Method and equipment for producing trimethylsilyl trifluoromethanesulfonate

A trimethylsilyl trifluoromethanesulfonate and production equipment technology, which is applied in the field of trimethylsilyl trifluoromethanesulfonate production, can solve the problems of violent reaction, insufficient reaction, and difficult control, and achieve stirring The effect of sufficient reaction, high purity and less impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

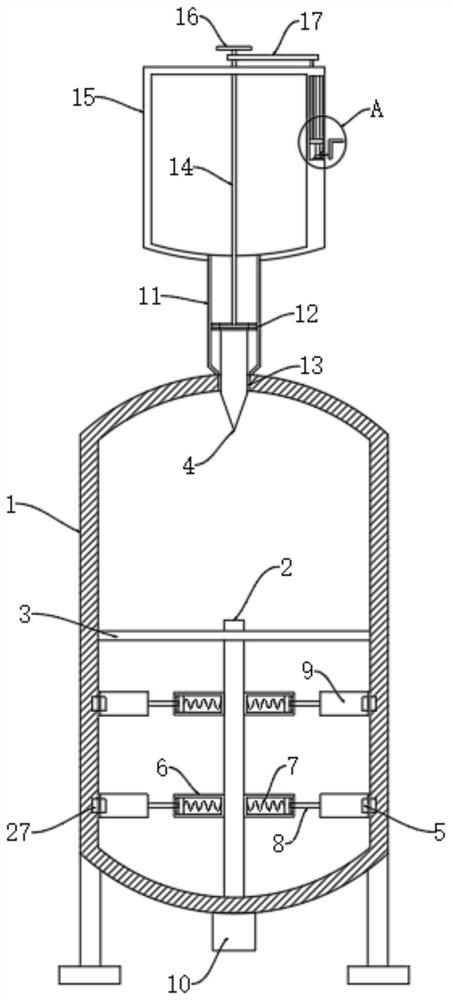

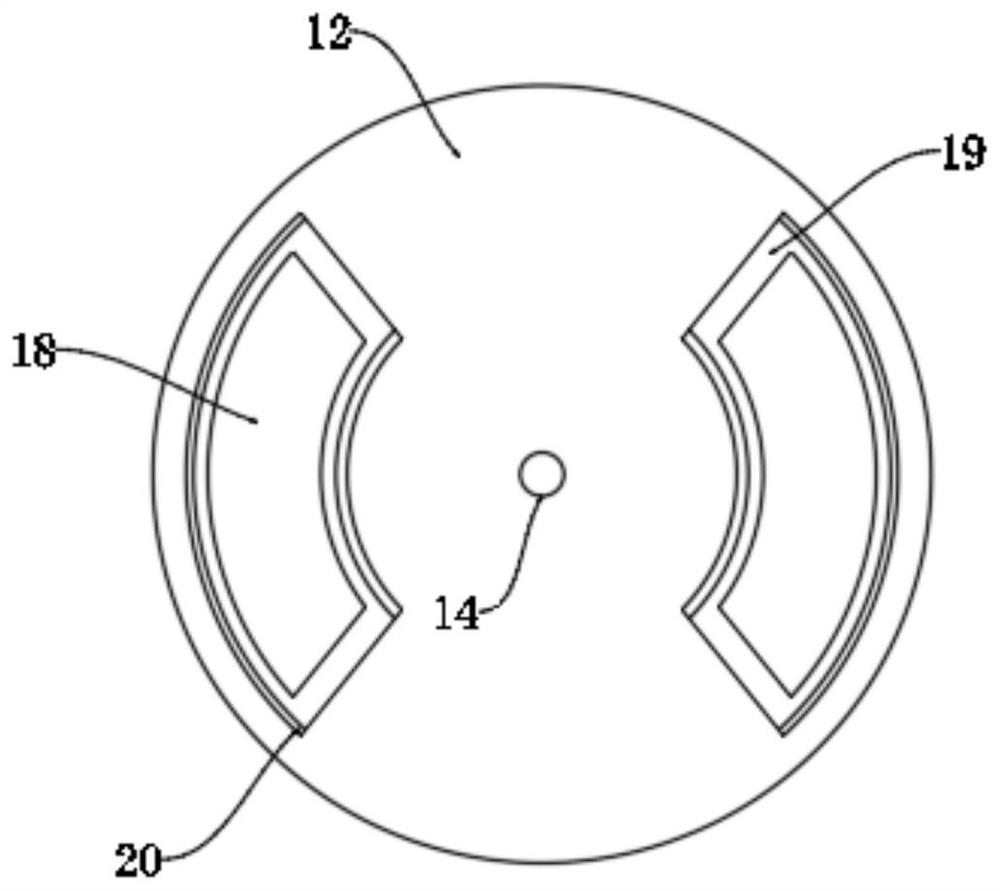

[0025] Such as Figure 1~3 As shown, a trimethylsilyl trifluoromethanesulfonate production equipment, the equipment includes a reactor 1 and a quantitative tank 15.

[0026] The middle part of the reaction kettle 1 is fixedly connected with the fixed plate 3, the top of the rotating rod 2 protrudes from the fixed plate 3 and is rotatably connected with the fixed plate 3, the bottom of the rotating rod 2 protrudes from the bottom of the reaction kettle 1, and is fixed to the outside of the bottom of the reaction kettle 1 The motor 10 is connected; the outer wall of the rotating rod 2 is provided with two sets of symmetrical stirring mechanisms.

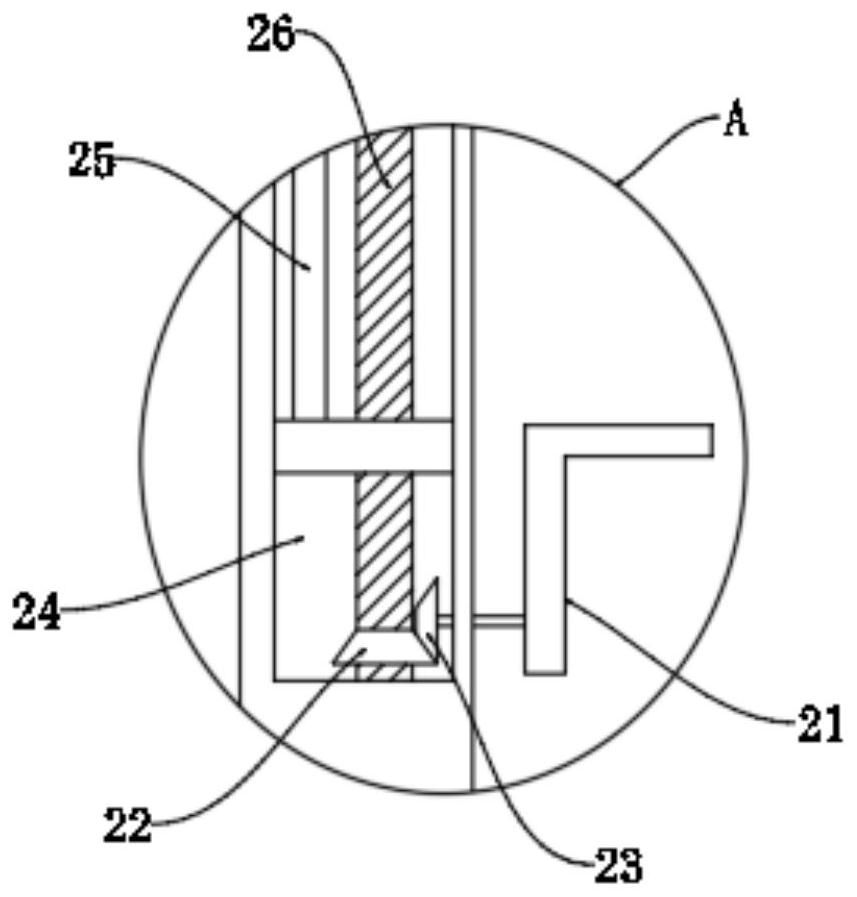

[0027] Each group of stirring mechanisms includes a device cylinder 6 fixed on the outer wall of the rotating rod 2. There are four device cylinders 6, and every two are symmetrically placed as a group, and the two groups are arranged up and down; The inner wall of the plate and the inner wall of the device cylinder 6 are elastically ...

Embodiment 2

[0033] A method for producing trimethylsilyl trifluoromethanesulfonate, the method steps are as follows:

[0034]Add trifluoromethanesulfonic acid in reactor 1, add trimethylchlorosilane dropwise in reactor 1 to react, the rate of addition is 5mm / min, the pressure of reactor 1 is 0.002MPa, and the reaction temperature is 20°C. The time was 8.5 hours; after the reaction was completed, distillation under reduced pressure was carried out, and the fraction at 125°C was collected to obtain the final product, trimethylsilyl trifluoromethanesulfonate, with a yield of 98.1%.

[0035] The final product that present embodiment is made detects as follows:

[0036] It can be known that the final product is trimethylsilyl trifluoromethanesulfonate with a purity of 99.97% through Fourier transform infrared spectroscopy and nuclear magnetic resonance detection.

Embodiment 3

[0038] A method for producing trimethylsilyl trifluoromethanesulfonate, the method steps are as follows:

[0039] Add trifluoromethanesulfonic acid in reactor 1, drop trimethylchlorosilane in reactor 1 to react, the rate of addition is 8mm / min, the pressure of reactor 1 is 0.002MPa, and the reaction temperature is 25°C. The time was 9 hours; after the reaction was completed, the reaction was distilled under reduced pressure, and the fraction at 130°C was collected to obtain the final product, trimethylsilyl trifluoromethanesulfonate, with a yield of 98.3%.

[0040] The final product that present embodiment is made detects as follows:

[0041] It can be known that the final product is trimethylsilyl trifluoromethanesulfonate with a purity of 99.98% through Fourier transform infrared spectroscopy and nuclear magnetic resonance detection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com