Needle filter solid-phase extraction device for metal organic framework filler

A metal-organic framework and extraction device technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of shortening the extraction time, achieve good extraction effect, recyclable cost, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

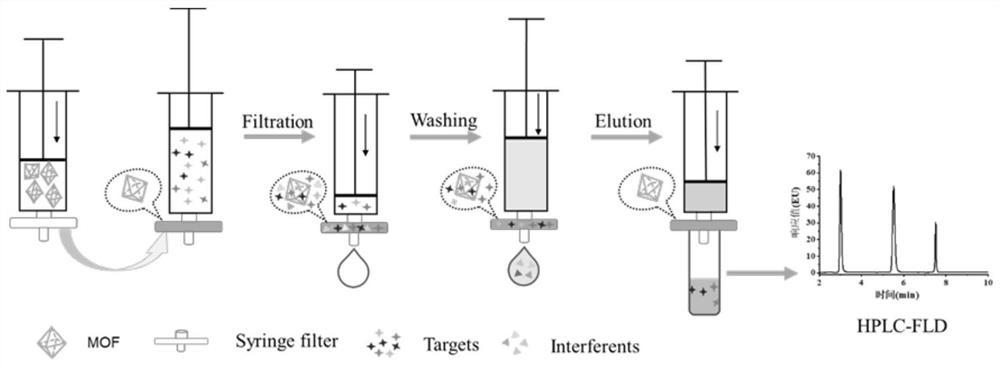

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1 MIL-101 (Cr) is the preparation and extraction application of the syringe filter of filler

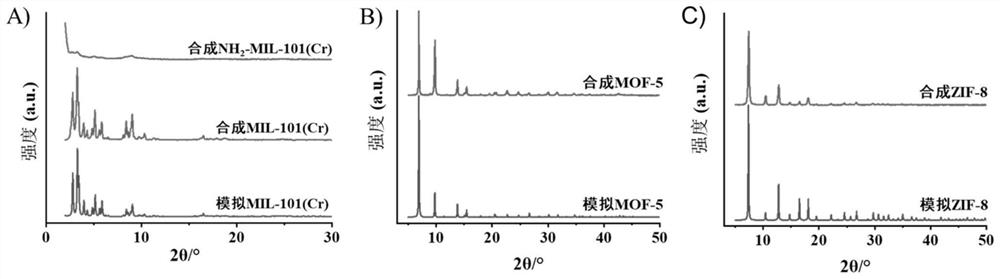

[0032] 1. Synthesis of MIL-101 (Cr): Add 800mg chromium nitrate nonahydrate, 332mg terephthalic acid, 9.6mL water and 0.1 mL hydrofluoric acid (40%) to a 30mL reactor polytetrafluoroethylene liner in sequence middle. After ultrasonic mixing, put the liner into a stainless steel sleeve and seal it, and react at 220°C for 8 hours. After the reaction was completed, the reaction kettle was cooled to room temperature, the solution was transferred to a 50 mL centrifuge tube, centrifuged at 10,000 rpm for 10 min, and the supernatant was discarded. The solid in the lower layer was repeatedly washed with DMF several times to ensure that the washing liquid was colorless, clear and transparent to remove the terephthalic acid and metal salt solution in the channel, and the MIL-101 (Cr) solid was collected by centrifugation; then washed with about 15 mL of absolute ethanol Thr...

Embodiment 2

[0039] Example 2 NH 2 -Preparation of needle filter with MIL-101(Cr) as filler and its extraction application

[0040] NH 2 -Synthesis of MIL-101(Cr): 800mg Cr(NO 3 ) 3 9H 2 O, 360mg 2-aminoterephthalic acid, 200mg NaOH and 15mL deionized water were mixed evenly, transferred to a 50mL polytetrafluoroethylene reaction kettle, and reacted at 150°C for 12h. After the reaction kettle was lowered to room temperature, the solution was transferred to a 50mL centrifuge The tube was centrifuged at 10000rpm for 10min and the supernatant was discarded. The solid in the lower layer was repeatedly washed with DMF several times to remove most of the 2-aminoterephthalic acid, and then washed 3 times with about 15 mL of absolute ethanol to replace the remaining DMF reagent. The solid was collected by centrifugation and dried under vacuum at 40°C overnight.

[0041] All the other steps are the same as steps 2-6 of Example 1.

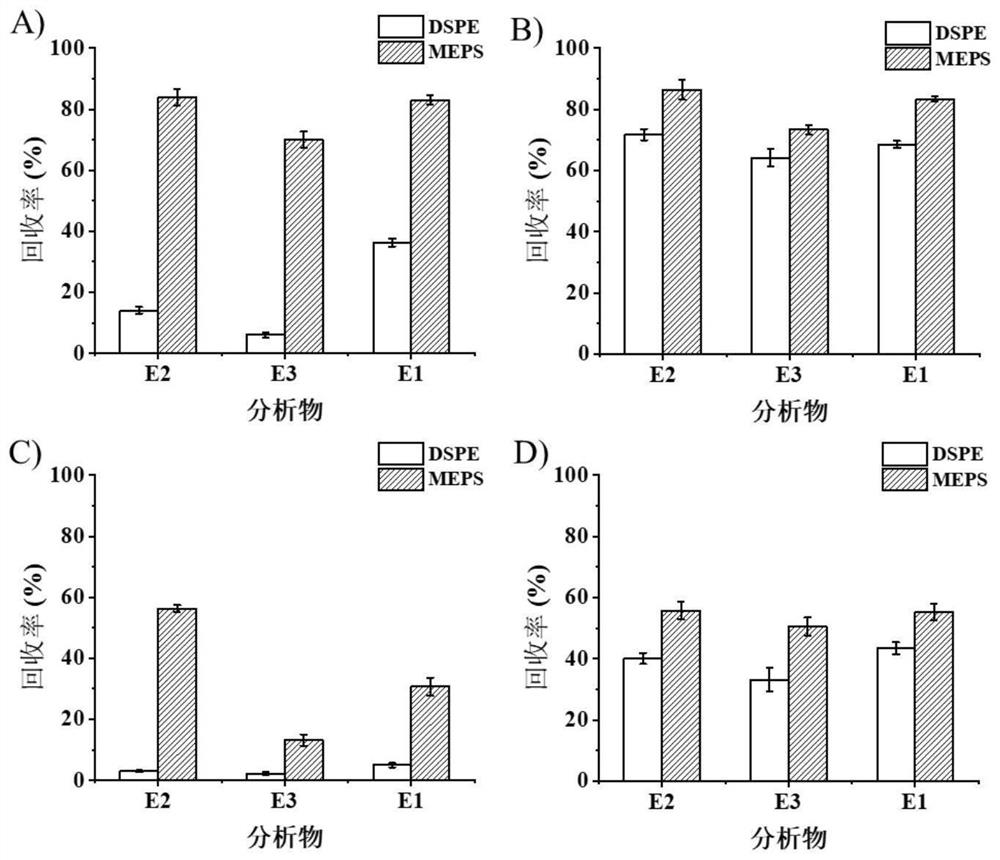

[0042] The result is as image 3 As shown in B, compared wit...

Embodiment 3

[0043] Embodiment 3 MOF-5 is the preparation and extraction application of the syringe filter of filler

[0044] Synthesis of MOF-5: Dissolve 0.50g terephthalic acid in 80mL DMF, sonicate until dissolved, add 1mL triethylamine; take another 1.70g zinc acetate dihydrate, dissolve it in 100mL DMF, sonicate until completely dissolved, then add the above paraffin phthalic acid solution, stirred at room temperature for 4 hours, and centrifuged at 12,000 rpm for 15 minutes to obtain solids that were washed three times with dichloromethane and methanol, collected by centrifugation, and dried overnight at 60° C. under vacuum.

[0045] All the other steps are the same as steps 2-6 of Example 1.

[0046] The result is as image 3 As shown in C, compared with the dispersed solid phase extraction, the recoveries of the three target substances increased from 2.23% to 5.02% to 13.22% to 56.31%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com