Beta-NaGdF4:Eu<3+> red fluorescent powder and preparation method thereof

A red phosphor, 3·6H2O technology, applied in chemical instruments and methods, luminescent materials, etc., can solve problems such as lack of preparation methods, and achieve the effects of simple operation method, high yield, excellent luminescence and paramagnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A kind of β-NaGdF provided by the present invention 4 : Eu 3+ A preparation method for red fluorescence, comprising the steps of:

[0034] (1) Gd(NO 3 ) 3 ·6H 2 O and Eu(NO 3 ) 3 ·6H 2 O in H at a molar ratio of 2:1 2 O, and stirred at a temperature of 10-50°C to obtain the first solution;

[0035] (2) adding an aqueous solution of L-lysine with a concentration of 0.001-50 mmol / mL to the first solution and mixing to obtain a second solution;

[0036] (3) NaCl and NH with a molar ratio of 1:8 4 F is added to the second solution and mixed to obtain a third solution with a large amount of precipitation;

[0037] (4) putting the third solution into a polytetrafluoroethylene reactor, and performing a hydrothermal reaction at a reaction temperature of 90-200° C. to obtain a fourth solution;

[0038] (5) After the fourth solution is filtered, washed and dried in sequence, β-NaGdF is obtained 4 : Eu 3+ sample;

[0039] Wherein, by controlling the concentration of ...

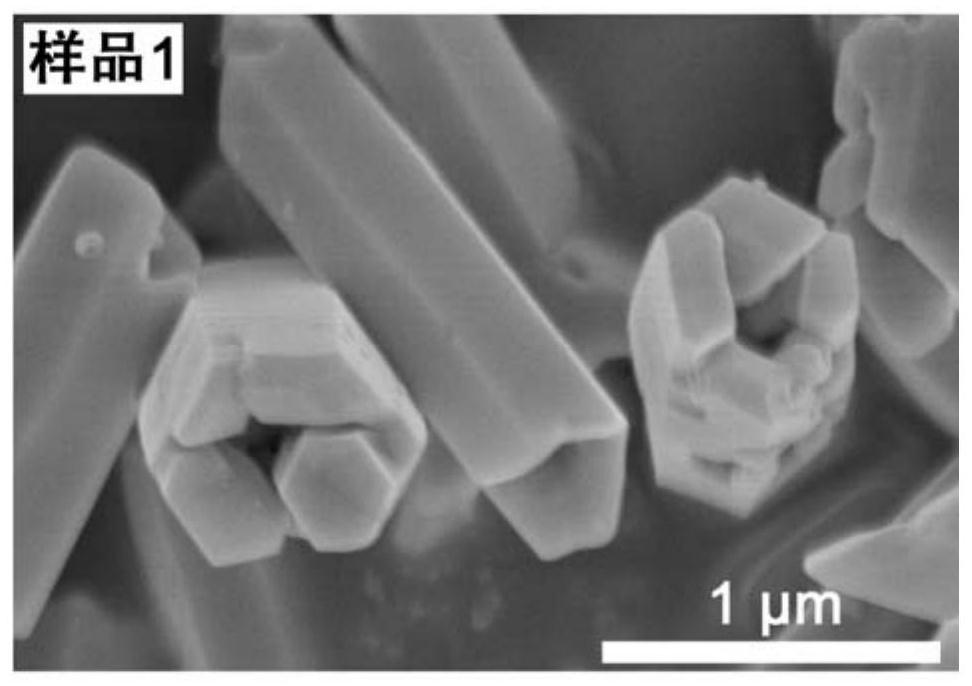

Embodiment 1

[0048] A kind of β-NaGdF provided by this embodiment 4 : Eu 3+ A preparation method for red fluorescence, comprising the steps of:

[0049] (1) 0.2mmol Gd(NO 3 ) 3 ·6H 2 O and 0.1mmol Eu(NO 3 ) 3 ·6H 2 O in 50mL H 2 O, and stirred at a temperature of 30°C to obtain the first solution;

[0050] (2) Add 15 mL of an aqueous solution containing 4 mmol of L-lysine molecules to the first solution and mix to obtain a second solution;

[0051] (3) 1mmolNaCl and 8mmol NH 4 F is added to the second solution and mixed with a large amount of turbidity to obtain a third solution with a large amount of precipitation;

[0052] (4) Put the third solution into a polytetrafluoroethylene reactor, and conduct a hydrothermal reaction at a reaction temperature of 180°C for 24 hours. At this time, whether the reaction raw materials are completely converted into pure phase β-NaGdF 4 , to obtain the fourth solution;

[0053] (5) Filter the fourth solution in turn, and after washing with di...

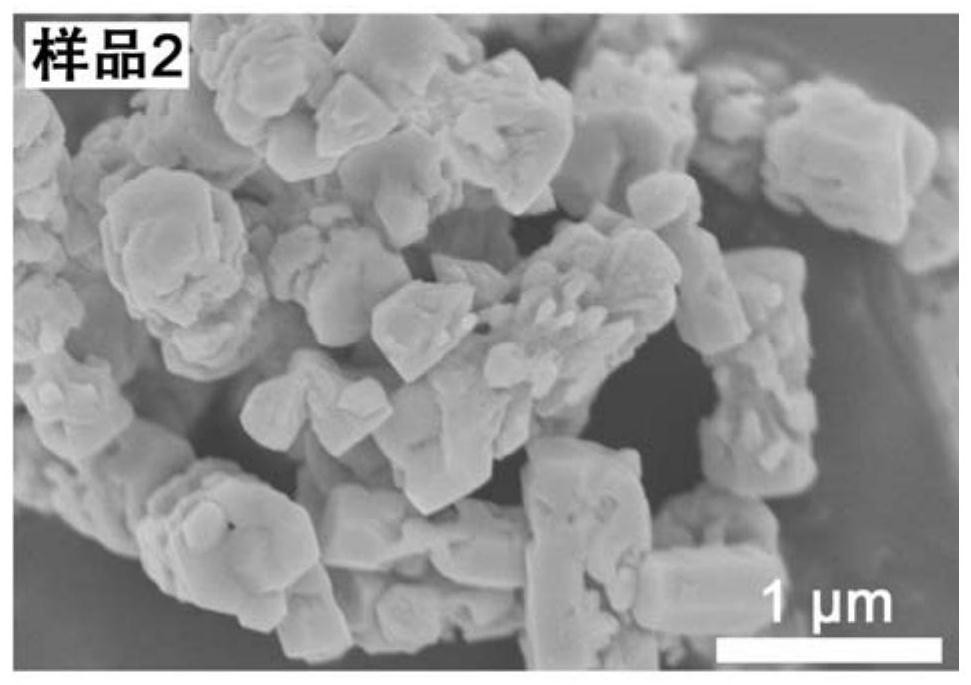

Embodiment 2

[0056] A kind of β-NaGdF provided by this embodiment 4 : Eu 3+ A preparation method for red fluorescence, comprising the steps of:

[0057] (1) 0.2mmol Gd(NO 3 ) 3 ·6H 2 O and 0.1mmol Eu(NO 3 ) 3 ·6H 2 O in 50mL H 2 O, and stirred at a temperature of 30°C to obtain the first solution;

[0058] (2) Add 10 mL of an aqueous solution containing 4 mmol of L-lysine molecules to the first solution and mix to obtain a second solution;

[0059] (3) 1mmolNaCl and 8mmol NH 4 F is added to the second solution and mixed with a large amount of turbidity to obtain a third solution with a large amount of precipitation;

[0060] (4) Put the third solution into a polytetrafluoroethylene reactor, and conduct a hydrothermal reaction at a reaction temperature of 180°C for 24 hours. At this time, whether the reaction raw materials are completely converted into pure phase β-NaGdF 4 , to obtain the fourth solution;

[0061] (5) Filter the fourth solution in turn, and after washing with di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com