Preparation method and application of dodecahedral zinc oxide nano material

A zinc oxide nano and dodecahedron technology, applied in zinc oxide/zinc hydroxide, nanotechnology, analytical materials, etc., to achieve the effect of improving gas sensing sensitivity and structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Dissolve 1.116 g of zinc nitrate hexahydrate in 60 mL of anhydrous methanol and stir for 5 min to obtain solution A;

[0036] (2) Dissolve 1.232 g of 2-methylimidazole in 60 mL of anhydrous methanol and stir for 5 min to obtain solution B;

[0037] (3) Add the B solution obtained in step (2) to the A solution obtained in step (1) at a rate of two seconds per drop using a separating funnel, and then continuously stir at 600 r / min at 25 °C for 24 h to carry out complexation reaction , after the reaction, the centrifuged white precipitate was washed three times with anhydrous methanol;

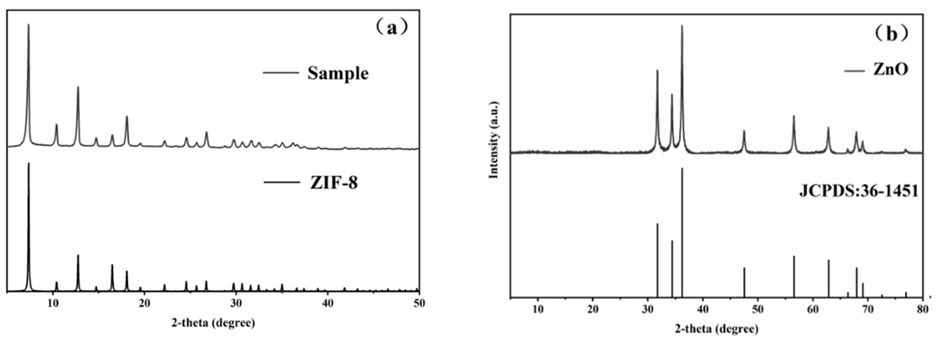

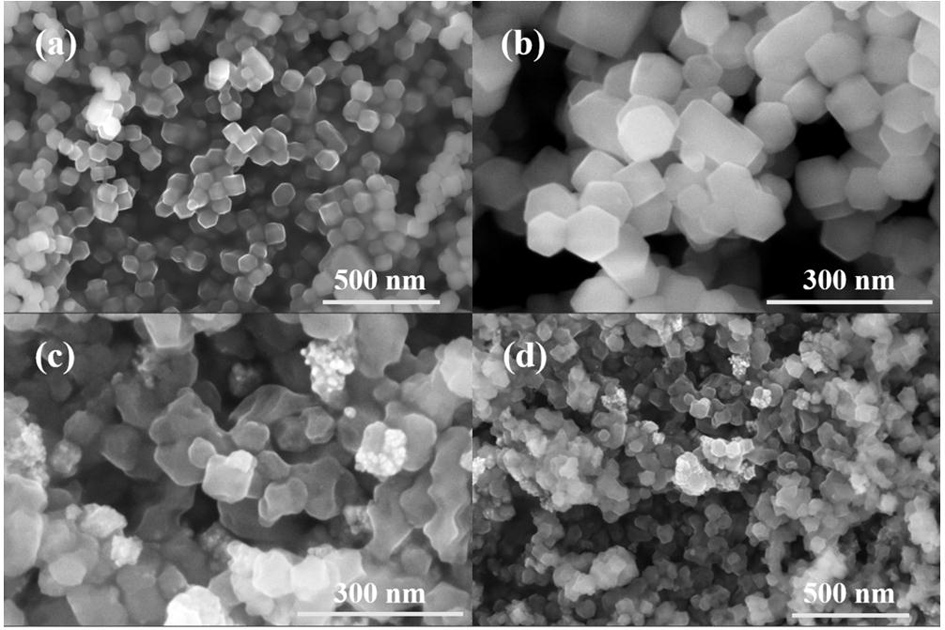

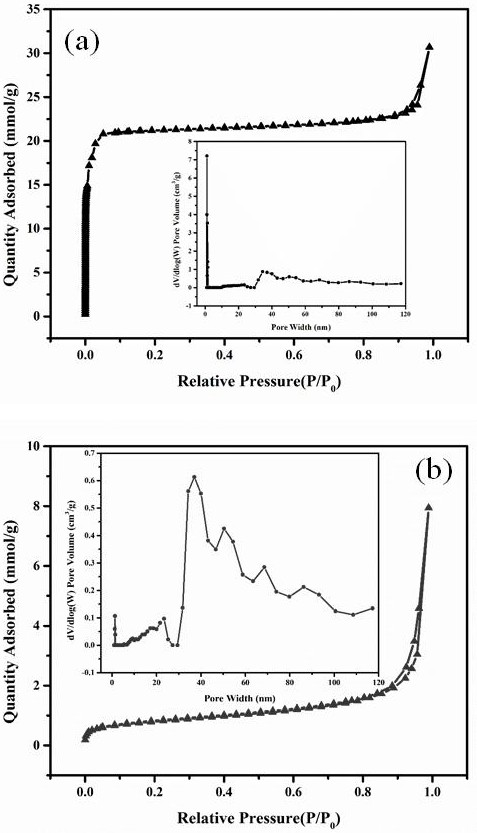

[0038] (4) Dry the white precipitate after washing in step (3) in a vacuum oven at 60 °C for 24 h. After drying, grind it with a mortar for 30 min. Under protection, the temperature was raised to 400 °C at 2 °C / min and calcined for 2 h, and then air was introduced to continue calcining for 2 h. The final powder obtained was the zinc oxide nanomaterial used to prepare the gas sensor. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com