Preparation method of green functional clay repair material for combined pollution

A technology for composite pollution and repair materials, applied in the field of preparation of green functional clay repair materials, can solve the problems of high cost, inability to guarantee adsorption performance, etc., and achieve the effects of low cost, simple preparation method and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

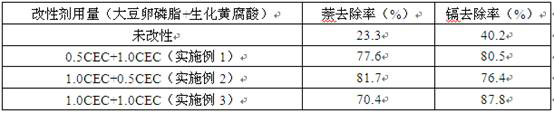

Examples

preparation example Construction

[0024] A preparation method for a green functional clay restoration material for complex pollution, comprising the steps of:

[0025] The first step is to mix the clay minerals that have been purified by water and remove impurities with water in proportion, and stir evenly to obtain a suspension, then add an absolute ethanol solution containing soybean lecithin in proportion to obtain a mixed solution, and adjust the pH of the mixed solution It is acidic. After ultrasonication for 15 minutes, shake at a constant temperature of 40°C for 24 hours, centrifuge, wash and dry to obtain lecithin-modified clay;

[0026] The second step is to mix the lecithin modified clay with water in proportion, stir evenly to obtain a suspension, add an aqueous solution containing biochemical fulvic acid in proportion to obtain a mixed solution, shake at a constant temperature of 25°C for 24 hours, centrifuge and wash dried, ground and passed through a 200-mesh sieve to obtain lecithin-biochemical ...

Embodiment 1

[0028] Take 1 g of washed and purified sodium-based bentonite and add it to 80 mL of aqueous solution to make a suspension, add 20 mL of soybean lecithin anhydrous ethanol solution with a modification ratio of 0.5 (containing 0.3654 g of soybean lecithin), and use 0.1mol L -1 HNO 3 The solution adjusted the pH of the mixed solution to 2.29, then the mixed solution was ultrasonicated for 15 minutes, then oscillated on a constant temperature oscillator at 40°C and 180rpm for 24h, and then centrifuged, and the clay was washed with absolute ethanol and deionized water for 5 times in sequence, and finally vacuum-dried at 60°C for 12 hours To obtain lecithin-modified clay; then add the prepared lecithin-modified clay to 20mL aqueous solution to make a suspension, and then add 20mL biochemical fulvic acid aqueous solution with a modification ratio of 1.0 (containing 0.2973g biochemical fulvic acid) , the mixed solution was shaken on a constant temperature oscillator at 25°C and 180rp...

Embodiment 2

[0030]Take 1 g of washed and purified sodium-based bentonite and add it to 80 mL of aqueous solution to make a suspension, add 20 mL of soybean lecithin anhydrous ethanol solution with a modification ratio of 1.0 (containing 0.7308 g of soybean lecithin), and use 0.1mol L -1 HNO 3 The solution adjusted the pH of the mixed solution to 2.30, then the mixed solution was ultrasonicated for 15 minutes, then oscillated on a constant temperature oscillator at 40°C and 180rpm for 24h, and then centrifuged, and the clay was washed with absolute ethanol and deionized water for 5 times in sequence, and finally vacuum-dried at 60°C for 12 hours To obtain lecithin-modified clay; then add the prepared lecithin-modified clay to 20mL aqueous solution to make a suspension, add 20mL biochemical fulvic acid aqueous solution with a modification ratio of 0.5 (containing 0.1487g of biochemical fulvic acid), The mixture was oscillated on a constant temperature oscillator at 25°C and 180rpm for 24 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com