Material cleaning method for machining of semiconductor chip grinding equipment rack

A technology for processing materials and semiconductors, which is applied in the field of material cleaning for the processing of semiconductor chip grinding equipment racks, can solve the problems of inability to perform deep cleaning and insufficient cleaning, and achieve the effects of saving resources, fast drying and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

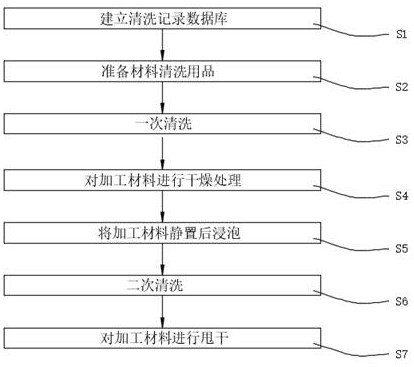

[0029] see figure 1 , the present invention also provides a technical solution: a material cleaning method for semiconductor chip grinding equipment frame processing, comprising the following steps:

[0030] S1. Cleaning record: establish a cleaning record database;

[0031] S2. Cleaning preparation: prepare material cleaning supplies, and place materials processed by semiconductor chip grinding equipment racks;

[0032] S3, one-time cleaning: put the semiconductor chip grinding equipment frame processing materials into the ultrasonic cleaning machine, set the cleaning time, set the cleaning temperature, add cleaning liquid, and record the cleaning times;

[0033] S4. Drying treatment: Manually wipe the cleaning liquid on the surface of the processing material of the semiconductor chip grinding equipment rack, put it into the dryer after wiping, set the drying time; record the drying times;

[0034] S5. Soaking: put the processed material of the semiconductor chip grinding e...

Embodiment 2

[0045] The present invention also provides a figure 1 A material cleaning method for semiconductor chip grinding equipment frame processing shown, comprising the following steps:

[0046] S1. Cleaning record: establish a cleaning record database;

[0047] S2. Cleaning preparation: prepare material cleaning supplies, and place materials processed by semiconductor chip grinding equipment racks;

[0048]S3, one-time cleaning: put the semiconductor chip grinding equipment frame processing materials into the ultrasonic cleaning machine, set the cleaning time, set the cleaning temperature, add cleaning liquid, and record the cleaning times;

[0049] S4. Drying treatment: Manually wipe the cleaning liquid on the surface of the processing material of the semiconductor chip grinding equipment rack, put it into the dryer after wiping, set the drying time; record the drying times;

[0050] S5. Soaking: put the processed material of semiconductor chip grinding equipment rack after dryin...

Embodiment 3

[0061] The present invention also provides a figure 1 A material cleaning method for semiconductor chip grinding equipment frame processing shown, comprising the following steps:

[0062] S1. Cleaning record: establish a cleaning record database;

[0063] S2. Cleaning preparation: prepare material cleaning supplies, and place materials processed by semiconductor chip grinding equipment racks;

[0064] S3, one-time cleaning: put the semiconductor chip grinding equipment frame processing materials into the ultrasonic cleaning machine, set the cleaning time, set the cleaning temperature, add cleaning liquid, and record the cleaning times;

[0065] S4. Drying treatment: Manually wipe the cleaning liquid on the surface of the processing material of the semiconductor chip grinding equipment rack, put it into the dryer after wiping, set the drying time; record the drying times;

[0066] S5. Soaking: Put the processed material of semiconductor chip grinding equipment rack after dryi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com