Preparation method of V2O5/Sr2FeTaO6 @ C photocatalyst and photocatalyst and application thereof

A photocatalyst, chloride technology, applied in metal/metal oxide/metal hydroxide catalysts, heterogeneous catalyst chemical elements, physical/chemical process catalysts, etc. Bonding, efficiency needs to be improved and other issues, to achieve the effect of reducing transfer resistance, promoting rapid transfer, and reducing interface transfer resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

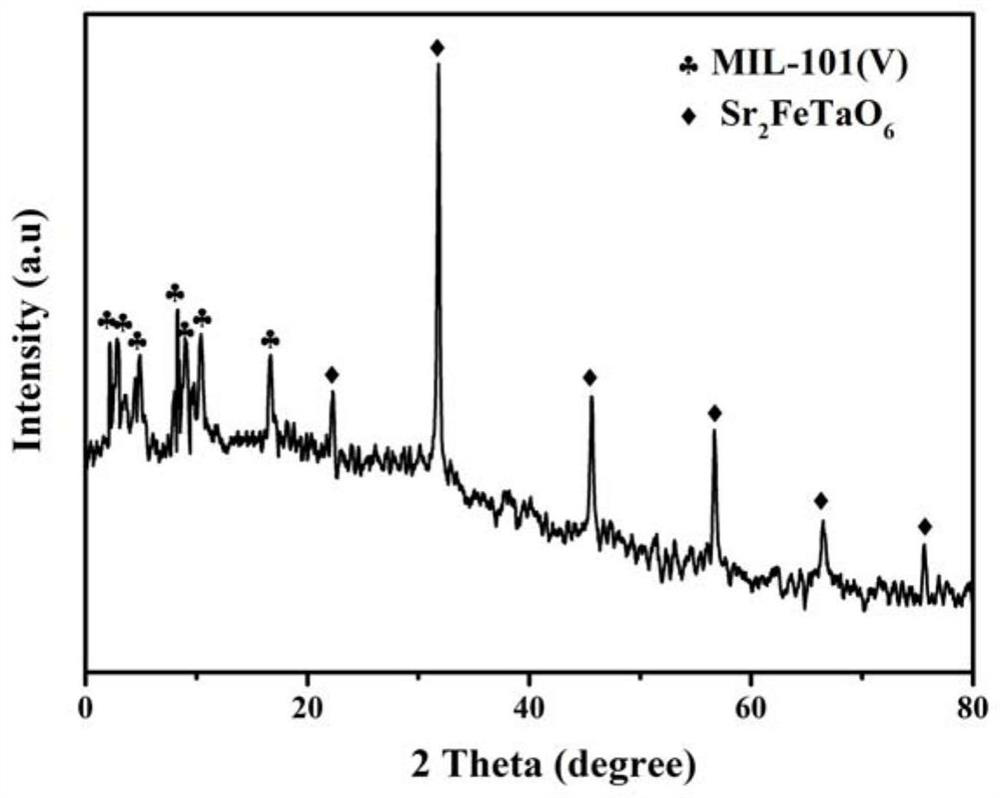

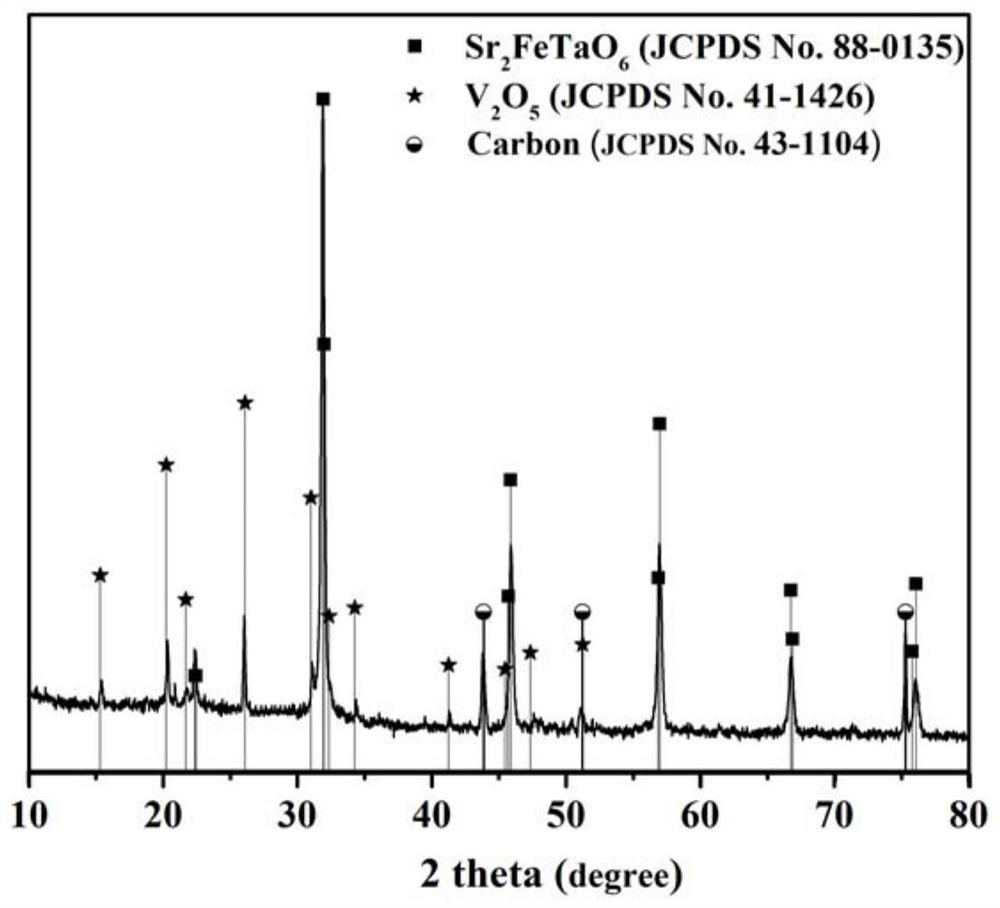

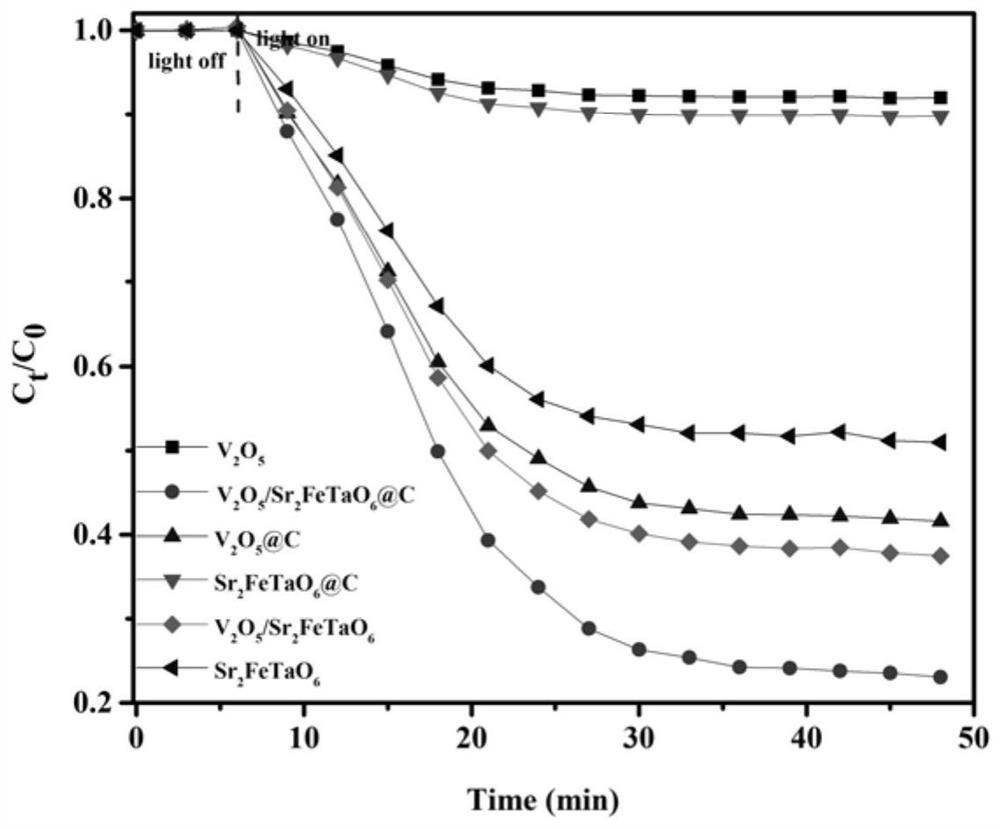

[0045] V 2 o 5 / Sr 2 FeTaO 6 Preparation of @C Photocatalyst and Evaluation of Nitrogen Oxide Degradation

[0046] (1) Add 15mL of deionized water to 45mL of absolute ethanol, and configure an aqueous ethanol solution with a volume ratio of 1:3;

[0047] (2) Add 200 mg of vanadium acetylacetonate to the above solution, then add 144 mg of 1,3,5-benzenetricarboxylic acid and 66 mg of NaCl, and stir for about 12 hours to completely dissolve it;

[0048] (3) Add 30% dilute HCl by volume fraction to the solution obtained in step (2), and adjust the pH value of the solution to 2.5;

[0049] (4) Add the prepared 1g Sr 2 FeTaO 6 Powder particles, fully stirred;

[0050] (5) Transfer the mixed suspension obtained in step (4) to a hydrothermal kettle for hydrothermal reaction, and react at 180°C for 15 hours. After the reaction is completed, wait for it to cool naturally, rinse the solid repeatedly with absolute ethanol and water, and dry to obtain MIL -101(V) / Sr 2 FeTaO 6 Pow...

Embodiment 2

[0075] Identical to the preparation method of Example 1, the difference is that the addition of vanadium acetylacetonate is changed, specifically as follows:

[0076] serial number sample Sr 2 FeTaO 6 amount

Embodiment 3

[0078] (1) Add 15mL of deionized water to 45mL of absolute ethanol, and configure an aqueous ethanol solution with a volume ratio of 1:3;

[0079] (2) Add 200 mg of vanadium acetylacetonate to the above solution, then add 60 mg of 1,3,5-benzenetricarboxylic acid and 66 mg of NaCl, and stir for about 12 hours to completely dissolve it;

[0080] (3) Add 30% dilute HCl to the solution obtained in step (2), and adjust the pH value of the solution to 2.5;

[0081] (4) Add the prepared 1g Sr 2 FeTaO 6 Powder particles, fully stirred;

[0082] (5) Transfer the mixed suspension obtained in step (4) to a hydrothermal kettle for hydrothermal reaction, and react at 180°C for 15 hours. After the reaction is completed, wait for it to cool naturally, rinse repeatedly with absolute ethanol and water, and dry to obtain MIL- 101(V) / Sr 2 FeTaO 6 Powder;

[0083] (6) MIL-101(V) / Sr obtained in step (5) 2 FeTaO 6 After the powder sample is fully ground, it is transferred to a tube furnace,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com