A kind of epoxy resin curing agent composition and preparation method thereof, a kind of epoxy resin composition

A technology of epoxy resin curing and epoxy resin, applied in the field of epoxy resin curing agent composition and its preparation, and epoxy resin composition, can solve the problems of inability to improve curing reactivity and crosslinking density, and achieve good durability Thermal properties, increasing crosslink density, improving fracture toughness and elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1) Add the IPDI trimer slowly to the alkylamino imidazole (2-imidazolyl-2-yl-propyl) amine at room temperature (molar ratio is 1:3), and the dropping rate is 1 drop / s, After the dropwise addition, the reaction was continued for 0.5 hours, and the reaction temperature was 20° C. to obtain the (2-imidazolyl-2-yl-propyl)amine-terminated IPDI trimer; (2) adding the obtained in (1) Epoxy resin (10wt%) and IPDA (90wt%) were mixed at 20°C to obtain a high toughness medium temperature rapid curing system; (3) The rapid curing system prepared above was mixed with epoxy resin E51 (mass ratio of 30:100) in Mixing evenly at 20°C can obtain a high toughness medium temperature fast curing epoxy resin system.

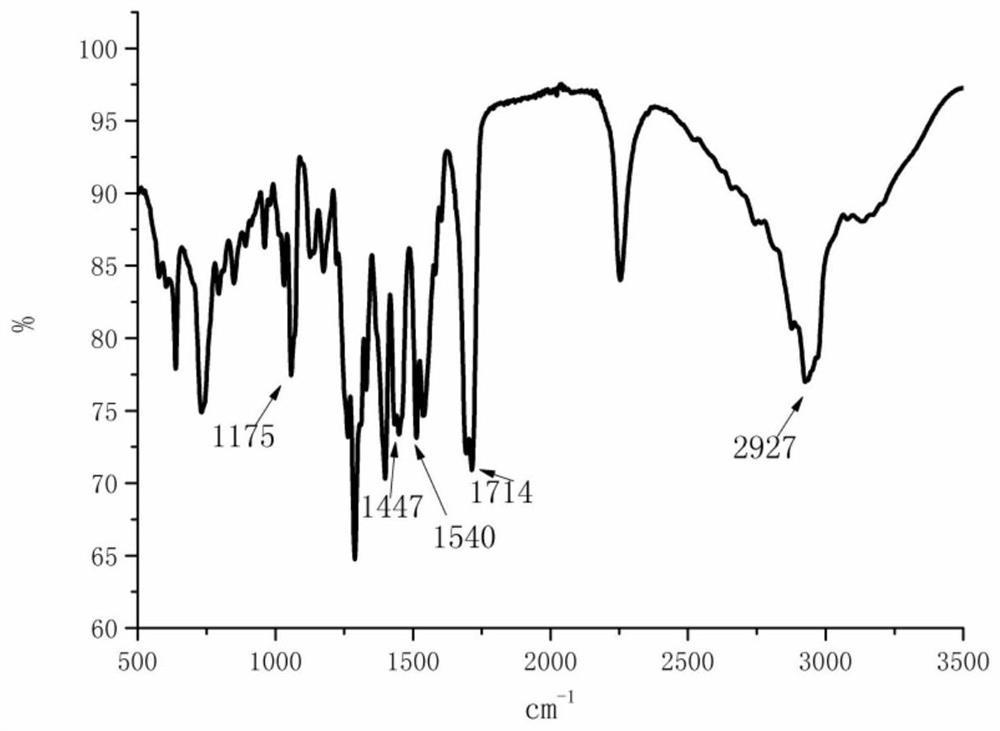

[0041] Wherein, the (2-imidazolyl-2-yl-propyl) amine-terminated IPDI trimer infrared spectrum obtained in step 1) is as follows figure 1 Shown: Measured by infrared, 1714cm -1 is the -C=O stretching vibration peak of urethane and isocyanurate, 1447cm -1 It is the ring vibrat...

Embodiment 2

[0044] 1) Slowly add HDI trimer (WANNATE HT-600) to alkylaminoimidazole (2-imidazolyl-2-yl-ethyl)amine at room temperature (molar ratio is 1:4), and the dropping rate is 2 drops / s, continue to react for 1 hour after the dropwise addition, the reaction temperature is 30 ° C, and the reaction obtains (2-imidazolyl-2-yl-ethyl)amine-terminated HDI trimer; (2) (2) 1) The adduct (20 wt %) obtained in 40° C. is mixed with diaminodicyclohexyl methane (WANAMINE HMDA) (80 wt %) to obtain a high-toughness medium-temperature fast curing system; (3) The above prepared The rapid curing system and epoxy resin E51 (mass ratio of 20:100) were mixed uniformly at 30°C to obtain a high toughness medium temperature rapid curing epoxy resin system.

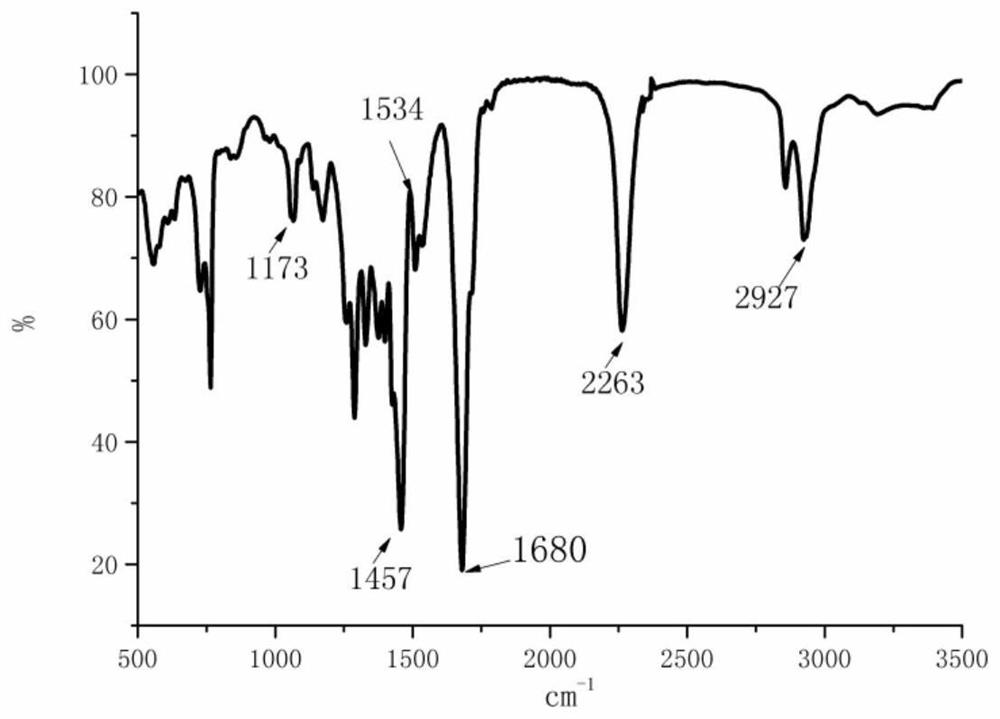

[0045] Wherein, the (2-imidazolyl-2-yl-ethyl)amine-terminated HDI trimer infrared spectrum obtained in step 1) is as follows figure 2 Shown: Measured by infrared, 1457cm -1 is the characteristic peak of HDI trimer, 1680cm --1 C=O stretching vibrati...

Embodiment 3

[0048] 1) MDI dimer is slowly added dropwise (mol ratio is 1:2) in alkylamino imidazole (2-imidazolyl-2-yl-methyl)amine at room temperature, and the dropping rate is 3 drops / s, After the dropwise addition, the reaction was continued for 1.5 hours, and the reaction temperature was 40° C. to obtain a (2-imidazolyl-2-yl-methyl)amine-terminated MDI dimer; (2) adding the obtained in (1) (30wt%) and 1,3-cyclohexanedimethylamine (BAC) (70wt%) were mixed at 60℃ to obtain a high toughness medium temperature rapid curing system; (3) The rapid curing system prepared above was heated at 40℃ Evenly mixing with epoxy resin E51 (mass ratio of 10:100) at high temperature to obtain a high toughness medium temperature fast curing epoxy resin system.

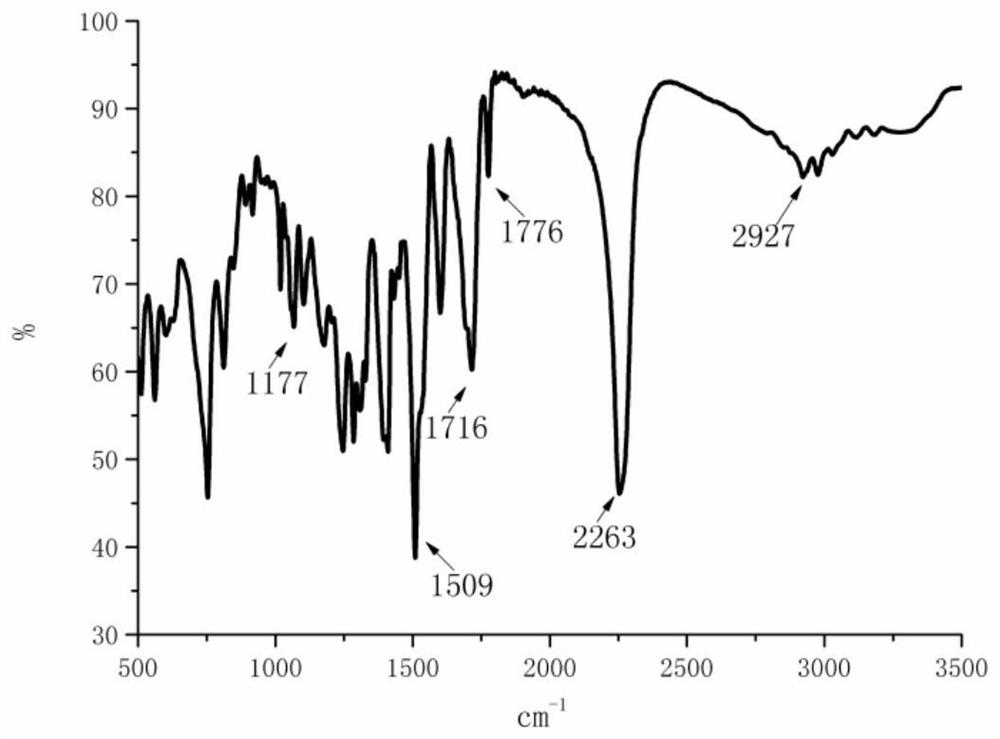

[0049] Wherein, the infrared spectrum of the (2-imidazolyl-2-yl-methyl)amine-terminated MDI dimer obtained in step 1) is as follows image 3 Shown: Measured by infrared, 1776cm -1 -C=O stretching vibration peak of MDI dimer, 1716cm -1 is the -C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com