Large treatment system for degrading kitchen garbage through phase-change water production and treatment method of system

A kitchen waste and treatment system technology, applied in the directions of hydrolytic enzymes, chemical instruments and methods, microorganism-based methods, etc., can solve the problems of high cost of enzyme preparations, cannot be widely promoted, etc., and achieves stable and reliable operation and convenient assembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

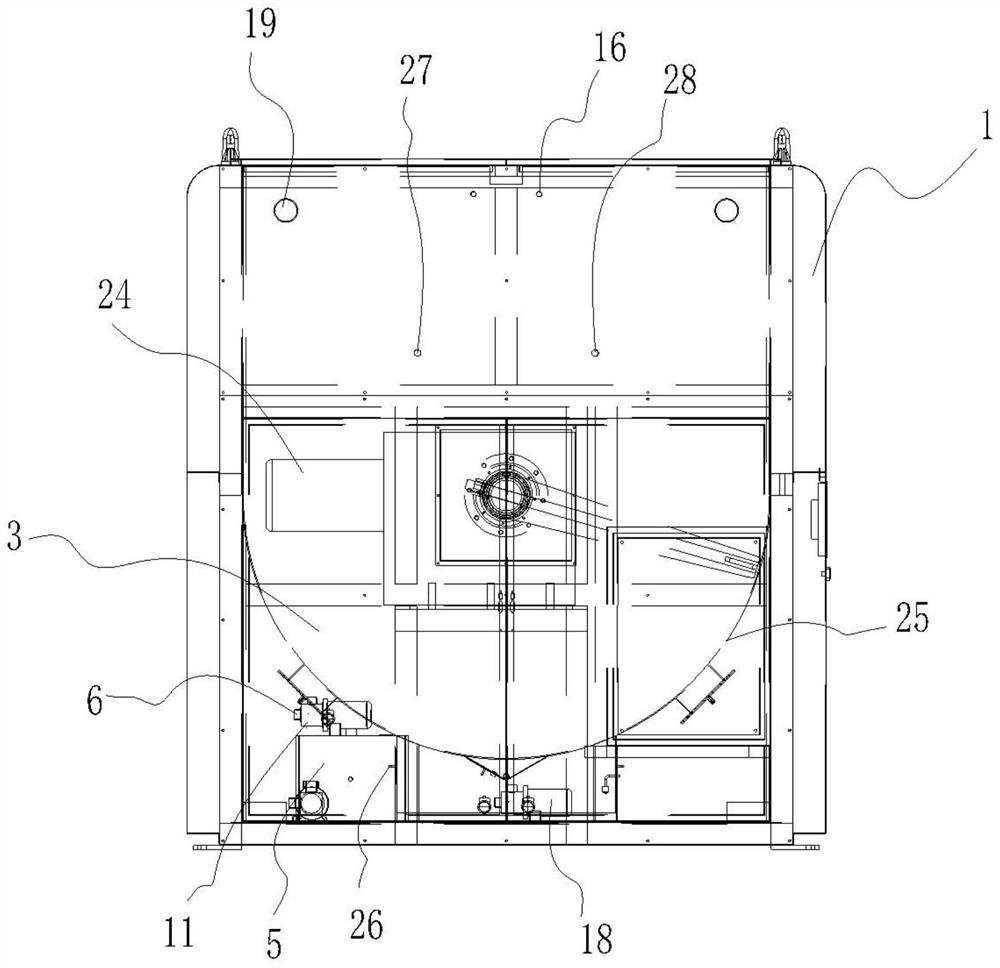

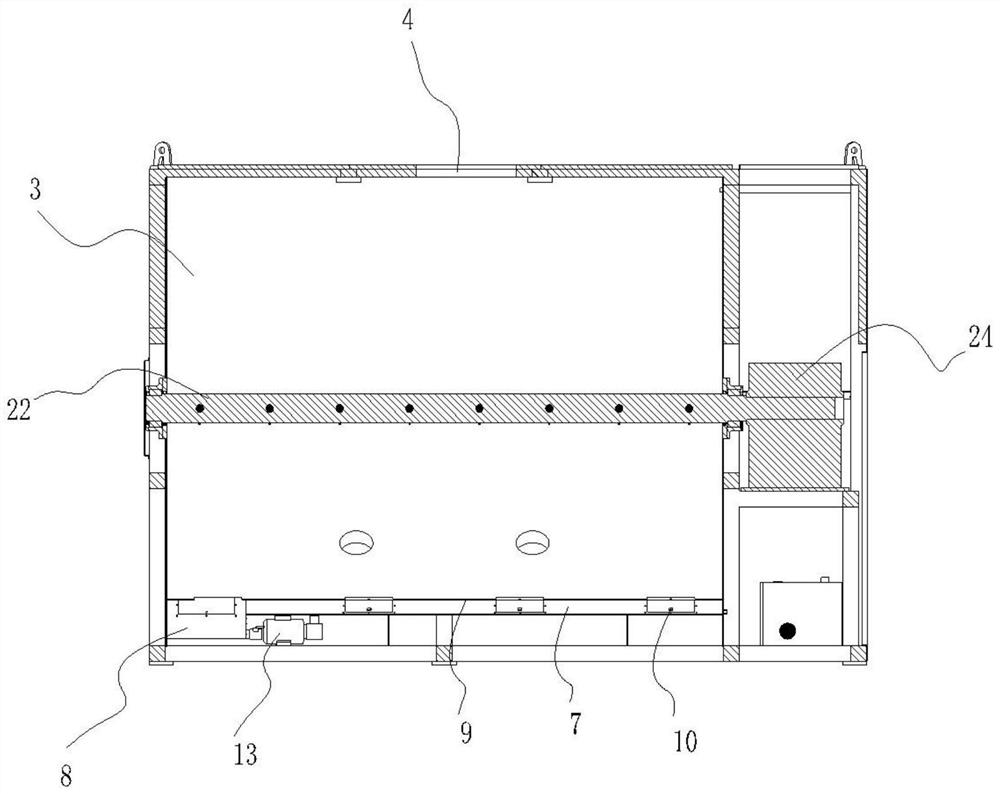

[0109] Embodiment 1: As shown in the figure, a large-scale food waste phase-change water-making degradation treatment system includes a box body 1, an intelligent control system 2 and garbage, and the box body 1 is provided with a garbage biodegradation system for decomposing garbage. Bin 3, the upper part of the garbage biodegradation bin 3 is provided with a garbage feeding port 4 extending upward to the upper part of the box body 1, and the garbage enters the garbage biodegrading bin 3 through the garbage feeding port 4;

[0110] The box body 1 is provided with an inoculum box 5, and the intelligent control system 2 puts the inoculum in the inoculum box 5 into the garbage biodegradation bin 3 to mix the garbage with the inoculum. The biodegradation bin 3 is provided with a mixing assembly for uniformly mixing garbage and bacterial agents.

[0111] As preferably, the bacterial agent box 5 is communicated with the upper end of the garbage biodegradation bin 3 through the bact...

Embodiment 2

[0186] Embodiment 2: A special degrading bacterial agent applied to a large-scale kitchen waste phase-change water production degradation treatment system: it includes composite microorganisms, and the composite microorganisms are composed of the following raw materials in parts by mass:

[0187] 5.5 parts of Clostridium irregularis, 5.5 parts of Ephedra irregularis, 10 parts of Geosporum, 10 parts of Acetobacter, 36 parts of Clostridium, 26 parts of Clostridium thiogenes, 5.5 parts of Bacteroides.

[0188] A preparation method of a special degrading bacterial agent applied to a large-scale kitchen waste phase-change water-making degradation treatment system is carried out according to the following steps:

[0189] (1), separately prepare microbial fermented liquid:

[0190] 1) Preparation method of Clostridium irregular microbial fermentation broth:

[0191] Clostridium irregularis is cultivated on the enhanced Clostridium medium at an ambient temperature of 25°C, firstly cu...

Embodiment 3

[0237] Embodiment 3: A special degrading bacterial agent applied to a large-scale kitchen waste phase-change water production degradation treatment system: it includes composite microorganisms, and the composite microorganisms are composed of the following raw materials in parts by mass:

[0238] 6 parts of Clostridium irregularis, 6 parts of Ephedra irregularis, 11 parts of Geosporum, 11 parts of Acetobacter, 40 parts of Clostridium, 30 parts of Clostridium thiogenes, 6 parts of Bacteroides.

[0239] A preparation method of a special degrading bacterial agent applied to a large-scale kitchen waste phase-change water-making degradation treatment system is carried out according to the following steps:

[0240] (1), separately prepare microbial fermented liquid:

[0241] 1) Preparation method of Clostridium irregular microbial fermentation broth:

[0242] Clostridium irregularis is cultivated on the enhanced Clostridium medium at an ambient temperature of 25°C, firstly cultured...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com