A device and method for fully automatic control of selective wave soldering

A wave soldering, selective technology, applied in the direction of welding equipment, electric heating devices, auxiliary devices, etc., can solve the problem of not being able to save flux energy consumption, etc., to reduce welding operating costs, save labor costs, and adjustable heating power Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

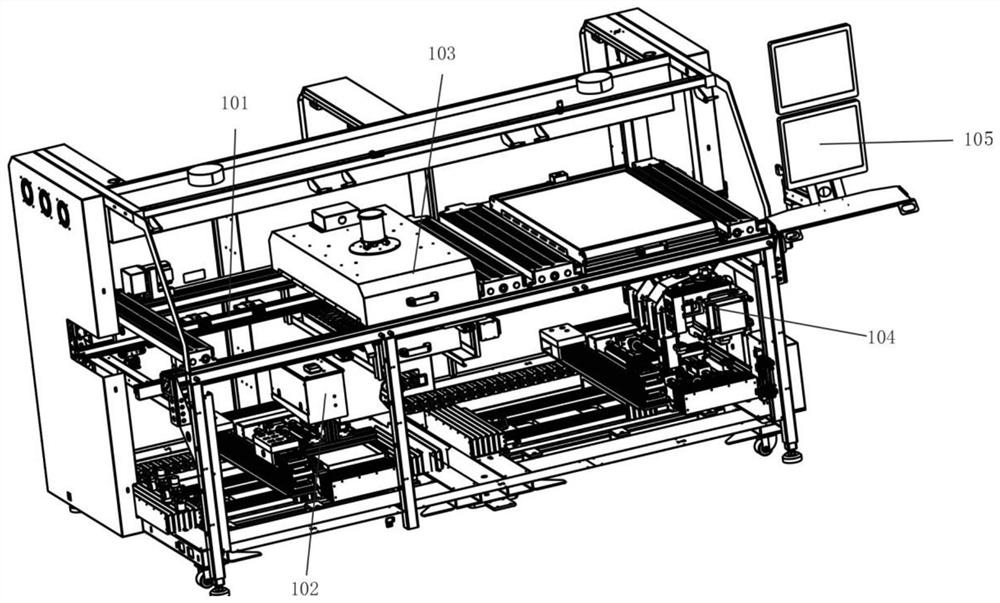

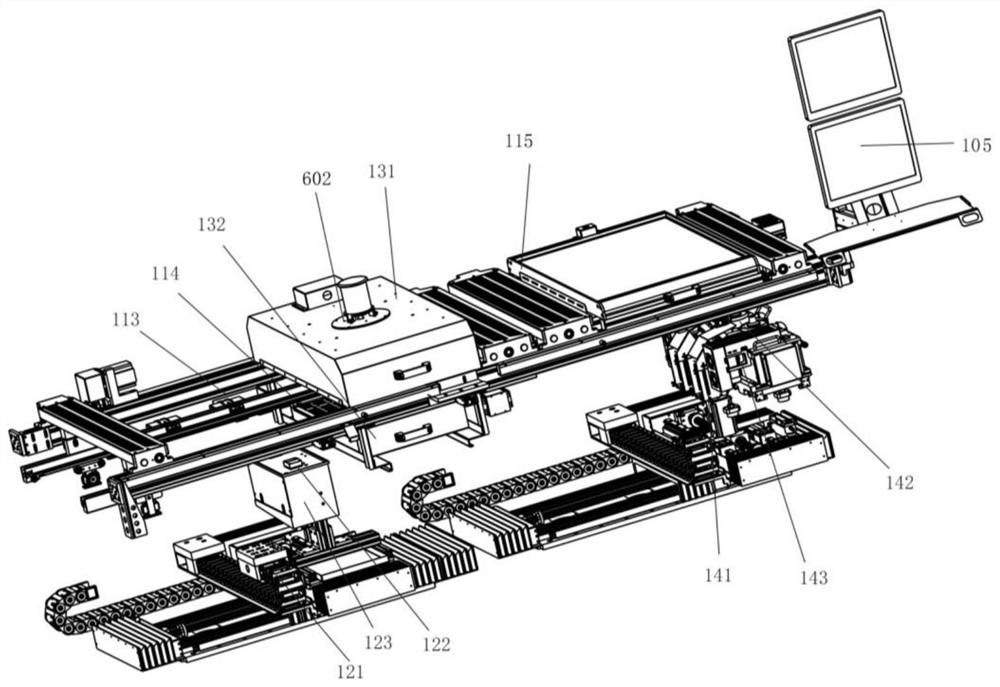

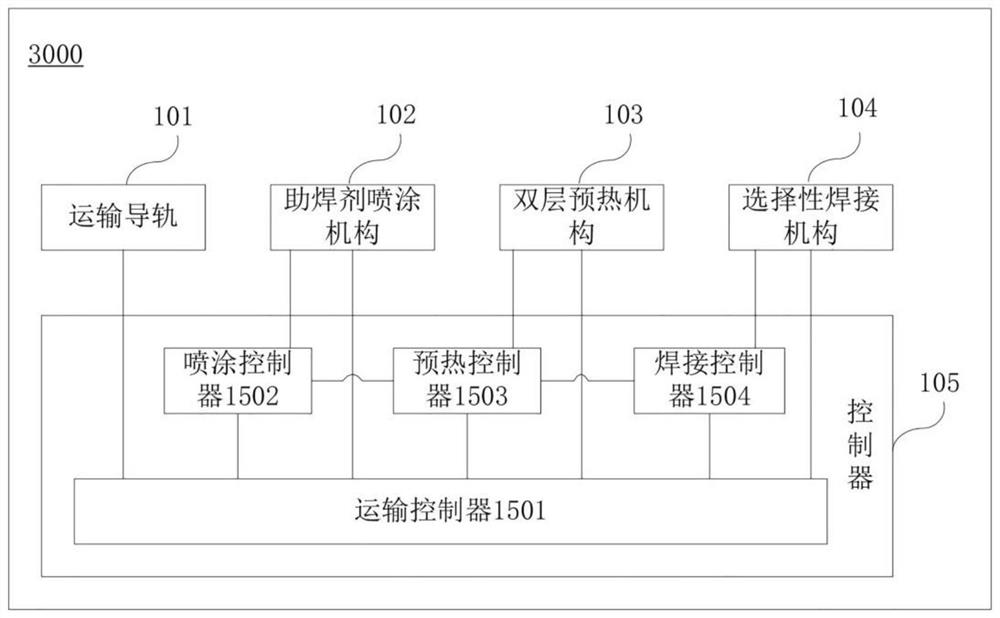

[0077] Such as Figures 1 to 3 as shown, figure 1 It is a structural schematic diagram of a fully automatic selective wave soldering device in this embodiment; figure 2 It is a structural schematic diagram of a spraying, preheating and welding mechanism of the fully automatic selective wave soldering device in this embodiment; image 3 It is a schematic structural diagram of a device for fully automatic control of selective wave soldering in this embodiment.

[0078] Specifically, the device 3000 for fully automatic control of selective wave soldering includes: a controller 105 , a transport rail 101 , a flux spraying mechanism 102 , a double-layer preheating mechanism 103 and a selective soldering mechanism 104 . Wherein, the controller 105 includes: a transportation controller 1501 , a spraying controller 1502 , a preheating controller 1503 and a welding controller 1504 .

[0079] The transportation controller 1501 is connected with the transportation guide rail 101, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com