SCR denitration system prediction model optimization method based on machine learning

A prediction model and machine learning technology, applied in geotechnical engineering and tunnel engineering, real-time monitoring and forecasting of foundation pit excavation deformation and stability analysis, can solve problems such as precise control of ammonia injection in thermal power plants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

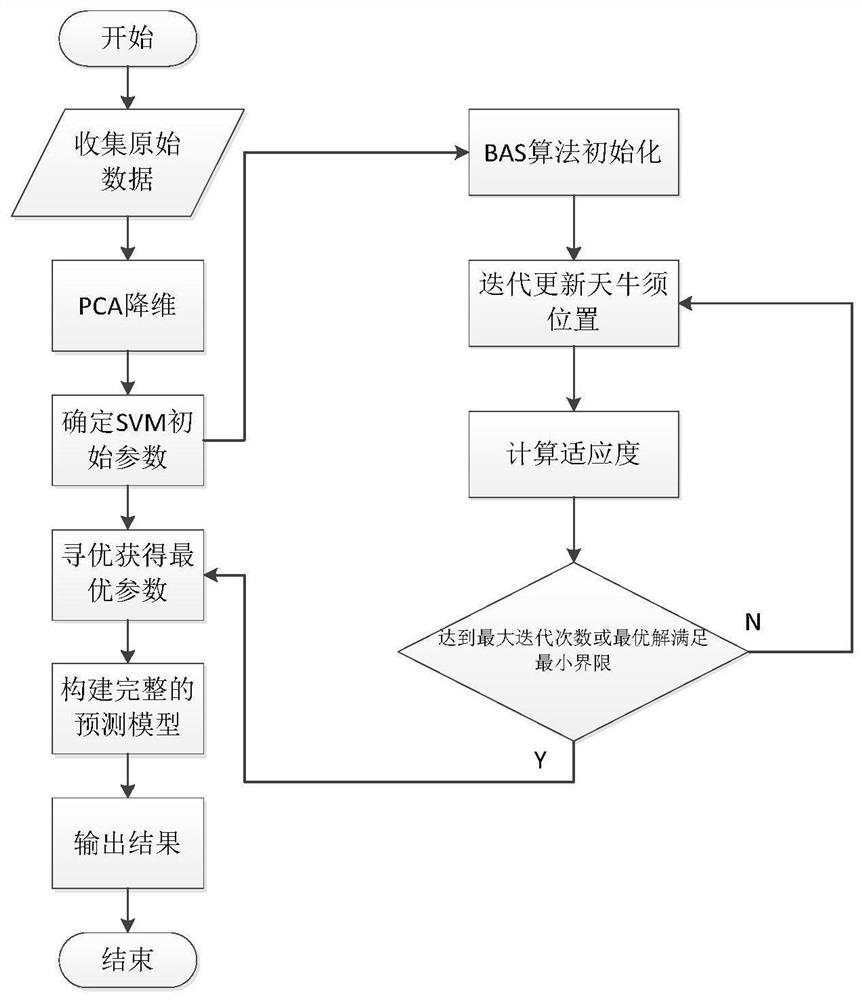

[0082] A machine learning-based SCR denitrification system prediction model optimization method of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

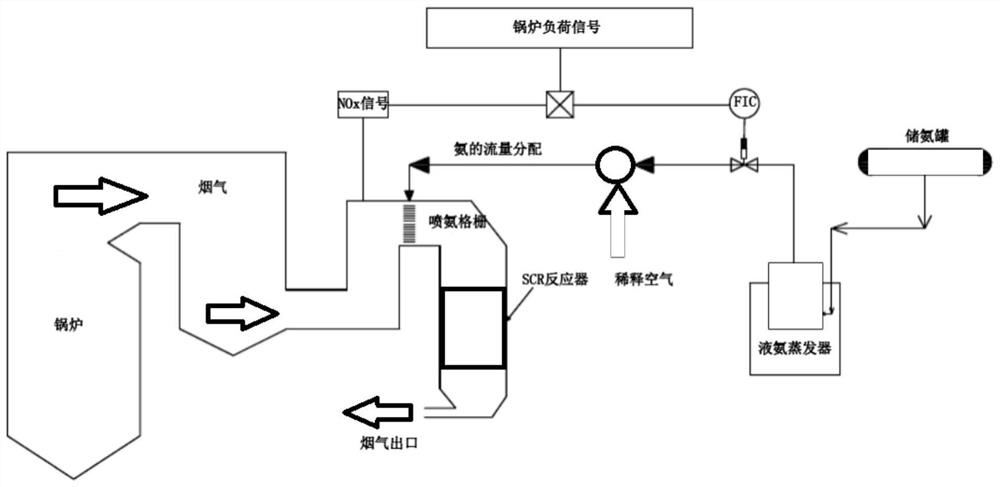

[0083] Such as figure 1 As shown, the pulverized coal is burned in the boiler to form flue gas, which contains NO X , SO 2 Pollutants, such as pollutants, enter the SCR denitrification reactor after being cooled by the heat exchanger. The reactor inlet is equipped with an ammonia injection grid (the ammonia injection grid refers to the ammonia injection pipe and grid), and then the ammonia from the liquid ammonia evaporator After the gas is mixed with the dilution air, the NO in the flue gas X A selective reduction reaction occurs under the action of a catalyst to generate water and ammonia. At present, it is difficult for most coal-fired power plants to accurately control the amount of ammonia injection. Insufficient ammonia injection will ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com