Scrap removing device for mechanical drilling machine

A mechanical drilling and chip cleaning technology, which is applied in the field of machine tools, can solve problems such as material wear and drilling effects, and achieve the effects of improving stability, smooth rotation, and preventing shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

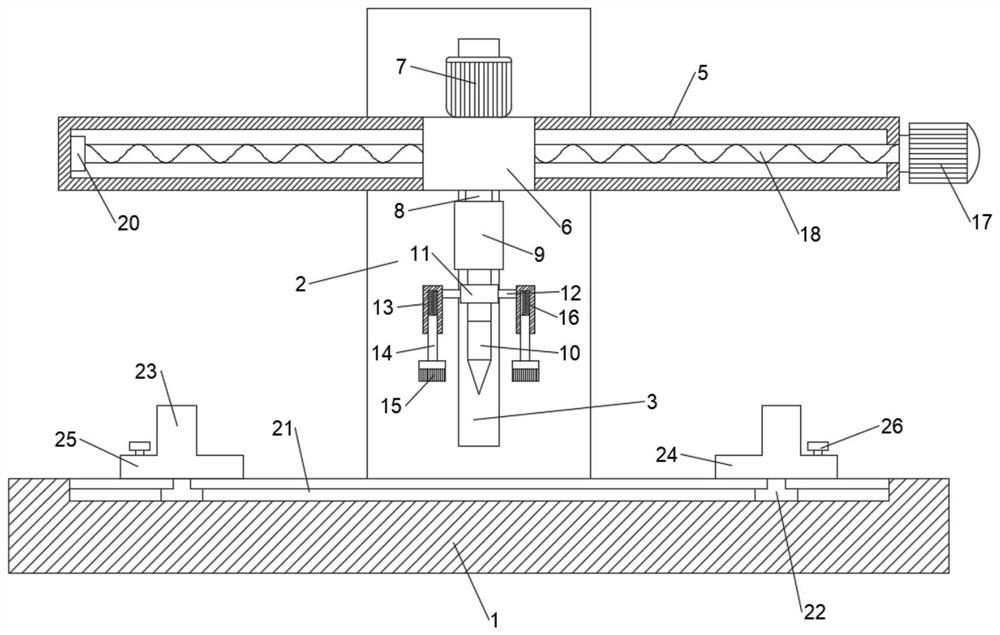

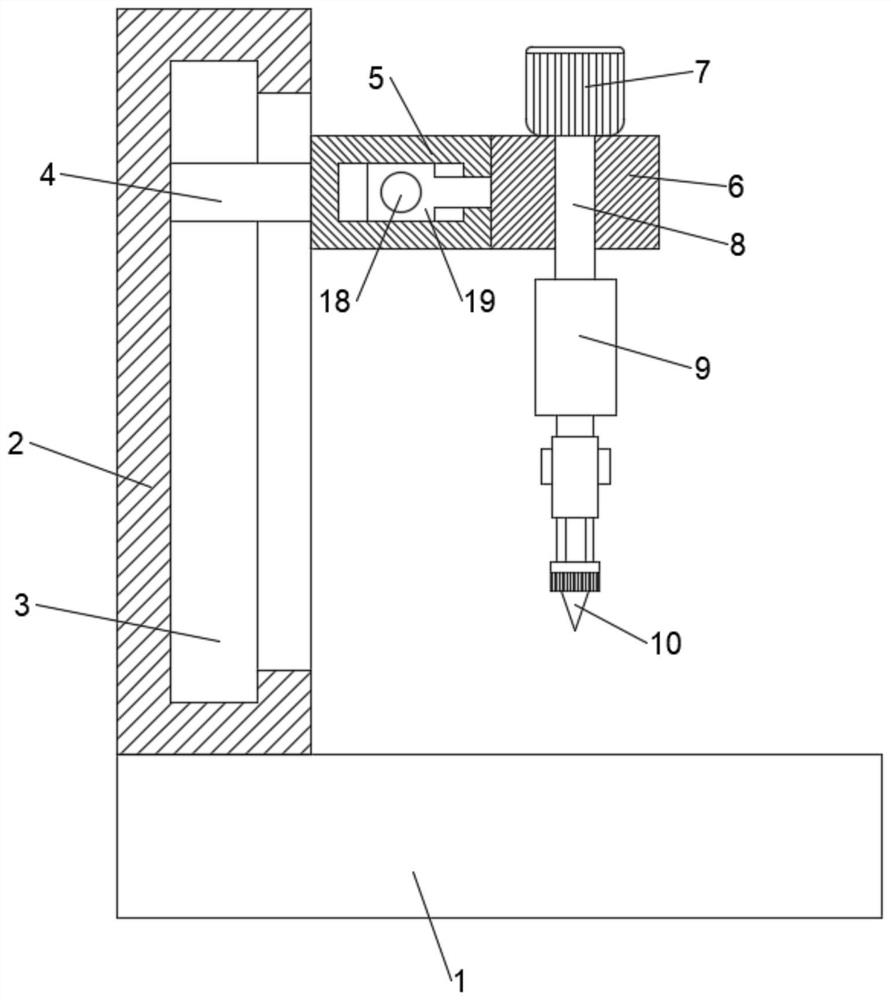

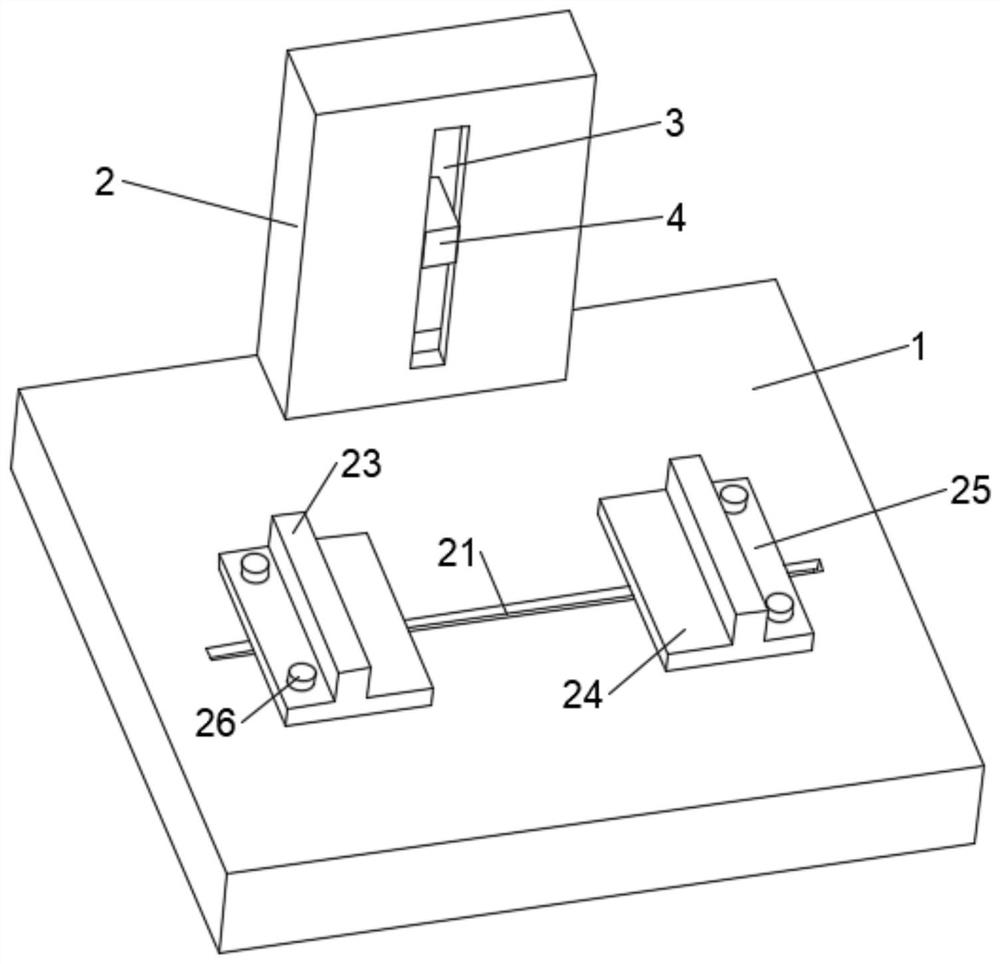

[0021] see Figure 1-3 , in an embodiment of the present invention, a chip cleaning device for a mechanical drilling machine includes a base 1, a bracket 2 is arranged on the upper end of the base 1, a groove 3 is arranged on the side wall of the bracket 2, and an electric slide is installed in the groove 3. block 4, the electric slider 4 is fixedly connected with a square frame 5, a mobile device is arranged in the square frame 5, the mobile device is fixedly connected with a connection seat 6, and the upper end of the connection seat 6 is provided with a motor one 7, and the output end of the motor one 7 is fixed A shaft rod 8 is connected, the shaft rod 8 runs through the connecting seat 6 and the lower end is fixedly connected with a telescopic rod 9, the end of the telescopic rod 9 is provided with a drill bit 10, and the side wall at the end of the telescopic rod 9 is provided with a chip removal device. 4 slide up and down in the groove 3 to adjust the height of the squ...

Embodiment 2

[0027] In order to improve the stability of the rotation of the screw 18, this embodiment is further improved on the basis of Embodiment 1. The improvement is: a shaft sleeve 20 is arranged on the inner left wall of the square frame 5, and the left end of the screw 18 is rotatably connected to the Inside the shaft sleeve 20, the stability of the screw rod 18 can be improved through the shaft sleeve 20, so that it can rotate more smoothly.

[0028] The working principle of this embodiment is: in order to improve the stability of the rotation of the screw rod 18, a shaft sleeve 20 is arranged on the inner left side wall of the square frame 5, and the left end of the screw rod 18 is connected in the shaft sleeve 20 in rotation, through the shaft sleeve 20 , can improve the stability of the screw rod 18, so that it can rotate more smoothly.

[0029]To sum up, by setting the chip removal device, the telescopic rod 9 also drives the chip removal device to rotate, and removes the deb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com