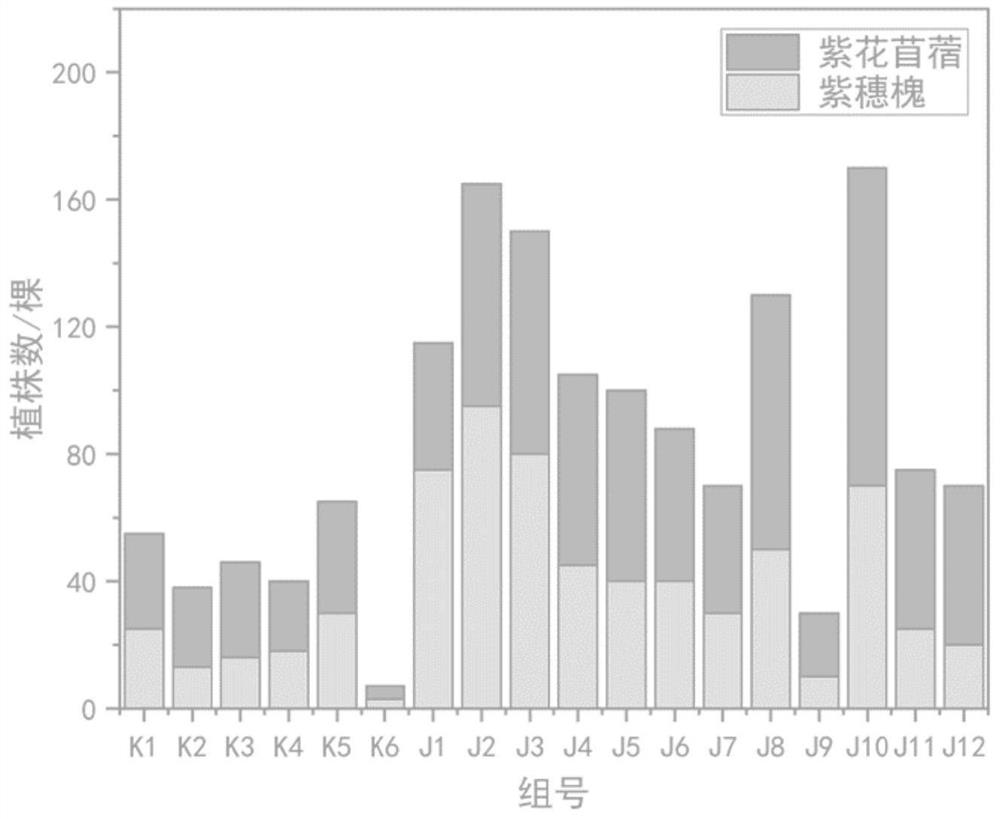

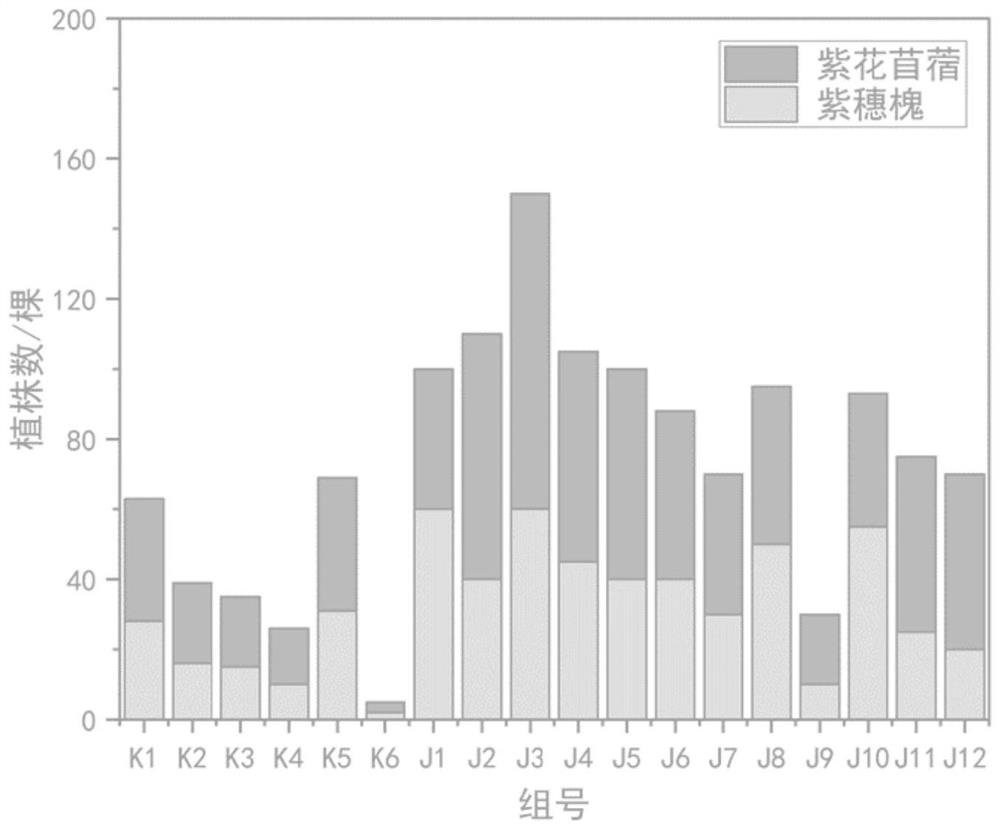

Embodiment 1

[0043] Example 1 (J1)

[0044] The present embodiment provides a soil matrix for reclamation of expressway waste slag field, which consists of 73.6% red clay, 18.4% engineering waste, 3% organic fertilizer, and 5% pine needles.

[0045] The red clay and engineering waste were taken from the Yunmogou waste yard of Yangmang Expressway, Yangcheng City, Shanxi Province, and were sieved and air-dried for later use. The basic physical and chemical properties of red clay are alkaline hydrolysis nitrogen content of 80mg / kg, available phosphorus content of 6.6mg / kg, available potassium content of 68mg / kg, organic matter content of 13.4g / kg, pH of 7.01, and the gradation of red clay: 3 . The basic physical and chemical properties of engineering waste slag are alkaline hydrolysis nitrogen 9.8mg / Kg, available phosphorus content 2.3mg / Kg, available potassium content 14.1mg / Kg, organic matter content 0.3g / kg, pH 7.63, engineering waste slag The particle size ratio of ≤0.25mm accounts for 12...

Embodiment 21

[0054] Example 2.1 (J2)

[0055] Different from Example 1, the soil matrix is composed of 72% red clay, 18% engineering waste, 5% organic fertilizer, and 5% shredded pine needles by mass percentage.

Embodiment 22

[0056] Example 2.2 (J3)

[0057] The difference from Example 1 is that the soil matrix is composed of 69.6% red clay, 17.4% engineering waste, 8% organic fertilizer and 5% shredded pine needles in terms of mass percentage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com