Copolymerized flame-retardant PA6 material and preparation method thereof

A technology of copolymerization of flame retardant and raw materials, which is applied in the field of flame retardant materials, can solve the problems of igniting other objects, and achieve the effects of good flame retardant efficiency, high carbon formation rate, and fast reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

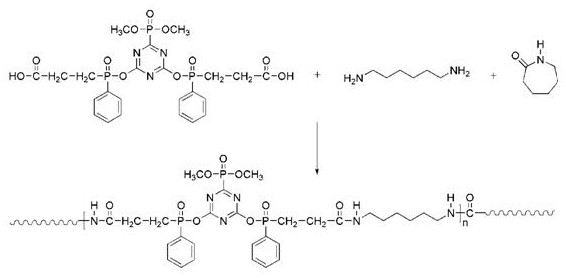

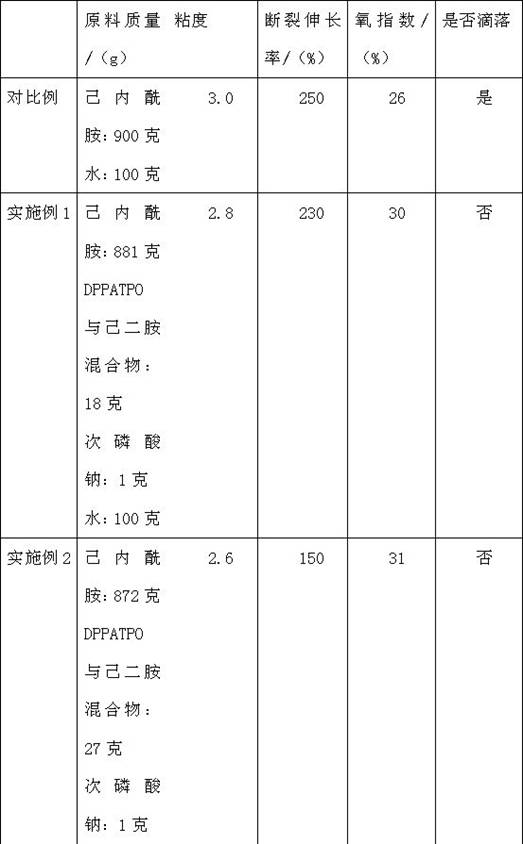

[0029] refer to Figure 1-2 , the invention discloses a copolymerized flame-retardant PA6 material, which is prepared from the following raw materials in parts by weight: DPPATPO, caprolactam, compounds with diamino groups, catalysts, and deionized water.

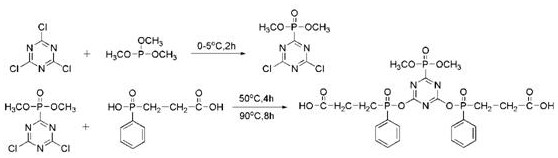

[0030] The DPPATPO is a diacid monomer 2-(dimethyl phosphate)-4,6(2'-carboxyethylphenylphosphinic acid)-s-triazine, and the specific preparation method of the DPPATPO is as follows:

[0031] (1) React the first chlorine atom in the cyanuric chloride molecule with trimethyl phosphite at 0-5°C;

[0032] (2) Substituting the reacted product in step (1) with 2-carboxyethylphenylphosphinic acid (CEPPA) at 40-50°C and 70-90°C respectively;

[0033] (3) Combining the triazine benzene ring structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com