Continuous preparation method of 1-cyano-2-propenyl acetate

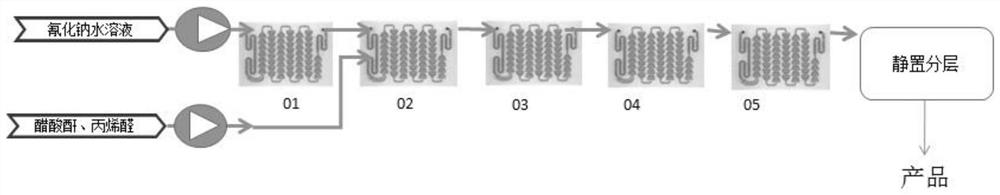

A technology of acryl acetate and cyano, which is applied in the field of continuous preparation of 1-cyano-2-propenyl acetate, can solve the problems of unfavorable industrial production, hidden safety hazards, and high production costs, and achieve labor Reduced strength, small footprint, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

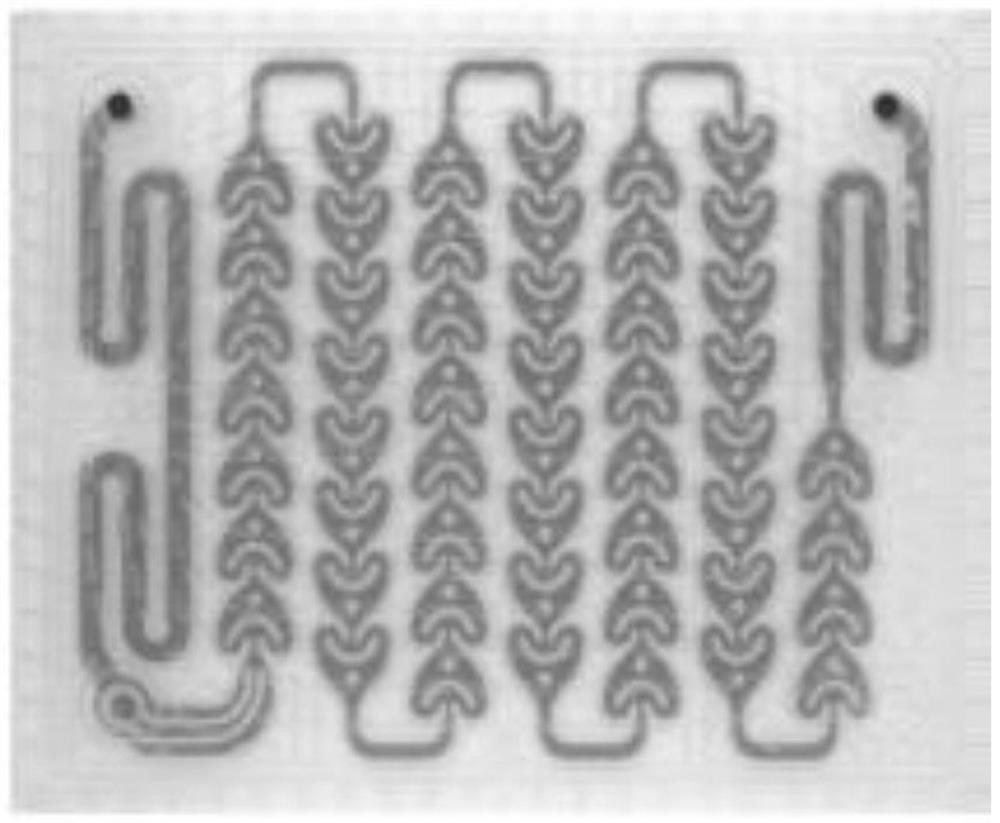

Embodiment 1

[0043] 56g of acrolein and 102g of acetic anhydride are made into a mixed solution of acrolein and acetic anhydride for use, 49g of sodium cyanide and 114.3g of water are made into a 30% aqueous solution of sodium cyanide for use, and the temperature of the microchannel plate jacket oil is adjusted to -10°C, after the oil temperature stabilizes to -10°C, use the metering pump 1 to inject the sodium cyanide aqueous solution into the pre-cooling module of the microchannel reactor, then enter the reaction module, and use the metering pump 2 to mix the acetic anhydride and acrolein liquid into the reaction module of the microchannel reactor, wherein the feed rate of acetic anhydride and acrolein mixed solution is 10g / min (acrolein 0.0633mol / min, acetic anhydride 0.0633mol / min), and the feed rate of sodium cyanide aqueous solution is 10.339g / min (sodium cyanide 0.0633mol / min), the residence time of the reaction solution in the reactor is 96s, feed 10min, collect the microchannel eff...

Embodiment 2

[0045] 56g of acrolein and 102g of acetic anhydride are made into a mixed solution of acrolein and acetic anhydride for use, 49g of sodium cyanide and 114.3g of water are made into a 30% aqueous solution of sodium cyanide for use, and the temperature of the microchannel plate jacket oil is adjusted to 0°C, after the oil temperature stabilizes to 0°C, use the metering pump 1 to pump the sodium cyanide aqueous solution into the pre-cooling module of the microchannel reactor, then enter the reaction module, and use the metering pump 2 to pump the mixed solution of acetic anhydride and acrolein Enter the reaction module of microchannel reactor, wherein the feed rate of acetic anhydride and acrolein mixed solution is 10g / min (acrolein 0.0633mol / min, acetic anhydride 0.0633mol / min), the sodium cyanide aqueous solution feed rate is 10.339g / min (sodium cyanide 0.0633mol / min), the residence time of the reaction solution in the reactor is 96s, and the feed is 10min, and the microchannel...

Embodiment 3

[0047]56g of acrolein and 102g of acetic anhydride are made into a mixed solution of acrolein and acetic anhydride for use, 49g of sodium cyanide and 114.3g of water are made into a 30% aqueous solution of sodium cyanide for use, and the temperature of the microchannel plate jacket oil is adjusted to -10°C, after the oil temperature stabilizes to -10°C, use the metering pump 1 to inject the sodium cyanide aqueous solution into the pre-cooling module of the microchannel reactor, then enter the reaction module, and use the metering pump 2 to mix the acetic anhydride and acrolein liquid into the reaction module of the microchannel reactor, wherein the feed rate of acetic anhydride and acrolein mixed solution is 20g / min (acrolein 0.1266mol / min, acetic anhydride 0.1266mol / min), and the feed rate of sodium cyanide aqueous solution is 20.678g / min (sodium cyanide 0.1266mol / min), the residence time of the reaction solution in the reactor is 48s, the feed is 5min, the microchannel efflue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com