Process of producing monoterpenes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0087]The present invention will now be further described with reference to the following figures which show:

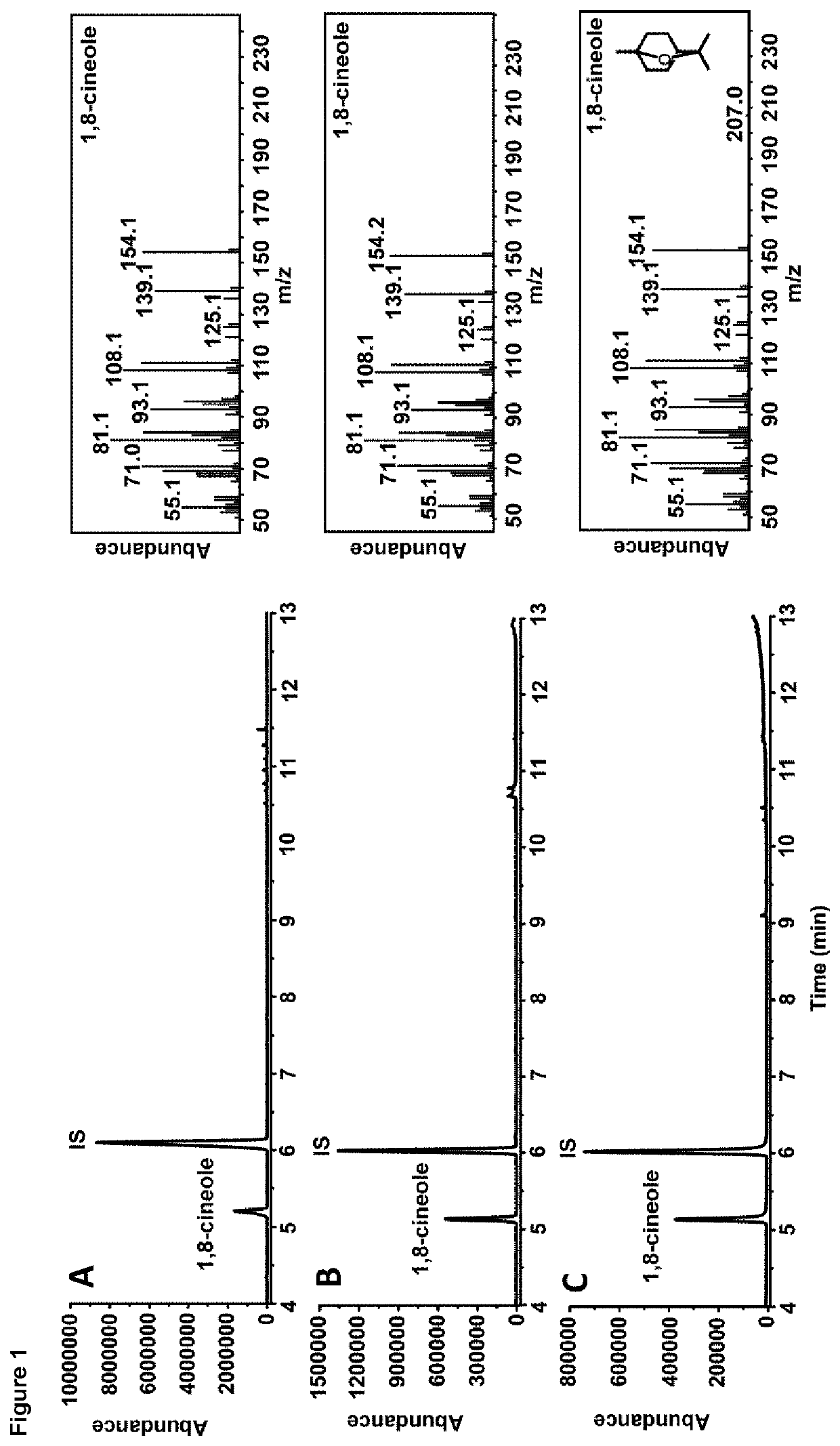

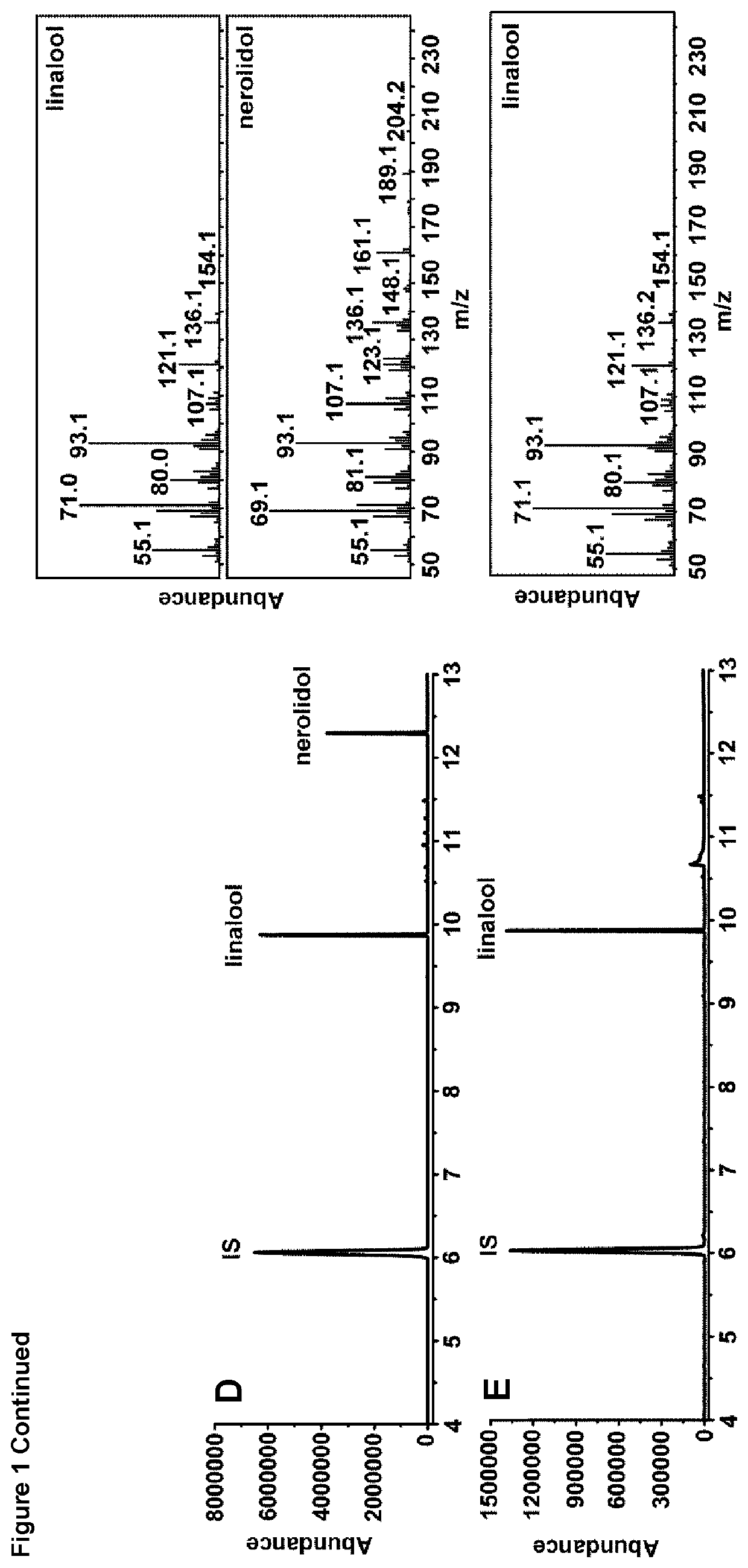

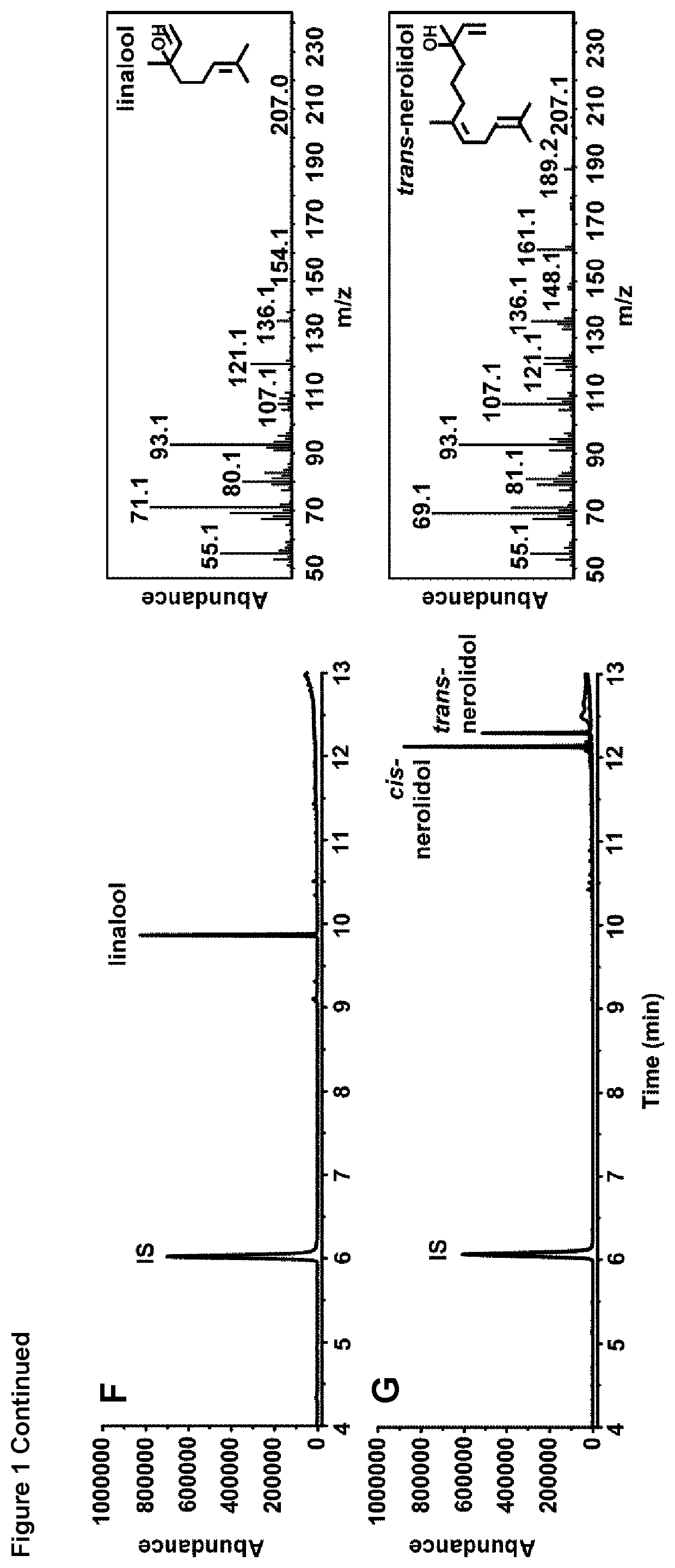

[0088]FIG. 1: GC-MS analysis using bacterial 1,8-cineole synthase (bCinS) and bacterial linalool synthase (bLinS). A) bCinS platform product profile. B) bCinS conversion of GPP (20 mM). C) 1,8-cineole standard (0.1 mg / ml). D) bLinS platform product profile. E) bLinS conversion of GPP (20 mM). F) R-linalool standard (0.1 mg / ml). G) cis- and trans-nerolidol standards (0.1 mg / ml). IS=internal standard (sec-butyl benzene).

[0089]FIG. 2: Structure of bCinS-FNPP complex. Superposition of plant cineole synthase (dark) and bCinS (light). The N-terminal and C-terminal domains of the plant CinS are labelled. An arrow indicates the conformational difference in the helix-break motif.

[0090]Materials and Methods

[0091]Expression and Purification of Bacterial 1, 8-Cineole Synthase (bCinS) and Bacterial Linalool Synthase (bLinS)

[0092]The full-length genes coding for 1,8-cineole synthase (WP_00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mass | aaaaa | aaaaa |

| Mass | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com