Heat exchanger capable of automatically defrosting or deicing

A heat exchanger, automatic technology, applied in the direction of indirect heat exchanger, heat exchanger type, heat exchanger shell, etc., can solve the problems of long liquefaction time, large loss of cooling capacity in transmission, etc., to improve heat exchange efficiency and improve Refrigeration efficiency, the effect of reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

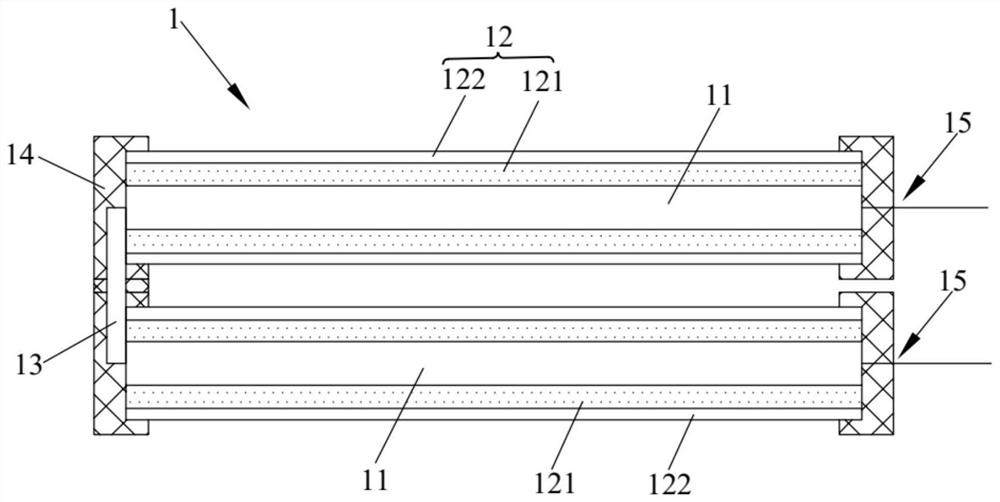

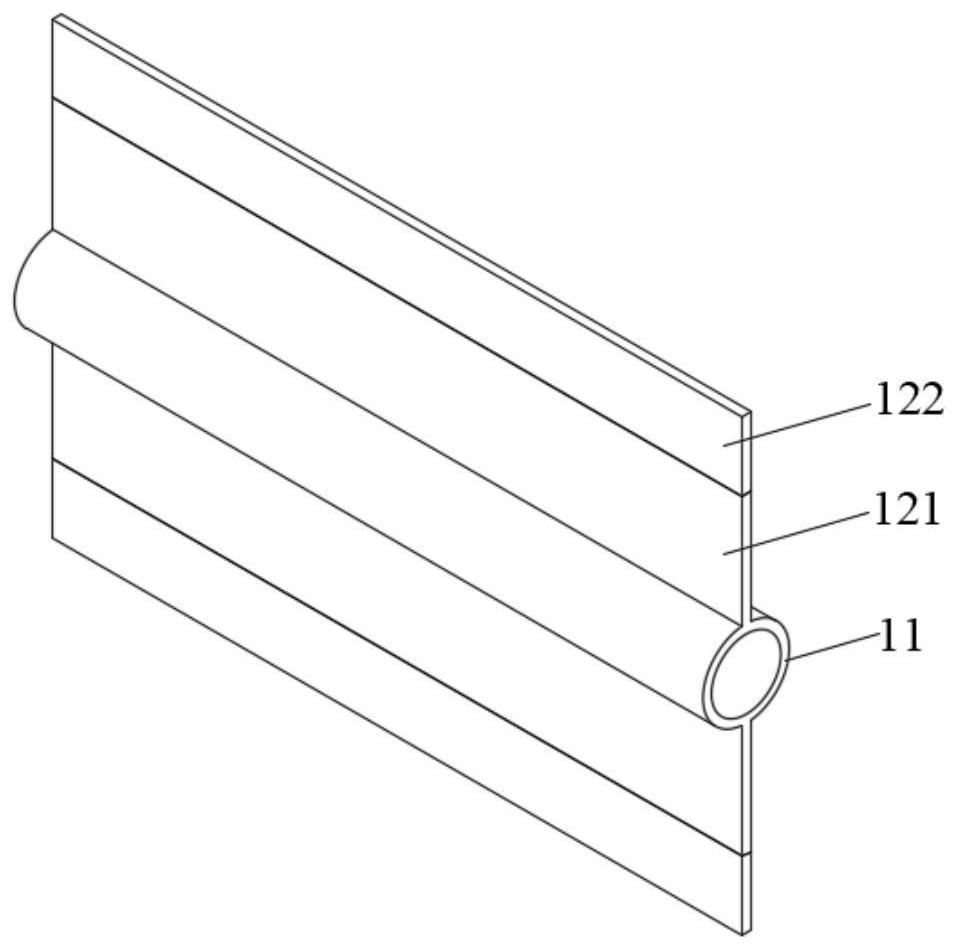

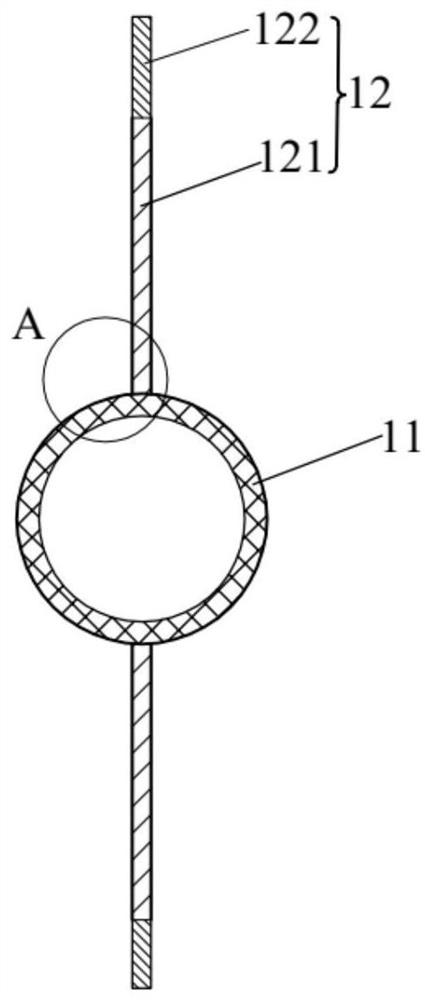

[0037] Such as Figure 1-Figure 4 As shown, this embodiment provides a heat exchanger 1 capable of automatic defrosting or deicing, including a heat exchange assembly, the heat exchange assembly includes a row pipe 11 and fins 12, and brine can be passed into the row pipe 11, The fins 12 are arranged on the outer wall of the row tube 11 , and the height of the fin 12 extends along the radial direction of the row tube 11 . The fins 12 include a first heat conduction part 121 and a second heat conduction part 122 sequentially connected to the exhaust pipe 11 , the thermal conductivity of the second heat conduction part 122 is smaller than the thermal conductivity of the first heat conduction part 121 and the heat conduction coefficient of the exhaust pipe 11 . Both the outer surface of the first heat conducting part 121 and the outer surface of the row pipe 11 are coated with a micron or nanoscale hydrophobic layer 16, and the hydrophobic layer 16 is a hydrophobic coating or a h...

Embodiment 2

[0057] For more controllable and easier removal of ice or frost layers from heat exchanger surfaces, it can be done in conjunction with a heat source. Such as Figure 5 As shown, this embodiment provides a controllable automatic defrosting or deicing heat exchanger system, which includes the heat exchanger 1 provided in Embodiment 1, and also includes a switching valve 2 and a low-temperature cold source and a high-temperature heat source 3 . The low-temperature cold source and the high-temperature heat source 3 are connected to the row pipe 11 through the switching valve 2, so as to feed brine or heat carrier into the row pipe 11. Specifically, in this embodiment, the switching valve 2 is a four-way valve. In the cooling condition, the low-temperature cooling source is connected to the exhaust pipe 11 by switching the switching valve 2, so that the brine is passed into the exhaust pipe 11; in the deicing working condition, by switching the switching valve 2, the The high-te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com