Modified desulfurized fly ash for fixing carbon dioxide and preparation method thereof

A carbon dioxide and desulfurization ash technology, applied in the direction of organic chemical methods, chemical instruments and methods, separation methods, etc., can solve the problems of poor carbon fixation ability and low calcium element content, and achieve improved capacity, convenient operation, and simple and easy preparation method line effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

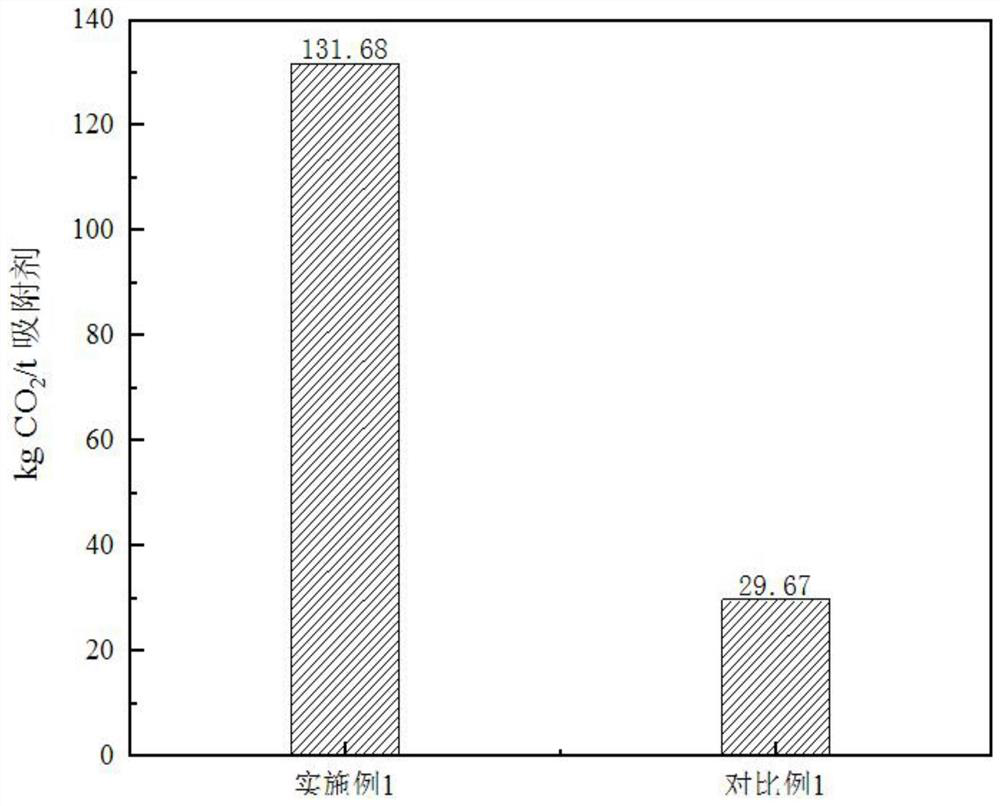

Embodiment 1

[0029] A method for preparing a modified desulfurization ash for fixing carbon dioxide, comprising the following steps:

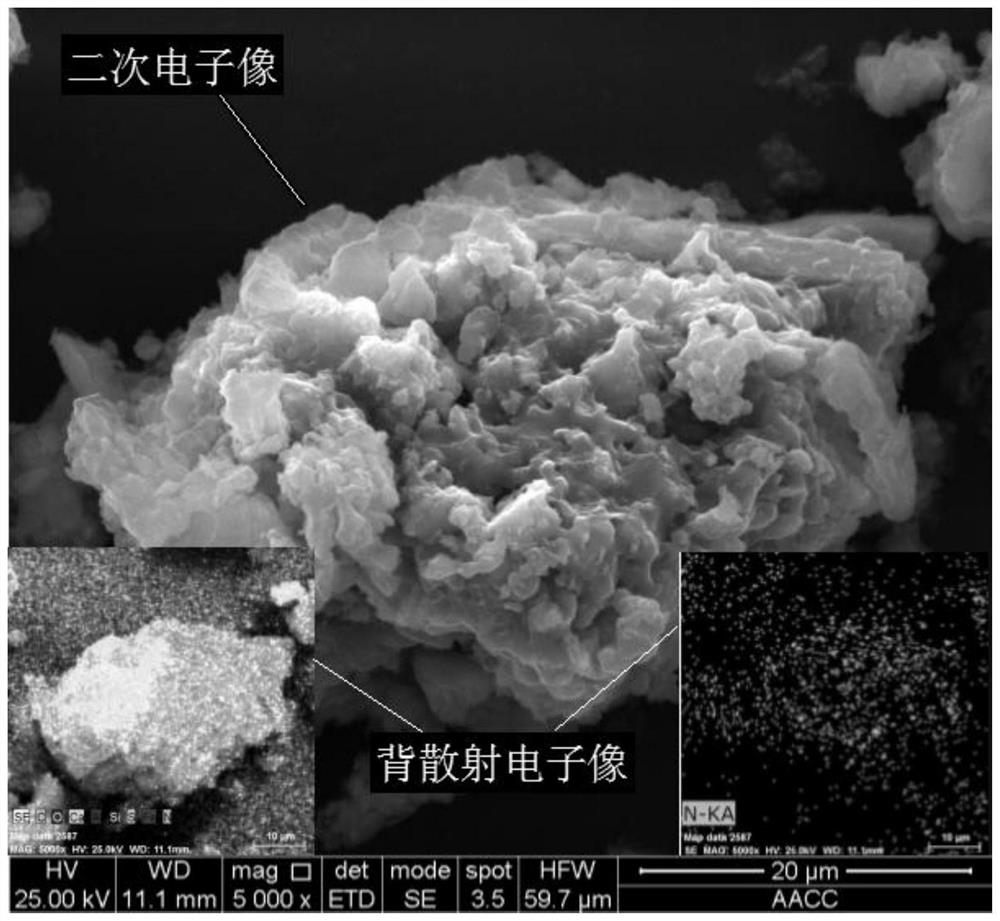

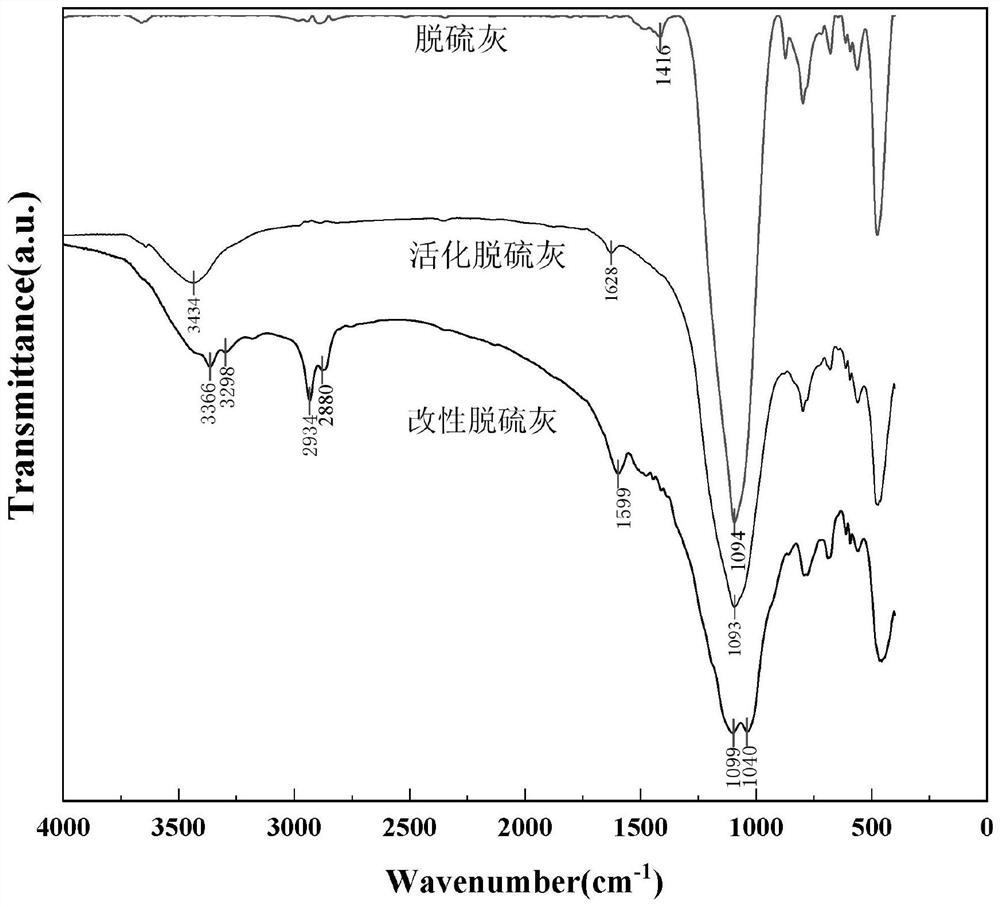

[0030] (1) Take 50 grams of desulfurization ashes, wash them twice with ethanol and deionized water, dry them in a drying oven at 105°C until they pass through a 100-mesh sieve with a constant weight, and heat them at 800°C for 2 hours in a muffle furnace to obtain activated desulfurization Ash;

[0031] (2) Take 50 grams of γ-aminopropyltriethoxysilane and dissolve it in 25 grams of absolute ethanol, then add 50 grams of deionized water, and treat it for 30 hours at 40°C, with an ultrasonic power of 400W and a frequency of 40kHz. Minutes, get nitrogen-containing silane coupling agent hydrolyzate;

[0032] (3) The activated desulfurization ash obtained in step (1) was mixed with the nitrogen-containing silane coupling agent hydrolyzate obtained in step (2), mechanically stirred at a speed of 250 rpm for 4 hours, and the product was tiled on a glass plate, ...

Embodiment 2

[0046] A method for preparing a modified desulfurization ash for fixing carbon dioxide, comprising the following steps:

[0047](1) Take 40 grams of desulfurization ashes, wash them twice with ethanol and deionized water, dry them in a drying oven at 100°C until they pass through a 200-mesh sieve with a constant weight, and heat them at 700°C for 1.5 hours in a muffle furnace to obtain activated desulfurization Ash;

[0048] (2) Dissolve 30 grams of γ-aminopropyltrimethoxysilane in 20 grams of absolute ethanol, then add 20 grams of deionized water, and stir mechanically at 40°C for 1 hour to obtain a nitrogen-containing silane coupling agent for hydrolysis liquid;

[0049] (3) The activated desulfurization ash obtained in step (1) was mixed with the nitrogen-containing silane coupling agent hydrolyzate obtained in step (2), mechanically stirred at a speed of 300 rpm for 4 hours, and the product was tiled on a glass plate, Dry naturally in the air until the solvent evaporates...

Embodiment 3

[0055] A method for preparing a modified desulfurization ash for fixing carbon dioxide, comprising the following steps:

[0056] (1) Take 40 grams of desulfurization ashes, wash them twice with ethanol and deionized water, dry them in a drying oven at 105°C until they pass through a 300-mesh sieve with a constant weight, and heat them at 750°C for 2 hours in a muffle furnace to obtain activated desulfurization Ash;

[0057] (2) Dissolve 60 grams of γ-aminopropylmethyldiethoxysilane in 50 grams of absolute ethanol, then add 80 grams of deionized water, and stir mechanically at 40°C for 2 hours to obtain nitrogen-containing silane diacetate Joint agent hydrolyzate;

[0058] (3) The activated desulfurization ash obtained in step (1) was mixed with the nitrogen-containing silane coupling agent hydrolyzate obtained in step (2), mechanically stirred at a speed of 350 rpm for 4 hours, and the product was tiled on a glass plate, Dry naturally in the air until the solvent evaporates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com