Waste ammonia gas recovery device for gallium nitride production furnace

A recovery device, gallium nitride technology, applied in the chemical industry, climate sustainability, air quality improvement, etc., can solve the problem of insufficient ammonia recovery, ineffective use of ammonia heat, and exhaust gas that does not meet the specified emission standards and other problems to achieve the effect of improving the efficiency of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

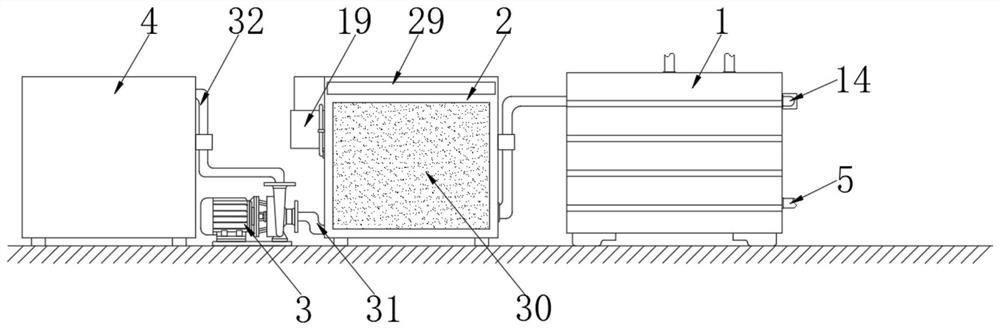

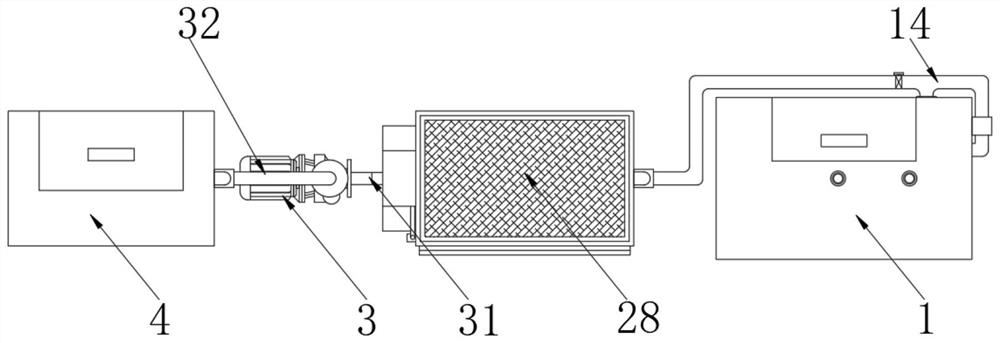

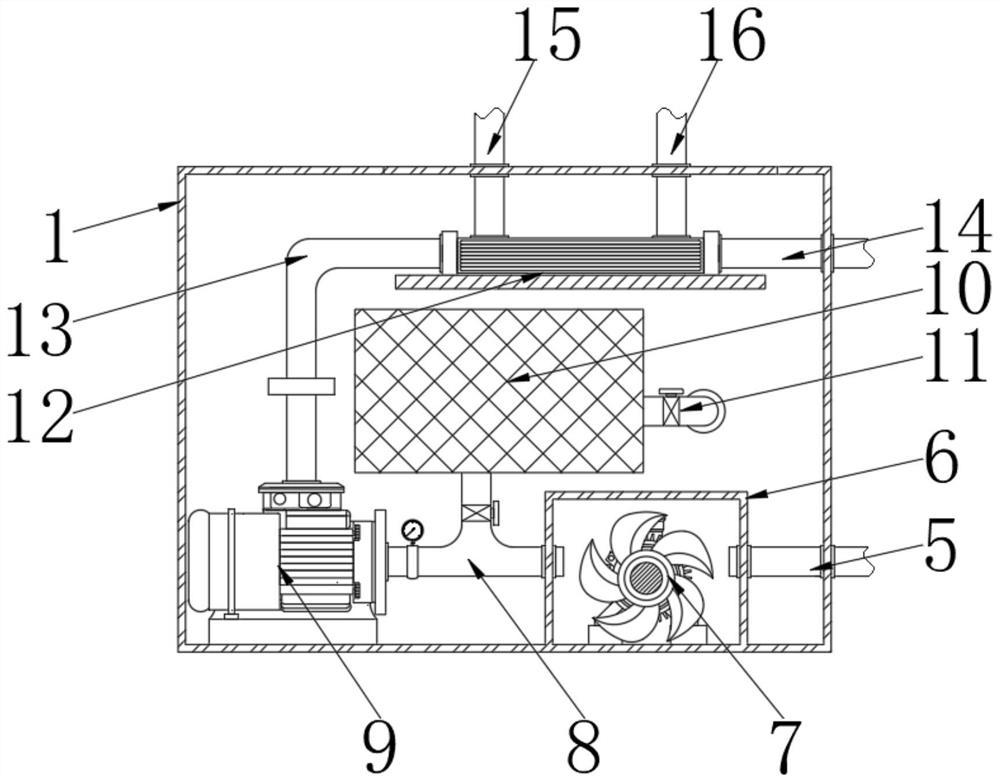

[0031] A waste ammonia gas recovery device for a gallium nitride production furnace, comprising a heat recovery box 1, an ammonia gas recovery box 2, a liquid pump 3, and a liquid storage box 4. The left side of the heat recovery box 1 is connected to an intake pipe 5 for heat recovery The bottom of the inner cavity of the box 1 is fixedly connected with a No. 1 mechanical box 6, and the bottom of the No. 1 mechanical box 6 inner cavity is fixedly connected with a suction fan 7. The suction fan 7 includes a motor, a rotating shaft and fan blades. The power supply is electrically connected. The left side of the No. 1 mechanical box 6 is connected to a No. 1 exhaust pipe 8. The bottom of the inner cavity of the heat recovery box 1 is fixedly connected to the left side of the No. 1 mechanical box 6. The compressor 9 is connected to the The external power supply is electrically connected, the back of the inner cavity of the heat recovery box 1 is fixedly connected with the heat pre...

Embodiment 2

[0033] A waste ammonia gas recovery device for a gallium nitride production furnace, comprising a heat recovery box 1, an ammonia gas recovery box 2, a liquid pump 3, and a liquid storage box 4. The left side of the heat recovery box 1 is connected to an intake pipe 5 for heat recovery The bottom of the inner cavity of the box 1 is fixedly connected with a No. 1 mechanical box 6, and the bottom of the No. 1 mechanical box 6 inner cavity is fixedly connected with a suction fan 7. The suction fan 7 includes a motor, a rotating shaft and fan blades. The power supply is electrically connected. The left side of the No. 1 mechanical box 6 is connected to a No. 1 exhaust pipe 8. The bottom of the inner cavity of the heat recovery box 1 is fixedly connected to the left side of the No. 1 mechanical box 6. The compressor 9 is connected to the The external power supply is electrically connected, the back of the inner cavity of the heat recovery box 1 is fixedly connected with the heat pre...

Embodiment 3

[0035] A waste ammonia gas recovery device for a gallium nitride production furnace, comprising a heat recovery box 1, an ammonia gas recovery box 2, a liquid pump 3, and a liquid storage box 4. The left side of the heat recovery box 1 is connected to an intake pipe 5 for heat recovery The bottom of the inner cavity of the box 1 is fixedly connected with a No. 1 mechanical box 6, and the bottom of the No. 1 mechanical box 6 inner cavity is fixedly connected with a suction fan 7. The suction fan 7 includes a motor, a rotating shaft and fan blades. The power supply is electrically connected. The left side of the No. 1 mechanical box 6 is connected to a No. 1 exhaust pipe 8. The bottom of the inner cavity of the heat recovery box 1 is fixedly connected to the left side of the No. 1 mechanical box 6. The compressor 9 is connected to the The external power supply is electrically connected, the back of the inner cavity of the heat recovery box 1 is fixedly connected with the heat pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com