TIG welding method for low-activation martensitic steel

A technology of martensitic steel and welding methods, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of easy generation of pores and microcracks, poor weldability, etc., and achieve smooth and beautiful macroscopic appearance and good shape , the effect of high arc column temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

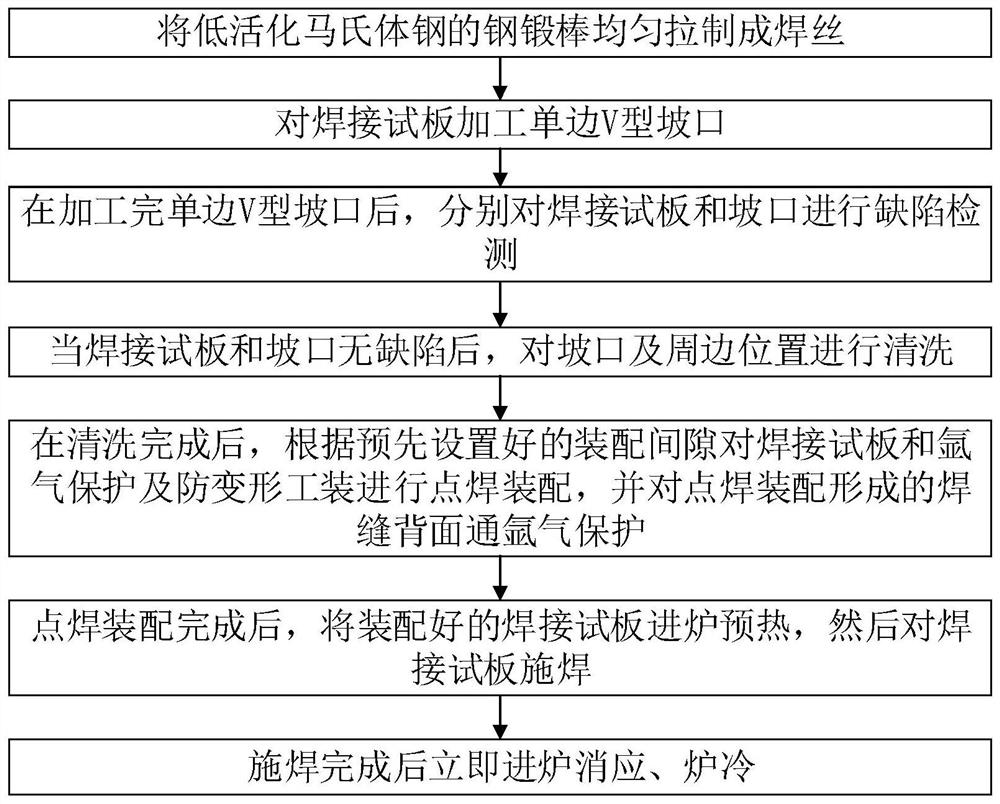

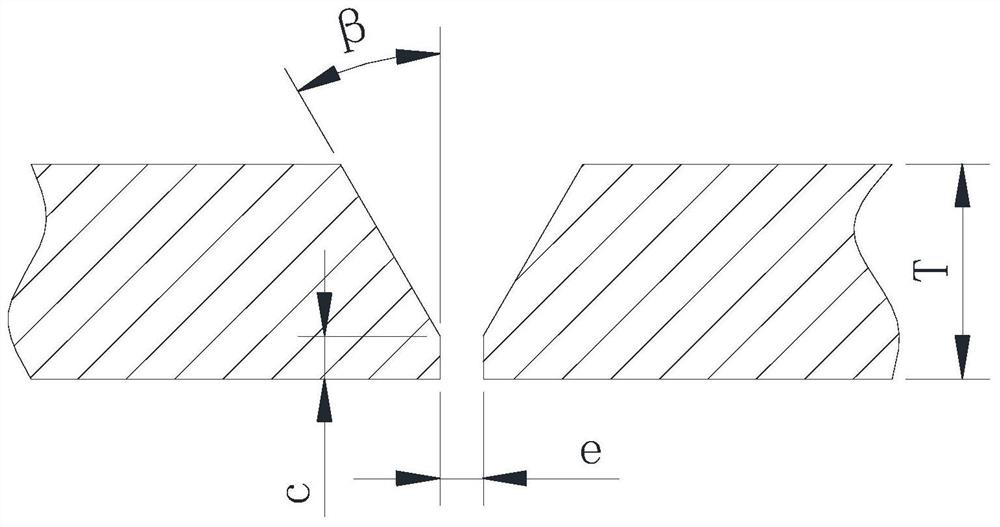

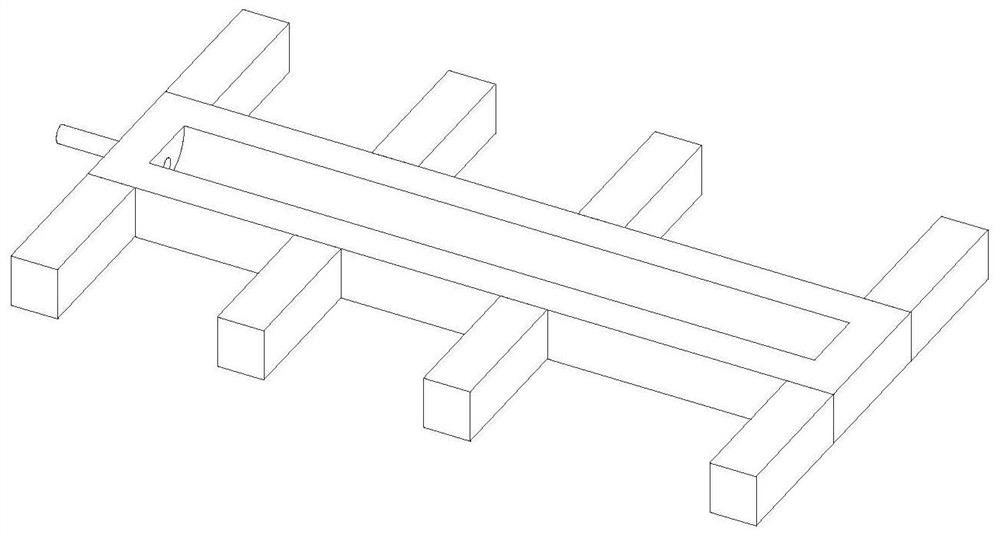

[0031] Such as Figure 1-Figure 5 As shown, this embodiment takes the low-activation martensitic CLF-1 steel welding test plate 1 of 2mm*200mm*500mm as an example for illustration: first, the low-activation martensitic CLF-1 steel forged rod is drawn into a diameter of Welding wire of 1.6mm; then machine the welding test plate 1 with a unilateral V-shaped groove β of 15° and blunt edge thickness c1mm; after the processing is completed, conduct UT (Ultrasonic Test) flaw detection on the welding test plate 1 , carry out PT (penetration testing, penetration testing) flaw detection on the groove surface. When the test plate and the groove surface are qualified, use acetone to clean the groove and the surrounding 1 times the thickness position and the surface of the welding wire. Oxide film to maintain metallic luster; after cleaning, according to the pre-set 1mm assembly gap e, perform spot welding assembly on welding test plate 1 and argon protection and anti-deformation tooling ...

Embodiment 2

[0034] Such as Figure 1-Figure 5As shown, this embodiment takes the low-activation martensitic CLF-1 steel welding test plate 1 of 10mm*200mm*500mm as an example for illustration: first, the low-activation martensitic CLF-1 steel forged rod is drawn into a diameter of Welding wire of 2.0 mm; then machine the welding test plate 1 with a unilateral V-shaped groove β of 15° and blunt edge thickness c1 mm; after the processing is completed, conduct UT (Ultrasonic Test) flaw detection on the welding test plate 1 , carry out PT (penetration testing, penetration testing) flaw detection on the groove surface. When the test plate and the groove surface are qualified, use acetone to clean the groove and the surrounding 1 times the thickness position and the surface of the welding wire. Oxide film to maintain metallic luster; after cleaning, according to the pre-set 2mm assembly gap e, perform spot welding assembly on welding test plate 1 and argon protection and anti-deformation toolin...

Embodiment 3

[0037] Such as Figure 1-Figure 5 As shown, this embodiment takes the low-activation martensitic CLF-1 steel welding test plate 1 of 20mm*200mm*500mm as an example for illustration: first, the low-activation martensitic CLF-1 steel forged rod is drawn into a diameter of Welding wire of Ф2.4mm; then, machine the welding test plate 1 with a unilateral V-groove β of 30° and blunt edge thickness c2mm; after the processing is completed, perform UT (Ultrasonic Test) on the welding test plate 1 Flaw detection: PT (penetration testing, penetration testing) flaw detection is carried out on the groove surface. When the test plate and the groove surface are qualified, use acetone to clean the groove and the surrounding 1 times the thickness and the oil stains and iron chips on the surface of the welding wire. and oxide film to keep the metallic luster; after the cleaning is completed, perform spot welding assembly on the welding test plate 1 and the argon protection and anti-deformation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com