Method for preparing pentanediamine by catalyzing lysine decarboxylation with solid superacid

A technology of strong acid catalyzing lysine, solid super acid, applied in catalyst activation/preparation, chemical instruments and methods, preparation of amino compounds from amines, etc., to achieve the effects of easy separation, solving equipment corrosion problems, and good environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

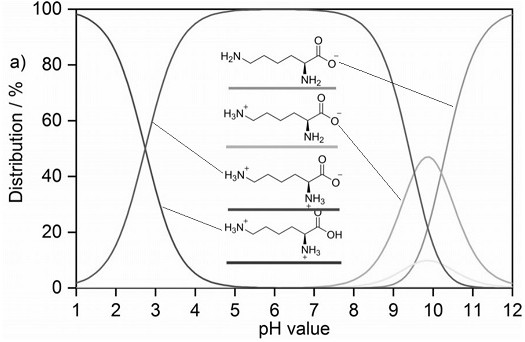

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A kind of method that solid superacid catalyst catalyzes decarboxylation of lysine to prepare pentamethylenediamine, the steps are as follows:

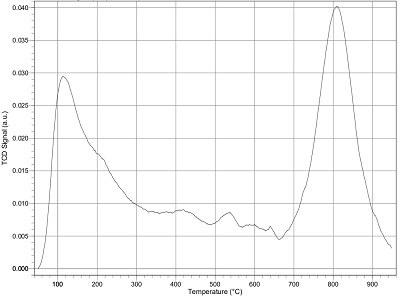

[0026] (1) SO 4 2- -ZrO 2 Preparation of solid superacid carrier

[0027] Preparation of zirconium hydroxide precursor:

[0028] A certain amount of zirconium oxychloride octahydrate solid was weighed and dissolved in deionized water, and stirred at a constant speed until the solution was clear to obtain a 0.4 mol / L zirconium oxychloride aqueous solution. While stirring, add concentrated ammonia water dropwise until a thick suspension is formed. Stop adding concentrated ammonia water dropwise when pH=9, and continue stirring for 15 min. After standing for 24 h, filter and wash, and remove water in an oven at 120 °C for 12 h.

[0029] SO 4 2- -ZrO 2 Preparation of solid superacid carrier:

[0030] The above-mentioned zirconium hydroxide precursor was fully ground to powder, and impregnated with 1 mol / L sulfuric acid so...

Embodiment 2

[0038] A kind of method that solid superacid catalyst catalyzes decarboxylation of lysine to prepare pentamethylenediamine, the steps are as follows:

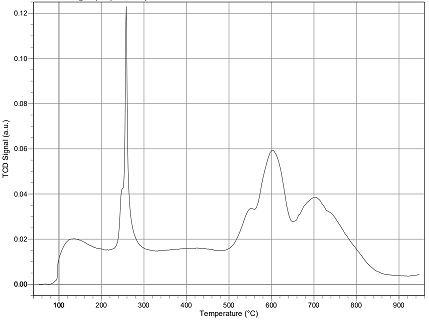

[0039] (1) Fe / SO 4 2- -ZrO 2 Catalyst preparation

[0040] SO 4 2- -ZrO 2 Carrier and 5wt%Fe / SO 4 2- -ZrO 2 The preparation method is the same as in Example 1.

[0041] (2) Decarboxylation of lysine to pentamethylenediamine reaction

[0042] Take 1 mmol of lysine and 10 mL of water in a reaction kettle with a volume of 25 mL, stir until the raw material of lysine is completely dissolved, and add a certain amount of 5wt% Fe / SO 4 2- -ZrO 2 Catalyst, wherein the molar ratio of Fe element to lysine is 0.005, stirred for 5 min. After sealing the reaction kettle, the air in the kettle was replaced with hydrogen, then the pressure was increased to 2 MPa, the temperature was raised to 150 °C, the stirring speed was 800 r / min, and the reaction was stopped after 6 hours. The concentration of pentamethylenediamine in the rea...

Embodiment 3

[0044] A kind of method that solid superacid catalyst catalyzes decarboxylation of lysine to prepare pentamethylenediamine, the steps are as follows:

[0045] (1) Fe / SO 4 2- -ZrO 2 Catalyst preparation

[0046] SO 4 2- -ZrO 2 Carrier and 5wt%Fe / SO 4 2- -ZrO 2 The preparation method is the same as in Example 1.

[0047] (2) Decarboxylation of lysine to pentamethylenediamine reaction

[0048] Take 1 mmol of lysine and 10 mL of water in a reaction kettle with a volume of 25 mL, stir until the raw material of lysine is completely dissolved, and add a certain amount of 5wt% Fe / SO 4 2- -ZrO 2 Catalyst, wherein the molar ratio of Fe element to lysine is 0.05, stirred for 5 min. After sealing the reaction kettle, the air in the kettle was replaced with hydrogen, then the pressure was increased to 2 MPa, the temperature was raised to 150 °C, the stirring speed was 800 r / min, and the reaction was stopped after 6 hours.

[0049] The concentration of pentamethylenediamine in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com