Preparation method of magnetic skeleton

A skeleton and magnetic technology, which is applied in the field of magnetic skeleton preparation by 3D printing technology, can solve the problems of complex iron core structure design, residual magnetism of ferromagnetic materials, narrow measurement frequency band, etc. The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

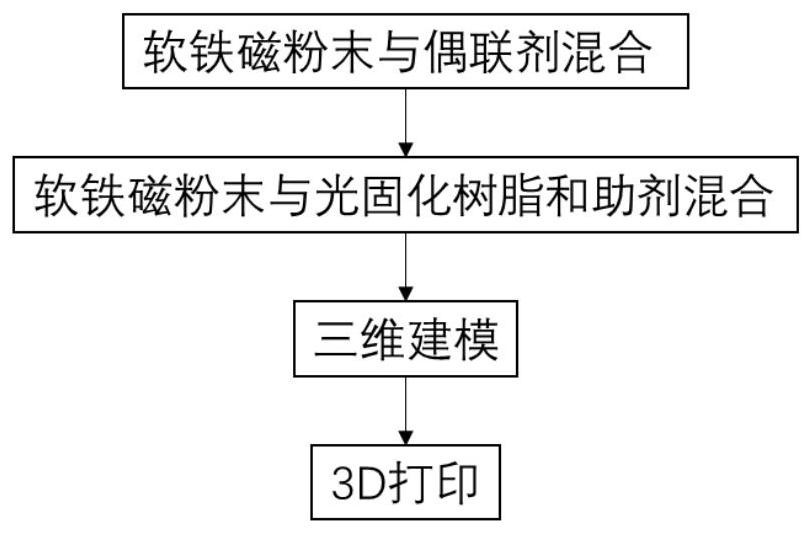

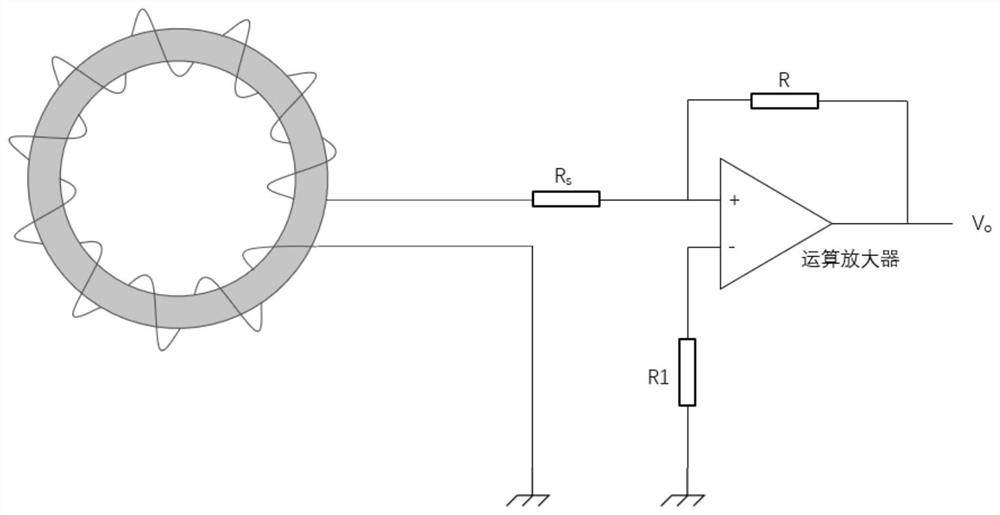

[0036] In this embodiment, silicon steel is used as a soft ferromagnetic material to prepare a magnetic skeleton applied to a Rogowski coil current transformer, and the steps are as follows:

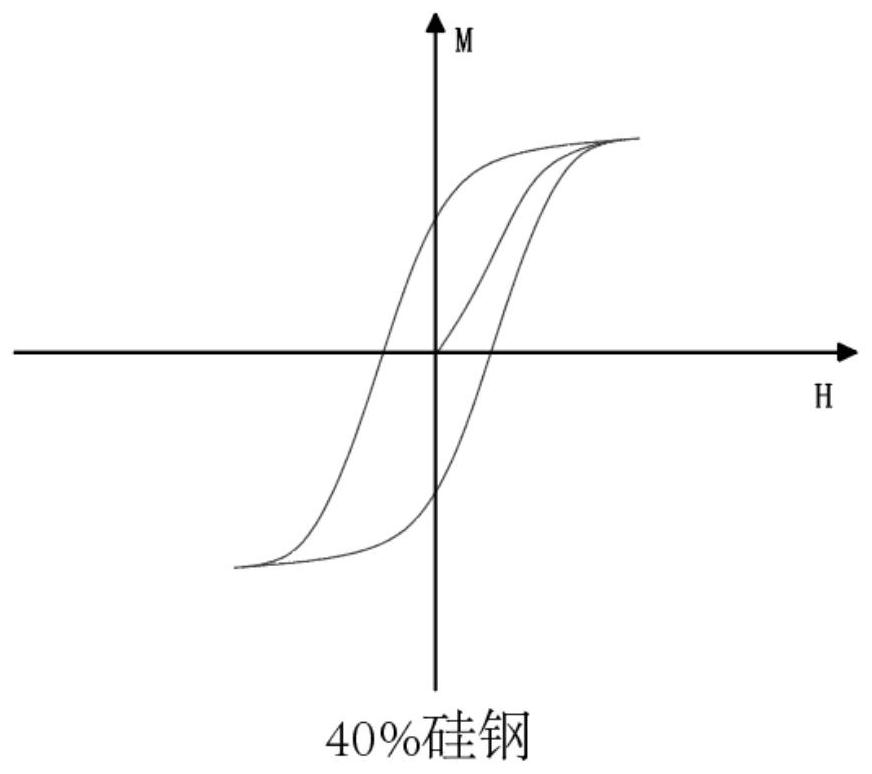

[0037] Dissolve 2g of silane coupling agent (KH-550) in 200ml of ethanol (solvent), stir evenly, add 1000g of silicon steel powder and mix well, then remove the solvent to complete the surface pretreatment of silicon steel powder; Surface pretreatment is carried out to make the surface of silicon steel powder change from hydrophilic to hydrophobic, so that it can be evenly dispersed into the light-cured resin to form a material with uniform internal magnetic permeability; silicon steel has a high magnetic permeability of weak magnetic field, and its magnetic permeability The ratio is 7000-10000, and the saturation magnetic induction is about 2T; the coupling agent is silane-based KH-550, KH-550 is an amino functional silane, which is alkaline, soluble in organic solvents and water, and is...

Embodiment 2

[0043] The difference between this embodiment and embodiment 1 is that the mixing ratio of silicon steel powder, photocurable resin and additives is 20%:77%:3%.

Embodiment 3

[0048] The difference between this embodiment and the embodiment 1 lies in that the permalloy powder is used as the soft ferromagnetic material to prepare the magnetic skeleton applied to the iron core coil current transformer.

[0049] Dissolve 2g of silane coupling agent (KH-550) in 200ml of ethanol, stir evenly, add 1000g of permalloy powder and mix well, then volatilize the ethanol to complete the surface pretreatment of permalloy powder; As a very high weak magnetic field permeability, the permeability is 20000-200000, and the saturation magnetic induction is about 1T;

[0050] Mix the surface-pretreated permalloy powder with light-curing resin and additives at a ratio of 30%: 69%: 1%;

[0051] According to the size and shape of the required magnetic skeleton, use 3D modeling software for 3D modeling to build a 3D model of a square ring magnetic skeleton. The cross section of the magnetic skeleton is a square with a side length of 10mm, and the square side length inside t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Residual magnetization | aaaaa | aaaaa |

| Saturation magnetic induction | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com