Light-emitting diode and manufacturing method thereof

A technology of light-emitting diodes and manufacturing methods, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of poor current spreading effect and large internal resistance of light-emitting diodes, and achieve fewer failed particles, reduce square resistance, and facilitate production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

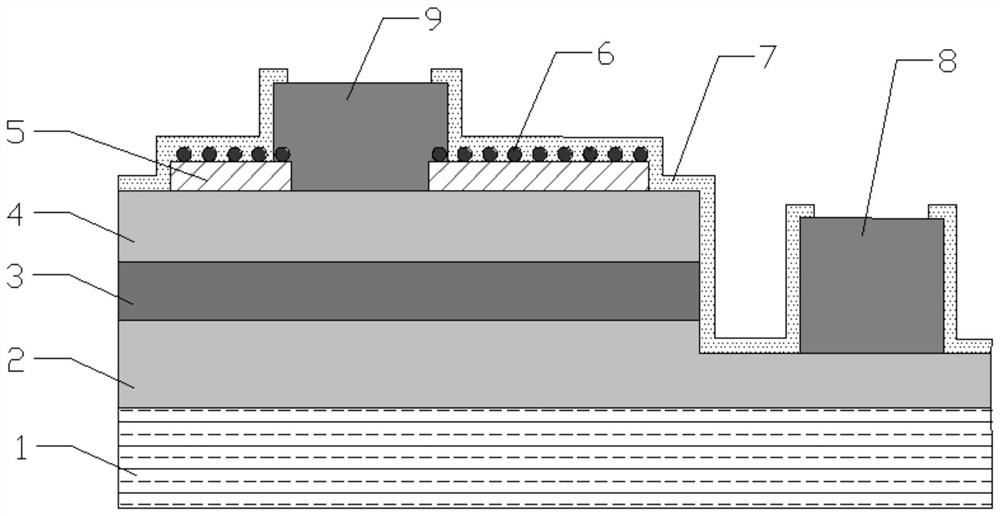

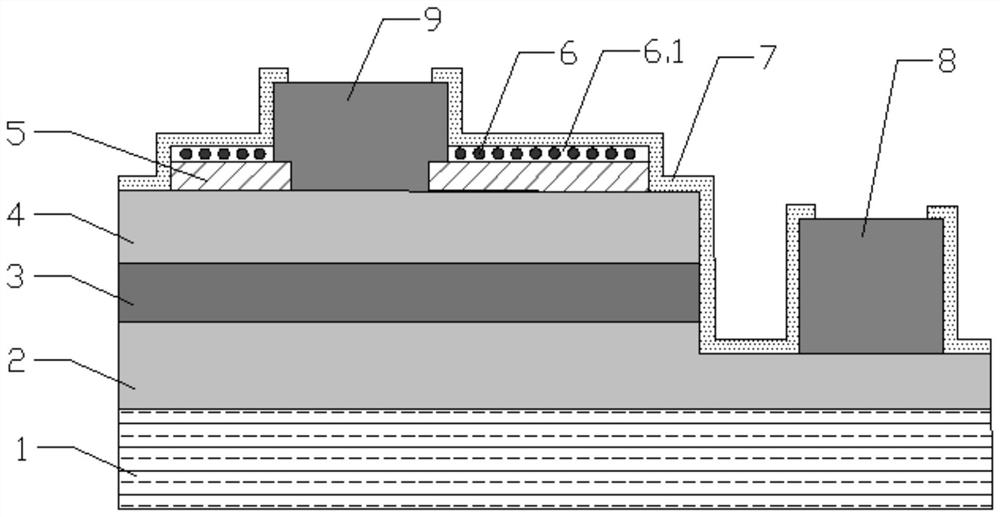

[0058] like figure 1 As shown, a light-emitting diode, the light-emitting diode is a horizontal structure, which includes:

[0059] substrate1;

[0060] A light-emitting structure A disposed on the surface of a substrate 1; the light-emitting structure A at least includes a first-type semiconductor layer 2, an active region 3, and a second-type semiconductor layer 4 stacked in sequence along a first direction; the first direction is perpendicular to the substrate 1 , and point to the light-emitting structure A from the substrate 1;

[0061] The nanosystem, the nanosystem is laminated on at least one surface of the light-emitting structure A, and the free vibration frequency of the nanosystem matches the photon frequency of the incident light of the light-emitting structure A; optionally, the free vibration frequency of the nanosystem is greater than or equal to the specified The incident light photon frequency of the light-emitting structure induces the electrons of the nano...

Embodiment 2

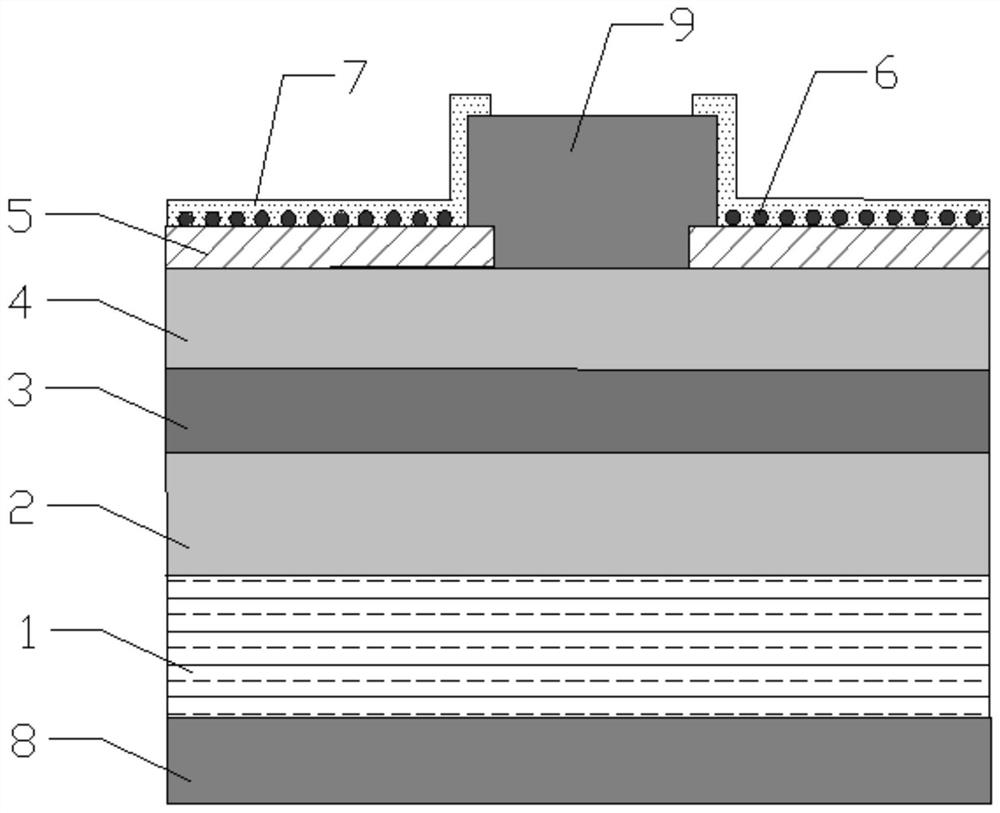

[0096] like image 3 As shown, a light-emitting diode, the light-emitting diode is a vertical structure, which includes:

[0097] substrate1;

[0098]A light-emitting structure A disposed on the surface of a substrate 1; the light-emitting structure A at least includes a first-type semiconductor layer 2, an active region 3, and a second-type semiconductor layer 4 stacked in sequence along a first direction; the first direction is perpendicular to the substrate 1 , and point to the light-emitting structure A from the substrate 1;

[0099] A nanosystem, where the nanosystem is stacked on at least one surface of the light-emitting structure A, and the free vibration frequency of the nanosystem matches the photon frequency of the incident light of the light-emitting structure A;

[0100] The first electrode 8, the first electrode 8 is stacked on the surface of the light emitting structure A, and forms an ohmic contact with the second type semiconductor layer 4;

[0101] The sec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com