Catalytic cracking catalyst as well as preparation method and application thereof

A catalytic cracking and catalyst technology, applied in catalytic cracking, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve the problems of insufficient improvement of ethylene yield and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

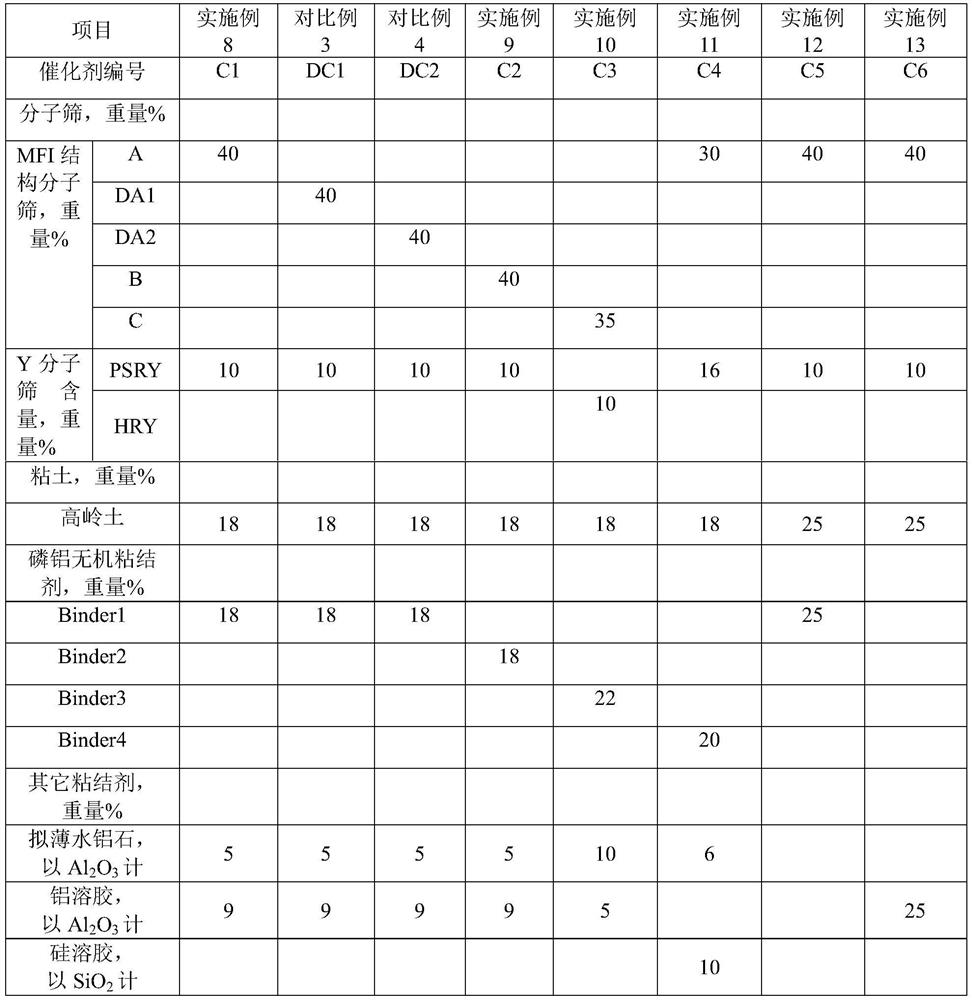

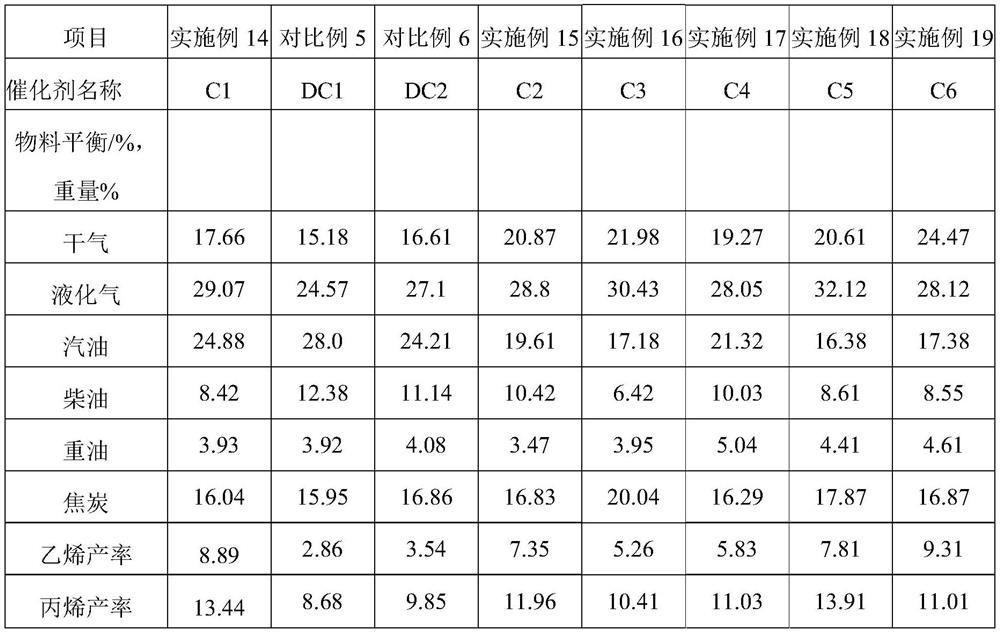

Examples

Embodiment approach

[0059] A specific embodiment, based on the dry basis weight of the phosphorus-aluminum inorganic binder, the phosphorus-aluminum inorganic binder includes Al 2 o 3 15-40% by weight aluminum component, with P 2 o5 45-80% by weight of the phosphorus component and 0-40% by weight of the first clay based on dry weight, and its P / Al weight ratio is 1.0-6.0, the pH value is 1-3.5, and the solid content is 15- 60% by weight; for example including Al 2 o 3 15-40% by weight aluminum component, with P 2 o 5 45-80% by weight of the phosphorus component and 1-40% by weight of the first clay on a dry basis; preferably containing Al 2 o 3 15-35% by weight of the aluminum component, as P 2 o 5 50-75% by weight of the phosphorus component and 8-35% by weight of the first clay based on dry weight, and its P / Al weight ratio is preferably 1.2-6.0, more preferably 2.0-5.0, and the pH value is preferably 1.5-3.0.

[0060] Another specific embodiment, based on the dry basis weight of the ...

Embodiment 1

[0113] Crystallized ZSM-5 molecular sieve (produced by Catalyst Qilu Branch Company, synthesized without amine method, n(SiO 2 ) / n(Al 2 o 3 )=27) filter out mother liquor, wash with water to Na 2 O content is lower than 5.0% by weight, and filter cake is obtained by filtration; Get above-mentioned molecular sieve 100g (dry basis) and add in 1000g 2.0% NaOH solution, heat up to 65 ℃, after reacting for 30min, after rapidly cooling to room temperature, filter, wash to filtrate neutral. Then, add 800g water to the filter cake to make a slurry, add 40g NH 4 Cl, heated to 75°C, exchanged for 1h, to Na 2 O content is lower than 0.2% by weight, filters, washes, and obtains molecular sieve filter cake; Get above-mentioned molecular sieve filter cake 50g (dry basis), filter cake is added water beating and obtains the molecular sieve slurry that solid content is 40% by weight, adds 9.7g H 3 PO 4 (concentration 85% by weight) and 8.1gLa (NO 3 ) 3 ·6H 2 O, mix evenly, impregnate,...

Embodiment 2

[0115] Crystallized ZSM-5 molecular sieve (produced by Catalyst Qilu Branch Company, synthesized without amine method, n(SiO 2 ) / n(Al 2 o 3 )=27) filter out mother liquor, wash with water to Na 2 O content is lower than 5.0% by weight, and filter cake is obtained by filtration; Get above-mentioned molecular sieve 100g (dry basis) and add in 1000g 2.0% NaOH solution, heat up to 65 ℃, after reacting for 30min, after rapidly cooling to room temperature, filter, wash to filtrate neutral. Then, add 800g water to the filter cake to make a slurry, add 40g NH 4 Cl, heated to 75°C, exchanged for 1h, to Na 2 O content is lower than 0.2% by weight, filters, washes, and obtains molecular sieve filter cake; Get above-mentioned molecular sieve filter cake 50g (dry basis), filter cake is added water beating and obtains the molecular sieve slurry that solid content is 40% by weight, adds 5.8g H 3 PO 4 (Concentration 85% by weight) and 4.9gCe(NO 3 ) 2 ·6H 2 O, mix evenly, impregnate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com