Plant-based mung bean protein yoghourt and preparation method thereof

A mung bean protein and mung bean-based technology, which is applied in dairy products, milk substitutes, applications, etc., can solve the problems of unrecognized functional properties of vegetable protein, and achieve rich amino acid types, stable and elastic gel structure, and fine and smooth texture. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

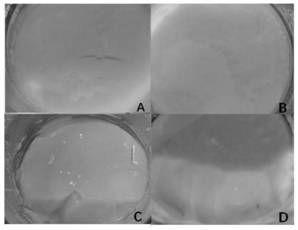

Image

Examples

Embodiment 1

[0040] Prepare a mung bean protein solution with a protein mass fraction of 1.5%, stir at room temperature for 30 minutes, place the completely dissolved mung bean protein solution under a high pressure of 200 MPa for three times, then adjust the pH to 12, react for 0.5 h, and then adjust the pH to be neutral. Continue to stir for 30 minutes; then add sucrose with a mass fraction of 8% to the uniformly stirred solution, and continue to stir until fully dissolved to obtain the fermentation base material; homogenize the fermentation base material twice at 150 MPa; The fermentation base material was sterilized by heating at 85°C for 15 minutes. After the fermentation base material was cooled to 35°C after sterilization, 1.0% bacterial powder was added under aseptic operation, shaken gently, and fermented at 43°C for 10 hours, then refrigerated After 12 hours of ripening, the plant-based plant-based mung bean protein yoghurt is obtained.

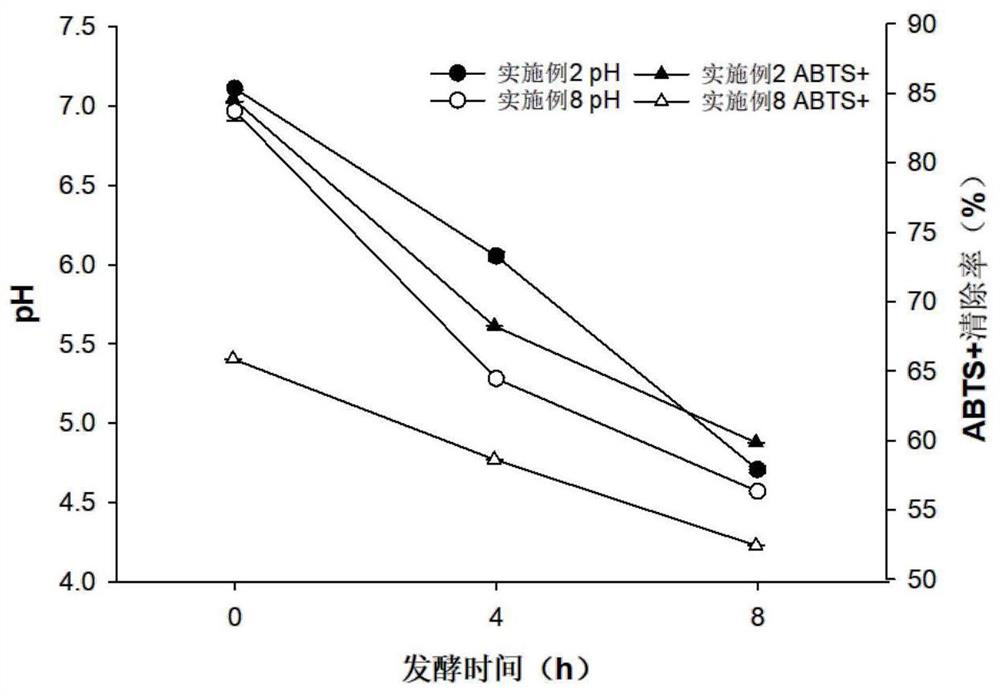

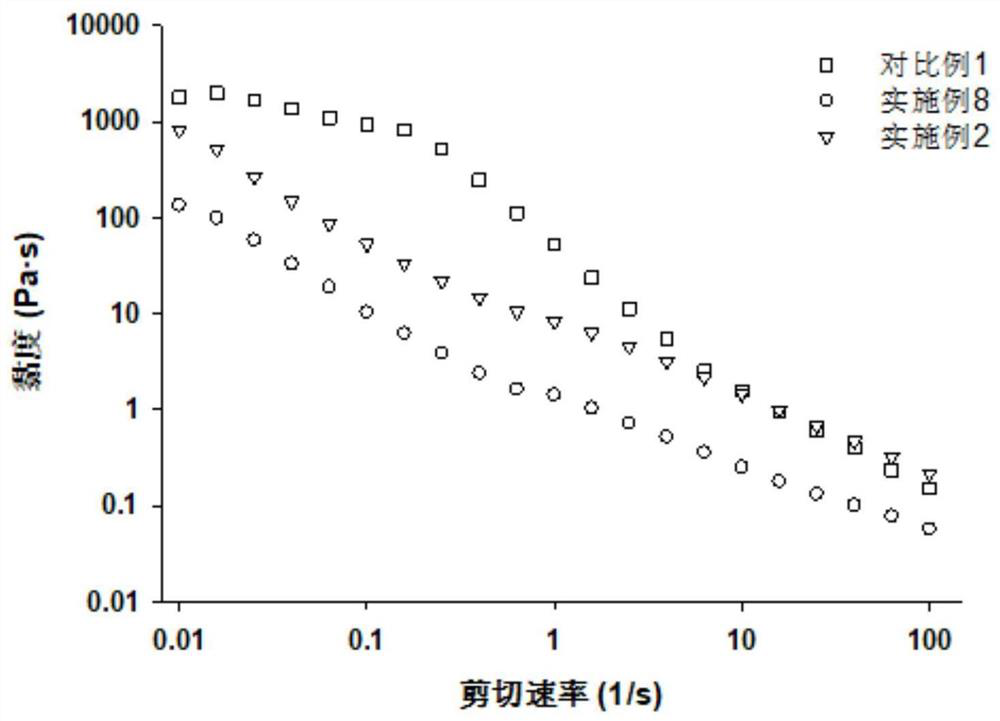

Embodiment 2

[0042] Prepare a mung bean protein solution with a protein mass fraction of 3.0%, stir at room temperature for 30 minutes, place the completely dissolved mung bean protein solution under 200MPa high pressure for three times, then adjust the pH to 12, react for 0.5h, and then adjust the pH to be neutral. Continue to stir for 30 minutes; then add sucrose with a mass fraction of 8% to the uniformly stirred solution, and continue to stir until fully dissolved to obtain the fermentation base material; homogenize the fermentation base material twice at 150 MPa; The fermentation base material was sterilized by heating at 85°C for 15 minutes. After the fermentation base material was cooled to 35°C after sterilization, 1.0% bacterial powder was added under aseptic operation, shaken gently, and fermented at 43°C for 10 hours, then refrigerated After 12 hours of ripening, the plant-based plant-based mung bean protein yoghurt is obtained.

Embodiment 3

[0044] Prepare a mung bean protein solution with a protein mass fraction of 4.0%, stir at room temperature for 30 minutes, place the completely dissolved mung bean protein solution under a high pressure of 200 MPa for three times, then adjust the pH to 12, react for 0.5 h, and then adjust the pH to be neutral. Continue to stir for 30 minutes; then add sucrose with a mass fraction of 8% to the uniformly stirred solution, and continue to stir until fully dissolved to obtain the fermentation base material; homogenize the fermentation base material twice at 150 MPa; The fermentation base material was sterilized by heating at 85°C for 15 minutes. After the fermentation base material was cooled to 35°C after sterilization, 1.0% bacterial powder was added under aseptic operation, shaken gently, and fermented at 43°C for 10 hours, then refrigerated After 12 hours of ripening, the plant-based plant-based mung bean protein yoghurt is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com