Double-sided superposed pipe gallery side wall with embedded columns and manufacturing method thereof

A production method and technology of hidden pillars, which are applied in water conservancy projects, artificial islands, climate change adaptation, etc., can solve the problems of heavy weight of all prefabricated components, reduced waterproof performance of assembly joints, and high transportation costs, and achieve accurate protective layer thickness and self-restraint. Good waterproof performance and the effect of reducing the amount of steel used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0051] Aiming at the problems existing in the prior art, the present invention provides a double-sided laminated pipe gallery side wall with concealed columns and its manufacturing method. The present invention will be described in detail below with reference to the accompanying drawings.

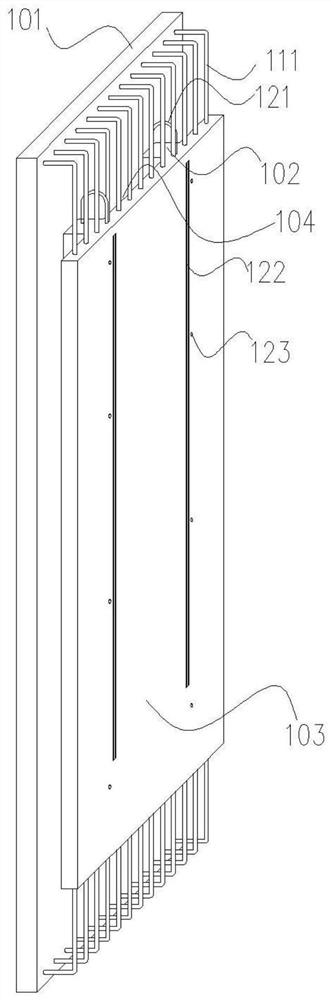

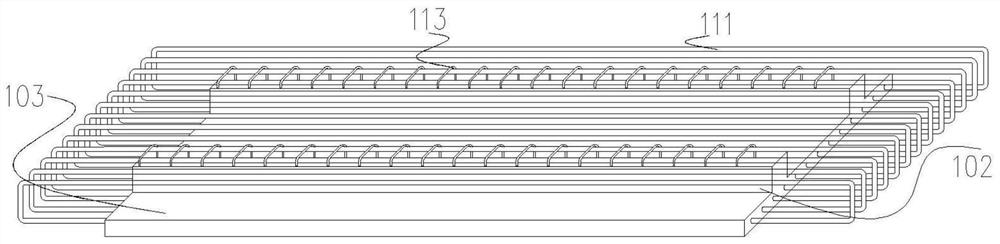

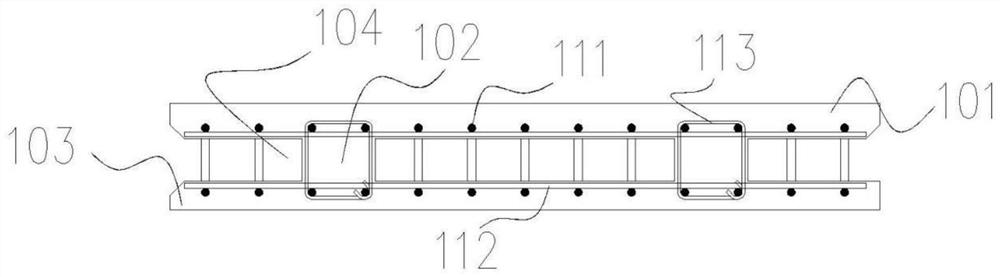

[0052] Such as Figure 1 to Figure 5 As shown, the double-sided laminated pipe gallery side wall with hidden columns provided by the embodiment of the present invention includes an outer prefabricated layer 101, an inner prefabricated layer 103 and a hidden column 102 in the middle;

[0053] The outer prefabricated layer 101, the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com