Extruder

An extruder and integrated technology, applied in slaughtering, meat processing equipment, food science, etc., can solve problems such as difficult cleaning operations, high damping pressure, and affecting continuous supply operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

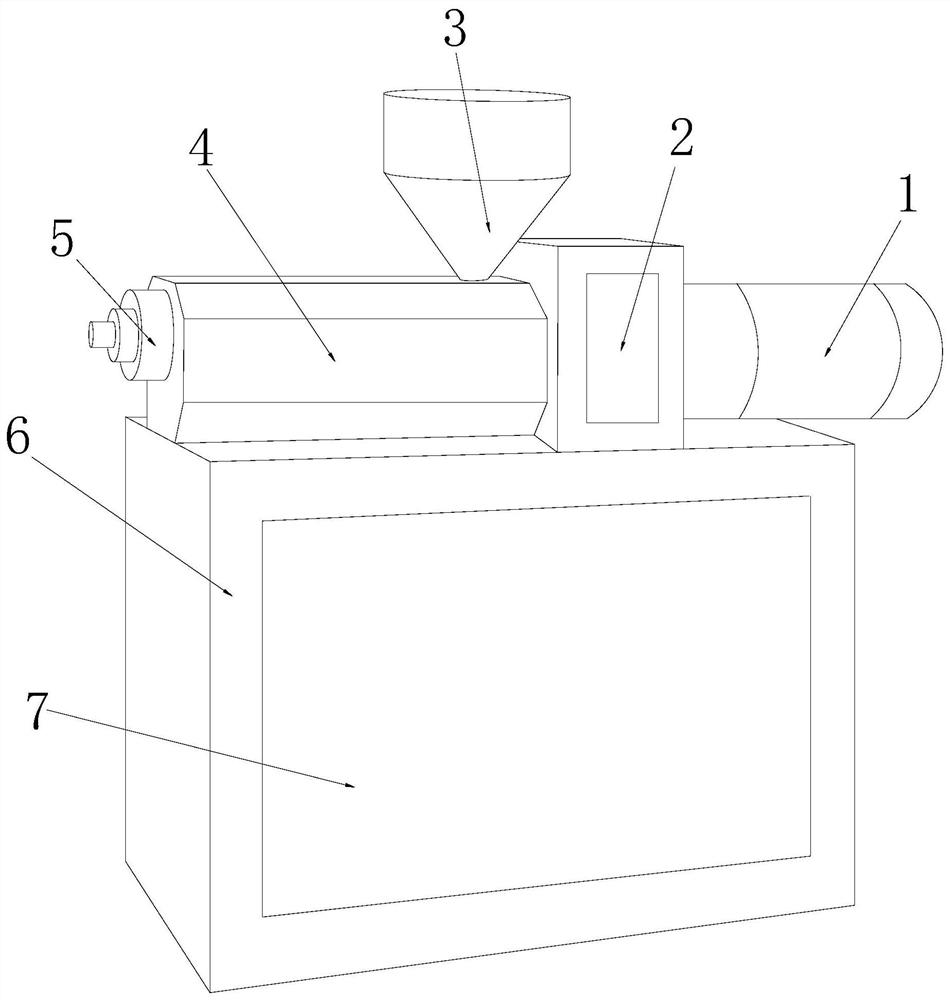

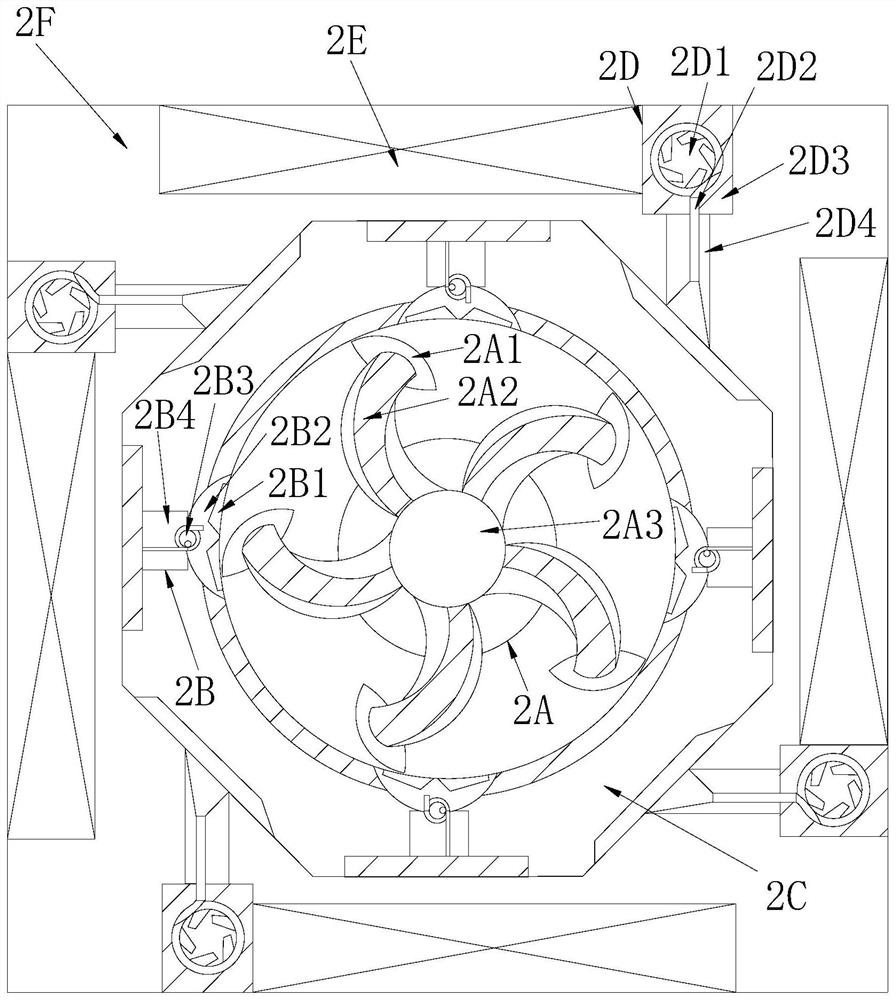

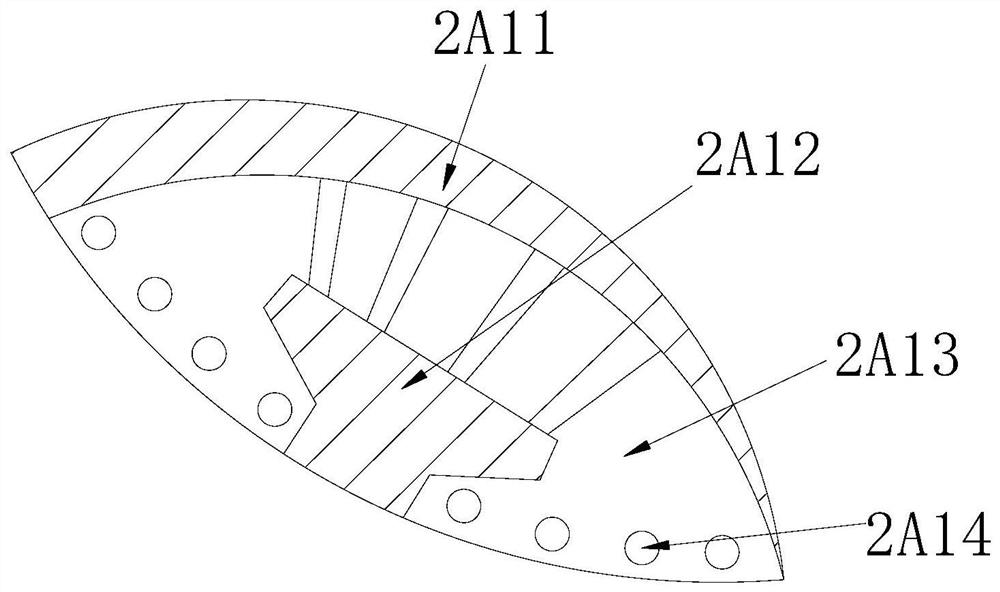

[0032] see Figure 1-Figure 6, the present invention provides an extruder, the structure of which includes: a shaft motor 1, a square cylinder shaving oil sleeve 2, a feed beam cylinder groove 3, a single spiral horizontal groove 4, a bearing seat 5, a base case shell 6, a storage The square box 7, the square cylinder shaving oil sleeve seat 2 is nested on the left side of the shaft motor 1 and the axes are collinear, and the feeding beam cylinder groove 3 is inserted in the upper right corner of the single helical horizontal groove 4 and mutually Vertical, the single helical horizontal groove 4 is installed on the left side of the square cylinder shaving oil sleeve 2 and communicates with each other, the single helical horizontal groove 4 is mechanically connected with the bearing seat 5 and the axes are collinear, and the base box shell 6 Nested together with the storage square box 7 and on the same vertical plane, the single helical horizontal groove 4 and the shaft motor 1...

Embodiment 2

[0039] see Figure 1-Figure 6 , the present invention provides a kind of extruder, other respects are identical with embodiment 1, and difference is:

[0040] see figure 2 , the oil sucking rod cylinder 2D is composed of a rotary brush cylinder 2D1, a funnel oil tube 2D2, a shell square cylinder 2D3, and an oil-absorbing paper rod tube 2D4, and the funnel oil tube 2D2 is inserted into the inside of the oil-absorbing paper rod tube 2D4. The rotary brush ball cylinder 2D1 is installed inside the shell square cylinder 2D3, the shell shell square cylinder 2D3 and the oil-absorbing paper rod tube 2D4 are fastened together and communicate with each other, and oil is drawn into the rotary brush ball cylinder 2D1 through the funnel oil pipe 2D2 to form The compression and density of the oil block are collected into blocks to store the effect, the oil film extension surface is reduced, and the rotary operation of the propeller of the anti-interference equipment is achieved.

[0041]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com