Active functional polymer and preparation method and application thereof

A polymer and functional technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of flooding and plugging agents that cannot meet the requirements of flooding and plugging, and improve surface activity, Effect of improving polymerization activity, excellent thickening and emulsifying oil washing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

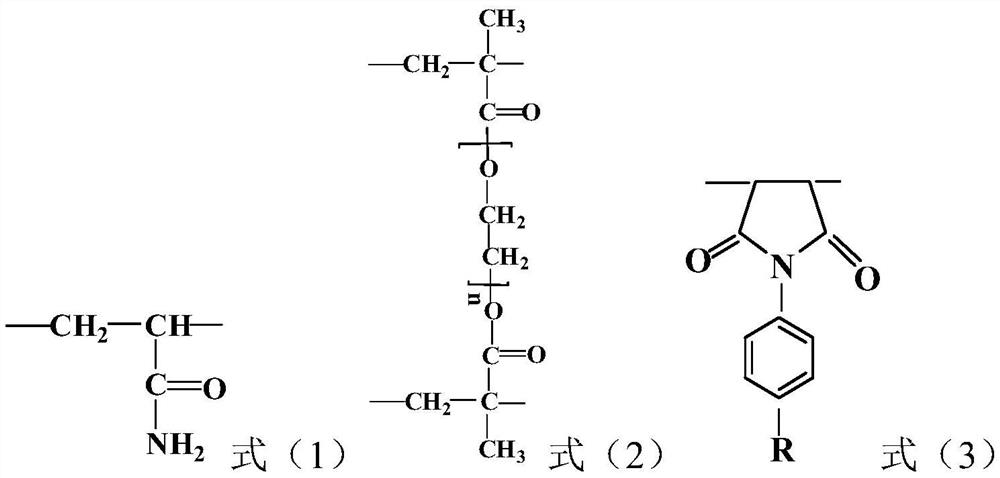

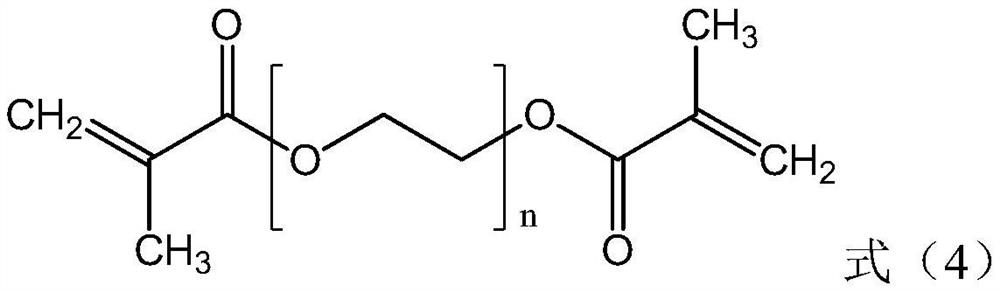

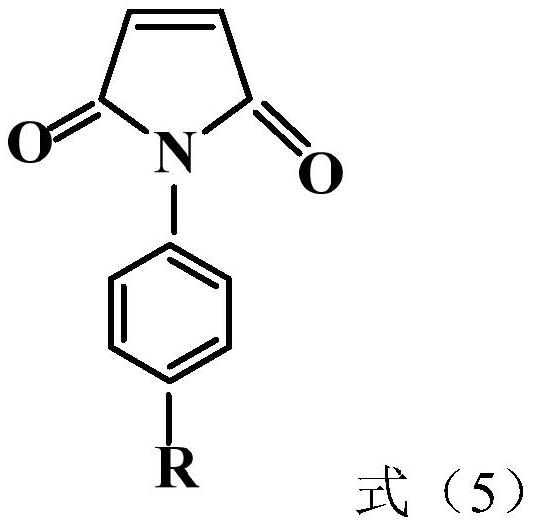

Method used

Image

Examples

Embodiment 1

[0095]1. Add 25.5g of acrylamide (mass content 85%) into an insulated polymerization reaction bottle (ie, a polymerization bottle), add 70g of deionized water to dissolve and make an aqueous solution, and then add sodium hydroxide to adjust the pH to 6;

[0096] 2. Add 1.5g functional monomer X (mass content 5%), 3g functional monomer Y1 (mass content 10%), emulsifier 0.25g, 1% EDTA-2Na aqueous solution 1g, urea 1g, pentamethyl di Ethylenetriamine 280mg, fully stirred to form stable micelles;

[0097] 3. Control the temperature of the aqueous solution at 20°C. After 30 minutes of blowing nitrogen to drive oxygen, add 2.5g of 0.2% potassium persulfate aqueous solution and 2.5g of 0.1% sodium bisulfite aqueous solution to initiate the reaction, and continue to pass nitrogen for 5 minutes. Stop, polymerize for 8 hours after sealing;

[0098] 4. Take out the rubber block, add 0.4g granulated alkali after granulation, mix evenly, and then carry out hydrolysis at 80°C for 3 hours; ...

Embodiment 2

[0102] 1. Add 28.5g of acrylamide (mass content 95%) into an insulated polymerization reaction bottle (that is, a polymerization bottle), add 70g of deionized water to dissolve and make an aqueous solution, and then add sodium hydroxide to adjust the pH to 10.0;

[0103] 2, add 0.15g functional monomer X (mass content 0.5%) successively, 1.35g functional monomer Y2 (mass content 4.5%), emulsifier 0.2g, 1% EDTA-2Na aqueous solution 2.0g, urea 0.5g, five Methyldiethylenetriamine 60.0mg, fully stirred to form stable micelles;

[0104] 3. Control the temperature of the aqueous solution at 25°C. After 30 minutes of blowing nitrogen to drive oxygen, add 4 g of 0.2% potassium persulfate aqueous solution and 4 g of 0.1% sodium bisulfite aqueous solution to initiate the reaction, and continue to pass nitrogen for five minutes before stopping. Polymerization after sealing for 9.5 hours;

[0105] 4. Take out the rubber block, add 0.6g granulated alkali after granulation, mix evenly, and...

Embodiment 3

[0109] 1. Add 27.6g of acrylamide (mass content 92%) into an insulated polymerization reaction bottle (ie, a polymerization bottle), add 70g of deionized water to dissolve and make an aqueous solution, and then add sodium hydroxide to adjust the pH to 7.2;

[0110] 2. Add 0.75g functional monomer X (mass content 3%), 1.5g functional monomer Y3 (mass content 5%), emulsifier 0.3g, 1% EDTA-2Na aqueous solution 2g, urea 1.5g, pentagram Diethylenetriamine 200mg, fully stirred to become stable micelles;

[0111] 3. Control the temperature of the aqueous solution at 25°C. After 30 minutes of blowing nitrogen to drive oxygen, add 6.5g of 0.2% potassium persulfate aqueous solution and 6.5g of 0.1% sodium bisulfite aqueous solution to initiate the reaction, and continue blowing nitrogen for 5 minutes Stop, polymerize for 10 hours after sealing;

[0112] 4. Take out the rubber block, add 0.5g granulated alkali after granulation, mix evenly, and then carry out hydrolysis at 85°C for 3.0 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent viscosity | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

| Interfacial tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com