Preparation method applied to silkworm fiber material

A fiber material and silk fiber technology, which is applied in the field of preparation of sericulture fiber materials, can solve the problems of low use value, low silk yield, inferior comfort, etc., and achieves the effects of high use value, good comprehensive characteristics and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

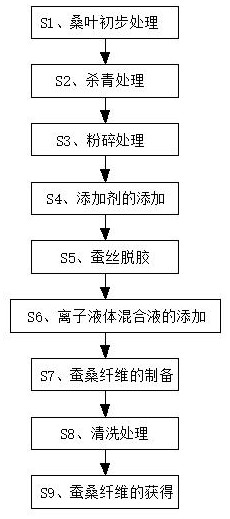

[0029] Example 1: Please refer to figure 1 , the invention discloses a preparation method applied to silkworm and mulberry fiber materials, comprising the following steps:

[0030] S1. Preliminary treatment of mulberry leaves: after picking mulberry leaves, wash and dry and remove diseased and insect leaves, cut mulberry leaves into strips with an automatic mulberry cutting machine, and remove the main veins of mulberry leaves;

[0031] S2, finishing treatment: the strip-shaped mulberry leaves prepared in step S1 are processed with a steam-fixing machine, the strip-shaped mulberry leaves after finishing are kneaded, and then dried, and the processing time of the mulberry leaves is 30-50s , the temperature of the drying treatment is 50°C, and the drying is performed until the moisture content of the mulberry leaves is 5.5%;

[0032] S3, crushing treatment: the dried mulberry leaves in step S2 are crushed with an ultrafine pulverizer, the time for crushing the mulberry leaves i...

Embodiment 2

[0039] Example 2: Please refer to figure 1 , the invention discloses a preparation method applied to silkworm and mulberry fiber materials, comprising the following steps:

[0040] S1. Preliminary treatment of mulberry leaves: after picking mulberry leaves, wash and dry and remove diseased and insect leaves, cut mulberry leaves into strips with an automatic mulberry cutting machine, and remove the main veins of mulberry leaves;

[0041]S2, finishing treatment: the strip-shaped mulberry leaves prepared in step S1 are processed with a steam-fixing machine, the strip-shaped mulberry leaves after finishing are kneaded, and then dried. The temperature of the drying treatment is 60°C, and the drying is carried out until the moisture content of the mulberry leaves is 6.0%;

[0042] S3, pulverization treatment: the mulberry leaves dried in step S2 are pulverized with an ultrafine pulverizer, the time for the mulberry leaves pulverization treatment is 8 minutes, and the pulverized mul...

Embodiment 3

[0049] Example 3: Please refer to figure 1 , the invention discloses a preparation method applied to silkworm and mulberry fiber materials, comprising the following steps:

[0050] S1. Preliminary treatment of mulberry leaves: after picking mulberry leaves, wash and dry and remove diseased and insect leaves, cut mulberry leaves into strips with an automatic mulberry cutting machine, and remove the main veins of mulberry leaves;

[0051] S2, finishing treatment: the strip-shaped mulberry leaves prepared in step S1 are processed with a steam-fixing machine, the strip-shaped mulberry leaves after finishing are kneaded, and then dried, and the processing time of the mulberry leaves is 30-50s , the temperature of the drying treatment is 70°C, and the drying is performed until the moisture content of the mulberry leaves is 6.5%;

[0052] S3, crushing treatment: the dried mulberry leaves in step S2 are crushed with an ultrafine pulverizer, the time for crushing the mulberry leaves i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com